Spotted overnight on Ratio Technology’s Instagram, it seems they are developing a prototype Direct-Mount rear derailleur kit to work with SRAM’s latest UDH dropout/hanger standard. And in true Ratio fashion, it is a straightforward upgrade to old mechanical shifting gear that will likely bring much of the performance of SRAM’s as yet unreleased latest & greatest tech, but at a fraction of the cost for those tinkering with older components…

Updated with a bit more on the 3D-printing & compatibilities…

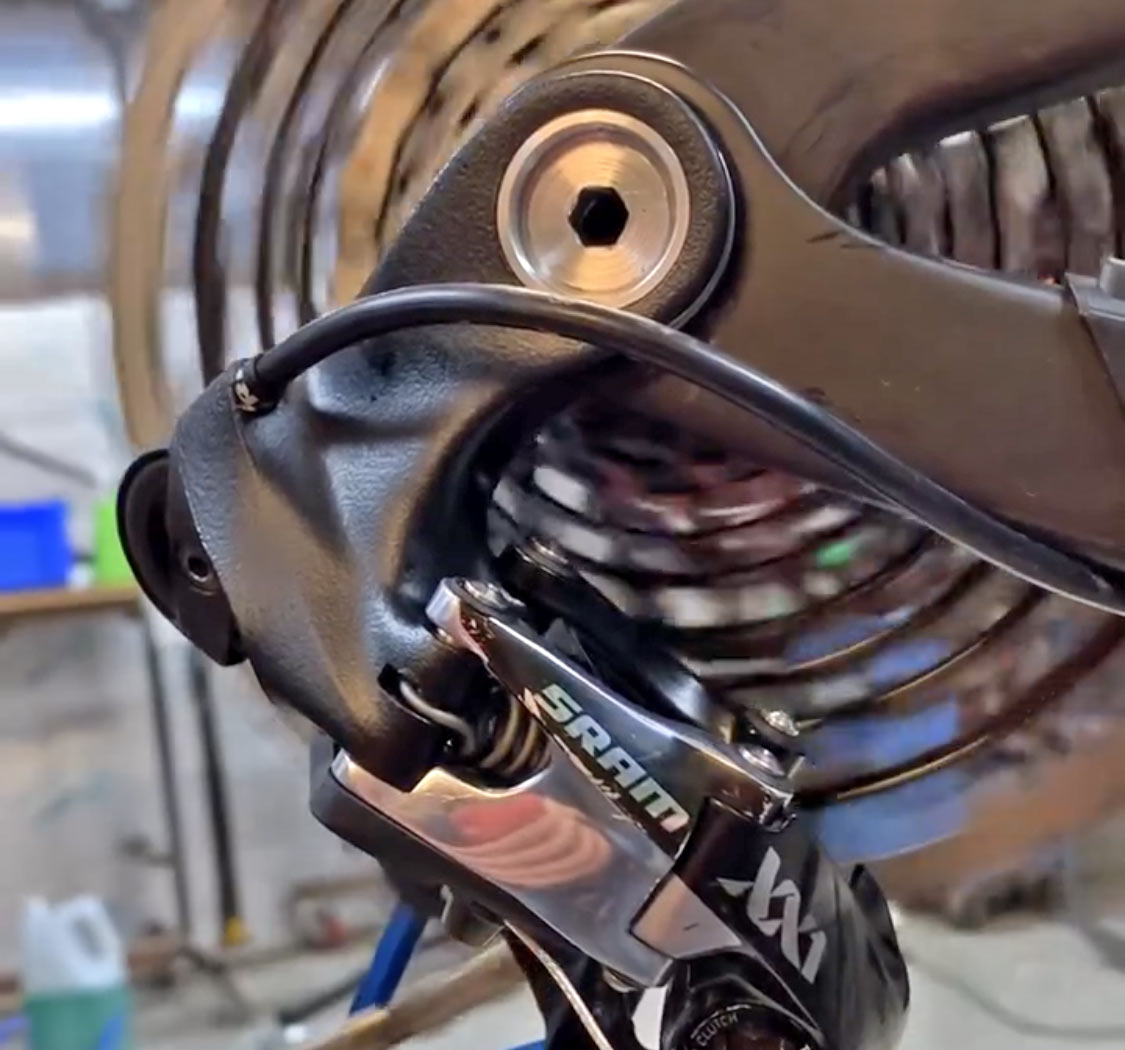

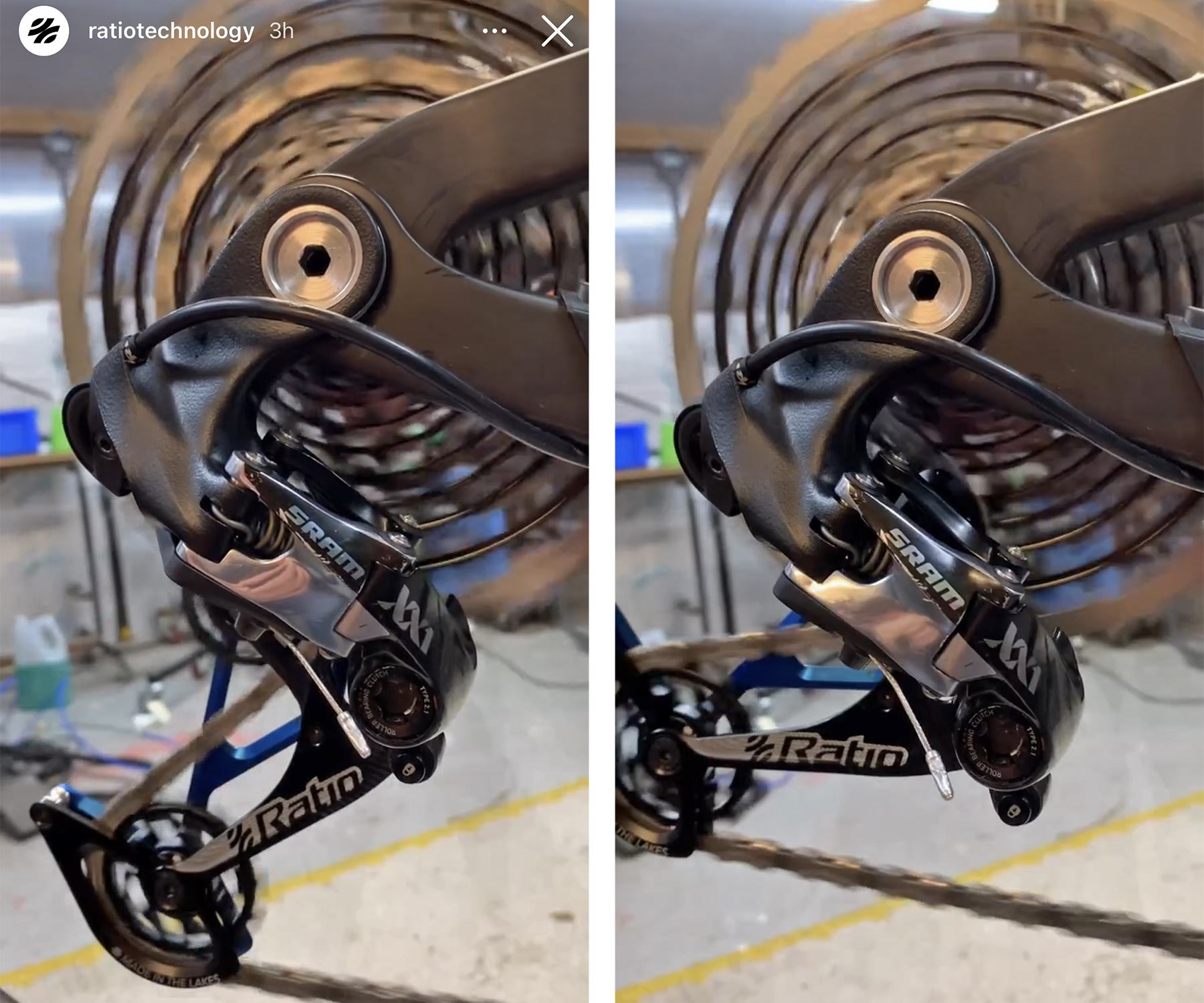

Ratio Direct-Mount XX1 mechanical derailleur prototype

What details we really know about Ratio’s Direct-Mount derailleur prototype still remain thin, but it looks like they’ve once again repurposed some old drivetrain gear to bring modern wide 1×12 gearing upgrades. And with a new direct-mount wireless SRAM XX1 AXS Eagle SL drivetrain rumored to be dropping any day now… perhaps Ratio could even beat the big drivetrain maker to market with a similar, but profoundly more affordable upgrade option…

The Ratio prototype setup started life as a 1 x 11-speed SRAM XX1 Black X-Horizon mechanical rear derailleur which would have been limited to a max 42T cog.

First, the new in-house-machined Ratio 1×12 Wide Cage upgrades the old mountain bike derailleur to 12-speeds and a big Eagle cassette up to 52T – for £90 or ~$80€.

Then, it looks like they have entirely removed the upper B-knuckle – easy enough on this top-tier derailleur from around 2015 since its pivots were already rebuildable. And Ratio swapped in their own – presumably 3D-printed metal – B-knuckle with a direct-mount interface to the UDH-ready dropout.

Update: Interestingly Ratio confirms that this one is actually 3D-printed nylon prototype. It’s apparently strong-enough and stiff-enough as a proof of concept that can in fact shift the gears. But Ratio says they will “be looking into alternative materials before we settle on the best solution.”

That’s it. That’s all we know for now. No word on if, when, or how much the B-knuckle would cost, or what existing derailleurs would be compatible.

But we’ve reached out for a comment, and will certainly be closely watching Ratio’s social media feeds for further teases and more concrete details.

View this post on Instagram

Lots More Updates: Ratio now confirms that the direct-mount upgrade is “still early days” so things like pricing and final delivery timeline aren’t nailed down yet. They say the replacement is pretty DIY for someone capable, but the right tools make it much easier. So… they’re “hoping to be able to supply a kit with custom tools to help with the replacement and with future servicing of the derailleur” and will be able to offer replacement parts down the road – remember there’s no more sacrificial hanger to protect against crash damage.

Oh, and watch them hit that nylon prototype with a hammer above!

One of the most interesting comment from Ratio is this, “Our aim is for compatibility with the full SRAM 1x range“. That’s a pretty broad range for compatibility’s sake, and furthers their idea of democratizing wide-range modern drivetrains, quite a bit more.

They also recognize that not everyone loves the concept of removing the weak link derailleur hanger, and they say, “it’s fair to say we’re not in one camp or another yet, until we’ve completed our testing. However, the benefits to making derailleur mounting more accurate and repeatable are clear, as long as they don’t compromise other aspects of the design“. Ratio sees a ton of drivetrain troubleshooting that’s often fixed by straightening a hanger. Wrapping up with this, “If we do go ahead, we want our company and our products to be responsible. We’ll design everything to be as easily and inexpensively replaceable as possible.”

That’s certainly a refreshing perspective in a time of seemingly disposable products.