In the past ten years, a lot has changed for ENVE Composites. Their name changed from EDGE to ENVE, facilities have changed as they continued to grow, but one thing remains the same – ENVE’s carbon rims are still made in the USA. That poses a problem for a rapidly growing company as production begins to be limited by the space allowed by their building. Just in time to celebrate their 10th anniversary, ENVE completed work on an all new facility in Ogden, UT. A clean sheet design built specifically around product design and manufacturing, ENVE has doubled their space and even has the option of expanding in the future if business continues to flourish.

Even from the outside, the new ENVE facility is an impressive structure with spectacular views of the nearby mountains. Blending the modernity of composites engineering with Ogden’s history through the remnants of the old Ogden Trackline, ENVE is right at home in their new digs. Roughly 73,000 sq ft, the increase from 35,000 seems greatly welcomed by the employees, and concrete footings have already been poured to allow for future expansion. Capable of producing some 120,000 rims annually, current production is somewhere around 40-70k.

As you walk in the front door, to your right is a studio space with bike storage and enough room for a number of activities. During their 10 year anniversary celebration, the space was being used as part of the Speedvagen fitting tour, with Sacha White continuing on to Texas afterwards. The tour is a chance for potential Speedvagen owners to be properly fit, meet Sacha, and get a look at the bikes first hand. Naturally, there were a number of Speedvagens around the ENVE HQ during the celebration.

In addition to a number of bikes fitted with ENVE components and autographed jerseys of ENVE sponsored teams over the years, there were a few things about the new space that are uniquely ENVE. Like these carbon hand rails. Apparently, when the building was being constructed the contractors wanted to use wooden railings, and that just wouldn’t do when ENVE could make their own railings from carbon fiber. Plus, the staircase is so much lighter now. Like most great facilities, a comfortable lounge butts up against the lunch room with mountain bike videos playing on the walls.

A big part of the new facility is increased manufacturing space, but it also means more breathing room for engineering and sales staff. ENVE currently employs six design engineers along with a few manufacturing engineers, and it was clear that they were enjoying the newfound space.

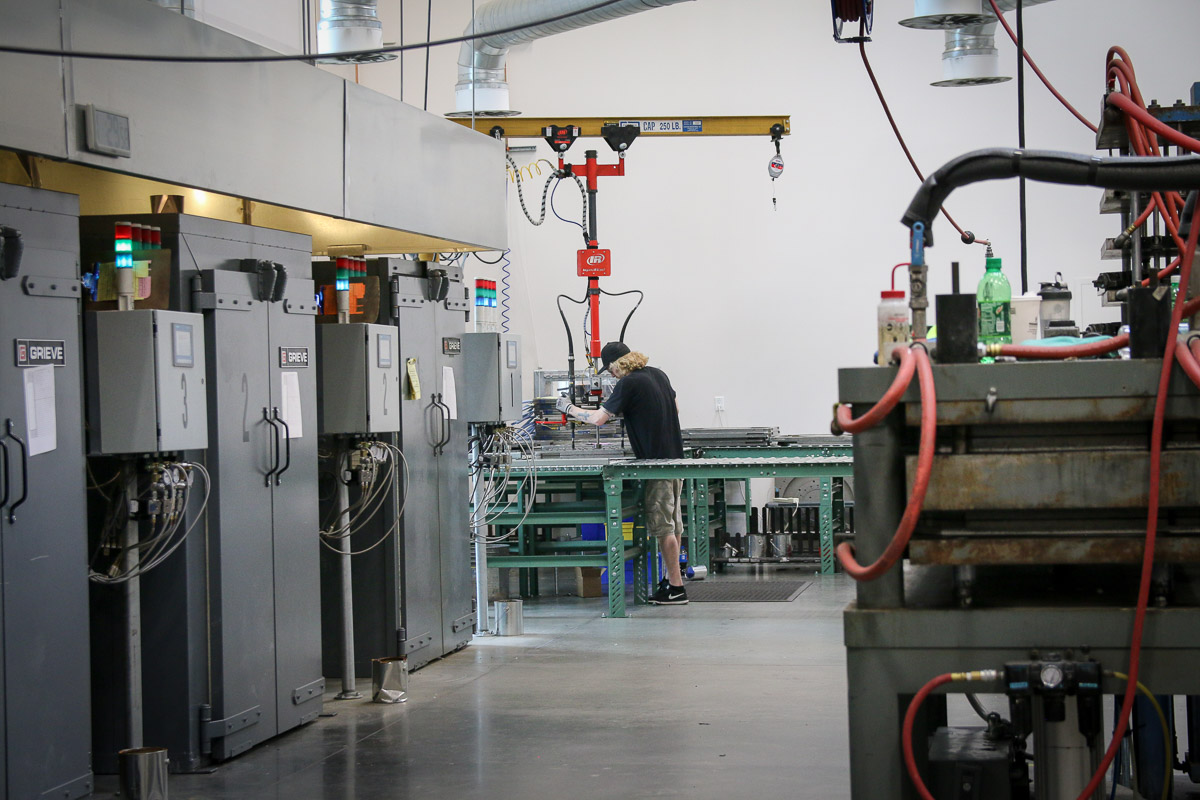

Moving into the manufacturing area, ENVE has a full machine shop to make anything from fixtures to molds for each rim. Most of the molds ENVE uses are aluminum with an anodized surface for increased durability. Steel molds are more durable in the long run, but they’re super heavy and more expensive to make. ENVE’s aluminum molds are lighter, easier to manufacture, but have about a 500 wheel lifespan. ENVE is capable of going from a model to a finished mold in 24 hours and laying up their first part, whereas they claim that lead time is typically 6-8 weeks. With over 500 molds in house, ENVE has gone from 4 to 54 rims in their catalog.

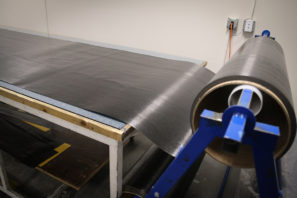

As ENVE’s Director of Marketing and Product Management Jake Pantone invites us into their cold storage for carbon fiber, you can enter the refrigerator on one side, and exit directly into their Class 10,000 clean room on the other side. Maintained at a strict 36 percent humidity and 68°f, the conditions are ideal for keeping the raw carbon pliable but not sticky. Using mostly Mitsubishi fiber with a Newport resin system, while the Japanes carbon fiber is similar to what many other companies use, ENVE says the key is the resin system which is from a company in Newport Beach. Fiber is stored in the fridge until it’s ready to use, and then typically it sees a 24 hour out time for consistency.

Moving from a batch system, ENVE now uses a single piece flow methodology which has allowed more flexibility in the manufacturing process. Every operator can now build every wheel, which are made up of pieces of carbon that are cut by hand from the large rolls, then cut with an automated plotter. Every piece of carbon is labeled with a control number, and every rim since 2009 is tracked in a database which includes every piece that was part of the layup. The long tray on the table above is filled with all the pieces to build a rim, with the exception of a few additional pieces for the rim channel.

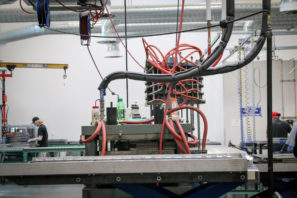

Once the pieces of carbon are laid up into the molds, the two halves are connected with a twin spindle connector borrowed from the auto industry which speeds up the process and keeps even tension on both sides. The molds are then loaded into the ovens where an internal bladder filled with nitrogen compacts the carbon from the inside. There are also a few 250 ton presses for compression molding of stems and other parts. Once the carbon is set, the molds are loaded into chill presses to cool them down so they can be opened.

Out of the mold, rims head for the sanding and drilling area, where one of ENVE’s longest standing employees watches over the process. The story is that years ago, Emiliano was promised a clean environment for what is traditionally very dirty work of sanding and drilling carbon fiber. With the new facility, that’s finally a reality as this area was immaculate considering the operations involved. Now mostly automated, the large yellow robot picks up rims and takes them through numerous sanding operations to remove any flash from the molding process. Then a modified lacing robot drills holes in the rim* with laser precision. *ENVE notes that their spoke holes are molded into every rim they make as well as a conical seat for the nipple, the drilling process shown above is punching a hole through the tire bed to give access to the spoke hole for wheel building.

A number of finishing processes like decals and anodizing are done off site, but painting is still done in house. This isn’t your average paint booth though, as ENVE wanted a finish that doesn’t require sanding after the final coat. After hiring Serotta’s old painter, a new downdraft paint booth was installed, and PPG qualified water based paint is applied with a solvent clear coat after each hub or stem is sanded by hand to remove any flash. ENVE mentioned that a bit part of this process was ensuring that the factory including the paint process would meet environmental standards for the next 20 years.

Completed rims head to this house made storage facility that allows ENVE to practice first in – first out. The racks have storage for 10,000 rims but they say rarely is it even close to full before they get built into complete wheels or sent out the door as rim only.

ENVE also still produces carbon tubing for small frame builders. A number of mandrels and tools are shown here.

We weren’t able to snap any photos, but ENVE also has a complete R&D facility within the new building which is capable of completing most of the entire process without leaving the room. They use this area for finalizing layup, tooling, and fit, form, function, and ride testing of new prototypes before they enter production.

Rims are built into wheels in the center of the building with a lacing machine and tensioning robot getting things rolling. Every wheel is finished and brought up to final tension by a human, as well as trued and prestressed. The deepest rims are still laced by hand since they won’t fit in the machine. From there it’s straight from the stand, to the decal application, to the box.

Wheels are boxed up, then placed in towering racks before shipping to dealers, OEMs, and customers.

Like any quality manufacturer, ENVE has an advanced testing facility capable of running every standard industry test along with a few of their own. When testing, a single rim has to go through every test in the lab which includes a max tension “dummy” build, lateral stiffness testing, max. load to failure, brake track testing, max. inflation (1.5x tire psi rating) testing, and finally impact testing to break the rim. Then it’s cut into pieces and they pull a spoke through every spoke hole – which requires stronger spokes than what they’re built with. Apparently, the spoke holes can withstand more force than a double butted spoke can. ENVE also tests hubs with 1600 watts through the freehub, as well as general fatigue testing.

Upstairs, above the busy manufacturing floor below, a selection of the EDGE/ENVE history was on display. Based on what we saw in Ogden, it won’t be long until ENVE has to make room for more memorabilia when the time comes for their 20th anniversary.