German alloy mountain bike maker Nicolai’s catalog in filled mostly with aggressive trail and gravity bikes. So it’s probably no surprise that when they wanted to build a new full-suspension cross-country bike, they would lean towards trail riding as well. The new Nicolai Saturn 11 XC bike then matches a 105mm travel Horst link frame with 120mm travel forks and accompanying modern trail geometry. That means a bike ready to race XC and marathons, but just as happy to serve as your all day ride for all around trail mountain biking…

The 29er Saturn 11 opts for a classic Horst link 4-bar suspension design for the butted aluminum frame with its machined rocker, chainstay yoke & dropouts. Designed for mountain bikers that want to hit the trails fast, but aren’t really into the Enduro thing, the new Saturn is a bit of an XC racers do-it-all trail bike. Nicolai calls it the perfect blend of the “efficiency of a marathon race bike and the aggression of the modern trail bike”.

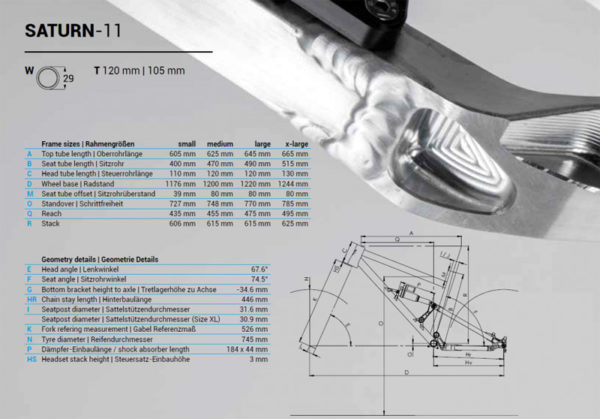

It gets 105mm or rear wheel travel designed to mate well with the slack head angle, steep seat angle, and low bb. The Saturn still fits a bottle in the main triangle, and tacks on another set of bosses under the downtube for riders looking to ditch the Camelbak. The bike gets a Boost spaced rear end, states a max 2.3″ tire, and while the stock bikes don’t get spec’d with dropper seatposts, stealth routing is available. Cable routing is for the most part external with full length housing along modular clamps inside of the main triangle.

The Saturn 11 is available as a 2.75kg (including a Fox DPS rear shock) frame without a shock for 2500€, with frame, shock & fork options or in one of two complete builds.

The top Raceline build will set you back 6500€ at a claimed 10.6kg complete weight and comes kitted out with a premium build. That includes a Fox Factory 32 Float 120mm fork and 3-position Float DPS shock, plus a X01 Eagle drivetrain, Magura MT8 Carbon brakes, and a full super light Tune cockpit and wheelset built with Stan’s Crest rims.

For a more reasonable 4800€ you get the same frame in a Techline build, going with a 120mm RockShox Reba RL fork and Monarch RT3 rear shock. The 12.6kg Techline bike gets a Shimano SLX double drivetrain, MT4 brakes, and Hope Tech XC wheels.

The Saturn 11 is a stock production bike that comes in five frame sizes from S to XXL. The standard butted tubeset frame (as well as the light weight Raceline complete build) has a rider+gear weight limit of 100kg, but they can build a straight gauge frame for bigger riders. Nicolai can also do a bit more customization and will even build one for you with a heavier front triangle for those looking to build one up with a Lefty fork. They also let you pick and choose how you want your cable routing set up. Colors on offer are almost entirely up to the buyer, even down to different colors for front, rear & rocker. There are almost 30 stock colors available in either matte or glossy, plus a couple of anodized colors for no upcharge. Or you can get a premium camo or totally custom color, or their Extra Love anodized hardware for a bit more.