Stealing the headlines today is Trek’s all-new Fuel EXe. It is a 140mm eMTB with the $12,999.99 XTR-equipped 9.9 model weighing a claimed 17.47 kg (38.51 lb) in a size medium. It rocks a 360 Wh battery powering a mid-drive motor with a peak power of 300 Watts and a maximum torque of 50 Nm. Those stats align it with other lightweight mid-level assist eMTBs on the market such as the Orbea Rise and the Turbo Levo SL. However, unlike the aforementioned, the new Fuel EXe doesn’t even look like an eBike, at least not upon first glance of the drive-side, anyway.

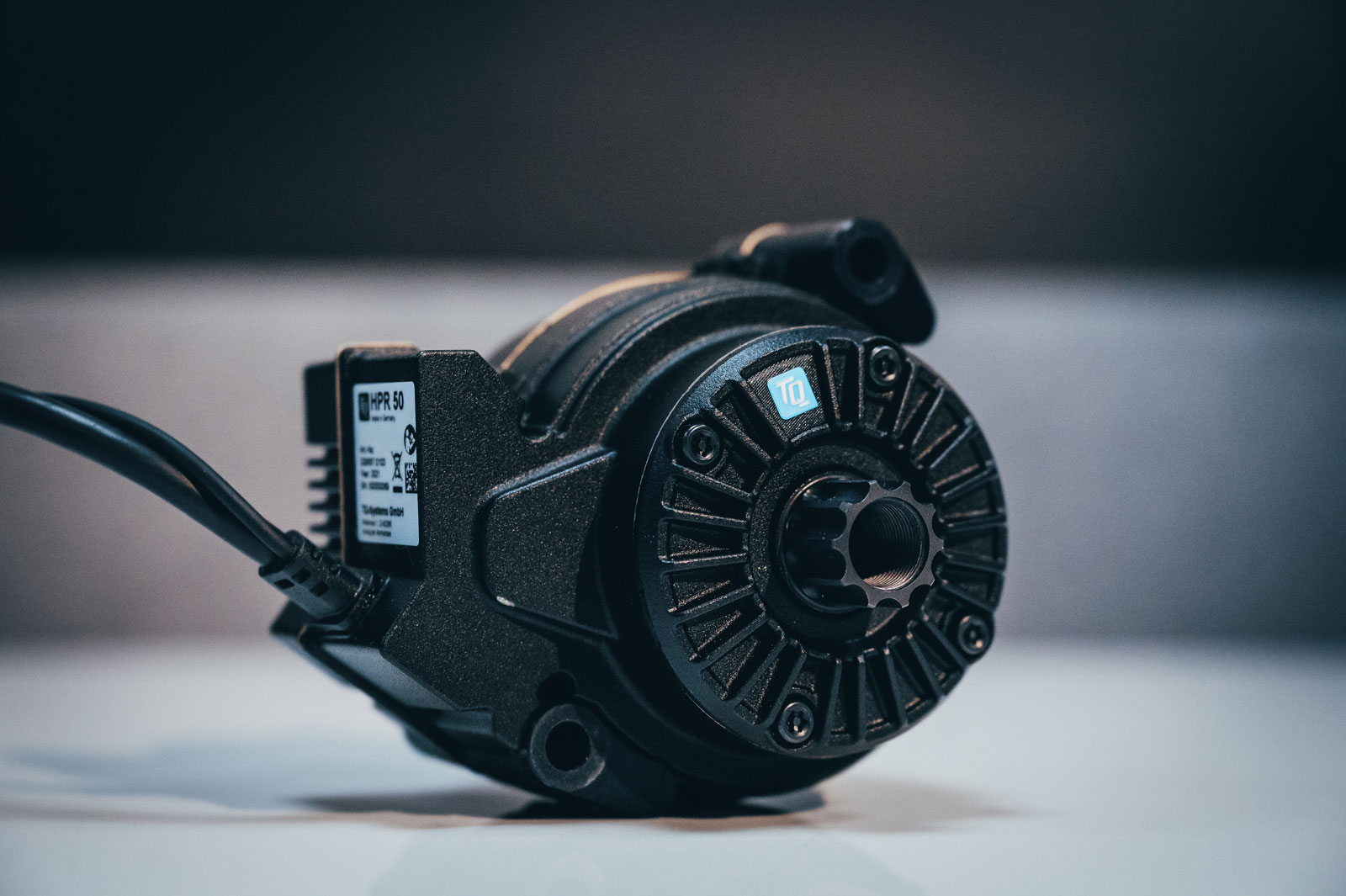

That’s because the Trek Fuel EXe runs a new eBike motor from a little-known electrical engineering company based in Bavaria, Germany. That company is TQ, and their new eBike motor is the TQ-HPR50. Together with its 360 Wh battery, it weighs just 3.9 kg, and boasts a torque density of 82Nm/dm³; apparently the highest torque density of any eBike motor on the market.

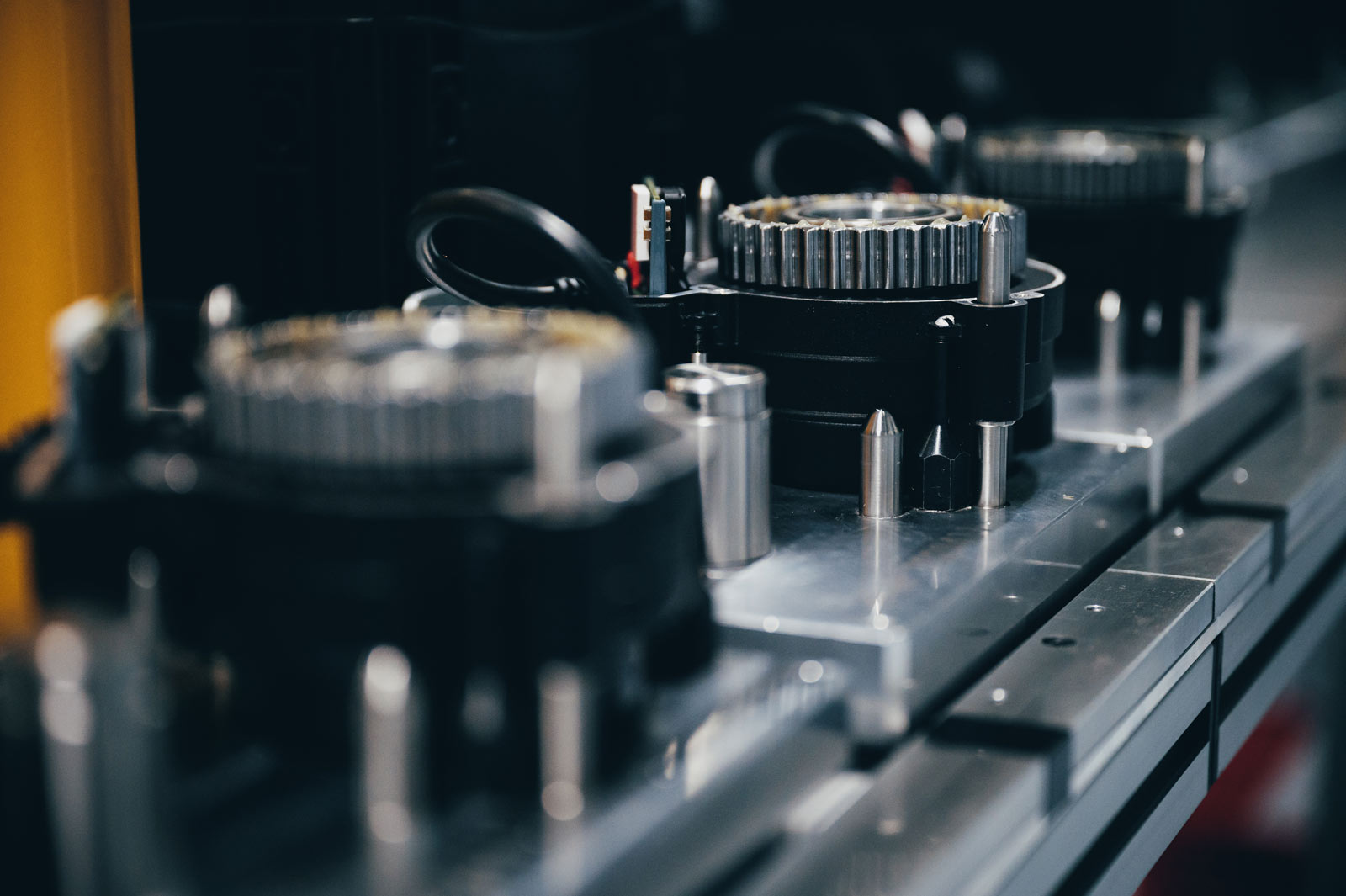

The TQ-HPR50 motor is so different to the common eBike motors that we saw fit to give you guys an in-depth look at its Harmonic Pin Ring Transmission, and a breakdown of all the ways in which it is seemingly better than anything that has come before it. It launches with the Trek Fuel EXe, but we expect other eBikes to be sporting it in the future.

The TQ-HPR50: A new lightweight eBike Motor

The TQ-HPR50 delivers a peak power of 300 Watts and a maximum torque of 50Nm, as compared to the 500 Watts and 85Nm/90Nm torque offered by the full-powered eBike motors out there such as the Shimano EP8 and Bosch Performance Line CX.

Compact with narrow q-factor

The TQ-HPR50 motor has one of the smallest footprints of any eBike motor on the market. It doesn’t seem quite as small as the Fazua Ride 50 Evation Motor, but like that one, the TQ-HPR50 is small enough to fit directly behind the chainring. From the drive-side of the Fuel EXe, you can’t even tell there’s a motor in there; it’s only when you look to the non-drive side that you see any evidence of that.

In fact, it is so compact that it boasts a Q-Factor of just 135mm. Putting that into context; the Q-Factor of the Shimano EP8 motor on the Orbea Rise is 177mm, while the Turbo Levo SL 1.1 motor has a Q-Factor of 181mm. Trek spec E*thirteen E*spec cranks across all models for now, so the bike’s Q-Factor is only millimeters narrower than that of the Trek Rail. However, as and when narrower Q-Factor cranks become available, Trek will be free to run a much narrower Q-Factor than most other eBikes, making for a bike that, again, will feel more natural to pedal.

High energy density

The motor itself weighs 1.85 kg, while the 360 Wh battery weighs a claimed 1.83 kg. TQ tell us that is the highest energy density of any eBike battery on the market.

Not only is the TQ-HPR50 motor tiny, it is also packs the highest torque density of any eBike motor on the market today, while also being quieter than most of them, too.

Details from TQ

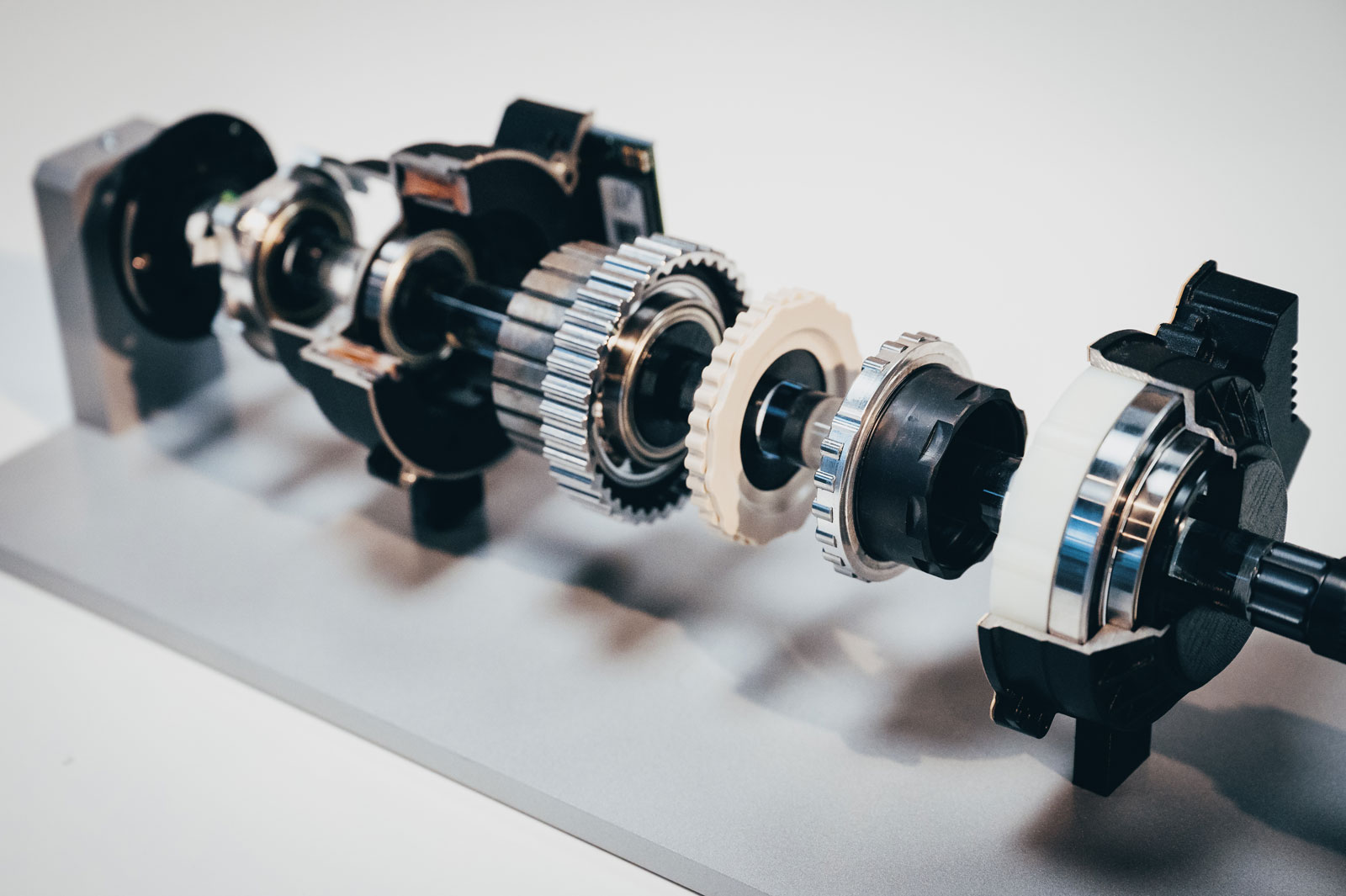

So, how exactly do TQ achieve all that inside a tiny footprint? The answer lies in their patented Harmonic Pin Ring Technology.

We hopped on a call with TQ Product Manager, Daniel Theil, to learn more about the TQ-HPR50 motor and how it differs to the higher power eMTB motors we’re all a little more familiar with. He has a background in mechanical engineering, and has been working on the TQ-HPR50 since the beginning. Here’s what we learned.

Central to any eBike motor is the mechanism it relies upon to achieve the appropriate reduction ratio. What’s that when it’s at home? Well, every eBike motor has an electric motor that spins at a much higher RPM than the rider’s pedaling cadence. The reduction ratio refers to that ratio between the RPM of the electric motor, and the RPM of the rider pedaling. What makes the TQ-HPR50 stand out is the mechanism it relies upon to achieve that reduction ratio. That’s where the Harmonic Pin Ring Technology comes in.

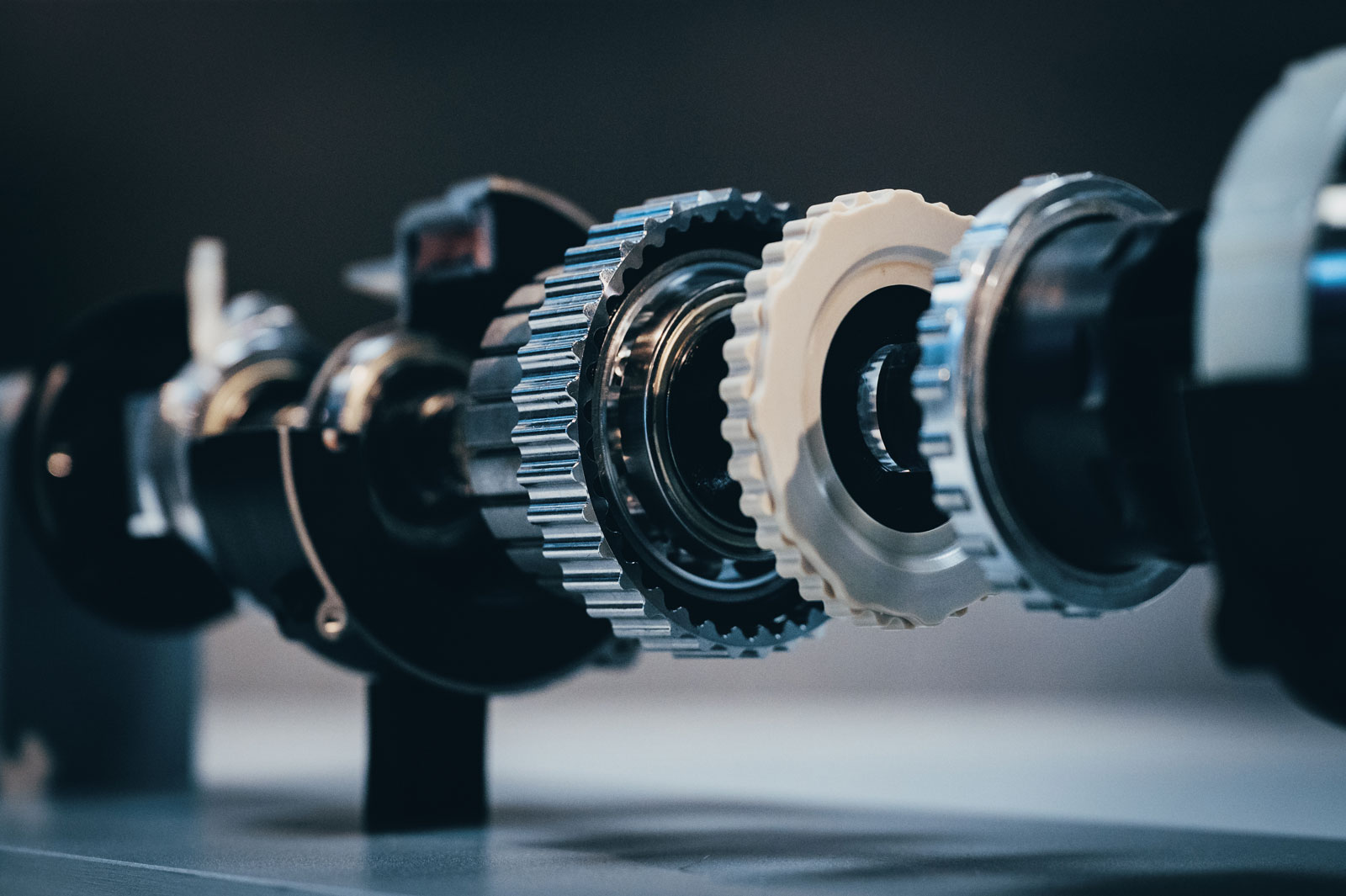

Most other eBike motors on the market use planetary cogs (save for the Brose offering that uses a belt drive) to achieve the desired reduction ratio. They use several steps of cogs that engage with one another to reach it. Meanwhile, the Harmonic Ping Ring requires just one step, and that is executed by the how an inner spline ring interfaces with and drives an outer spline ring.

The smaller inner spline has fewer teeth than the outer circular spline. It is not simply the difference in the number of teeth that achieves the reduction ratio, but also the difference in how fast each spline is spinning. Yes, it’s complicated. We aren’t mechanical engineers, so we’ll leave it at that. This animation sheds some light on how those splines work together to achieve the desired reduction ratio.

Because the TQ-HPR50 can achieve the required reduction ratio in one step, without the use of lots of moving parts, the whole motor can be constructed concentric to the bottom bracket. It’s neat, right?

All about that reduction ratio (for silence)

There’s more.

The reduction ratio of the TQ-HPR50 motor is 17.5, much lower than the reduction ratio used by other commercially available eMTB motors. On the Levo SL 1.1 motor, this is around 50. So on that bike, the electric motor spins 50 times as fast as the rider’s pedaling cadence. At the same rider cadence, the electric motor inside the SL 1.1 is spinning 3x faster than the electric motor inside the TQ-HPR50 would be. Despite these marked differences, the TQ-HPR50 motor is still optimized for a rider cadence of 60-80 RPM.

Why did TQ opt for such a low reduction ratio? In the pursuit of silence, actually. Now, they aren’t claiming their motor is completely silent, but they are claiming it is a lot quieter than the SL 1.1, and the motors seen on popular full-assist e-mountain bikes.

Another benefit of that low reduction ratio is that the motor can fully support a rider cadence of up to 140 RPM. Obviously, no one actually pedals that fast over any measurable distance. But, Daniel tells us that their data from testing showed them that, on some super technical steep climbs, riders were putting in half pedal strokes that approached that cadence.

For those familiar with traditional Harmonic Drive Systems that are used in aerospace, medical and robotics applications, the TQ-HPR50 uses a mechanism that is actually quite different to those. While the TQ-HPR50 does share the same high precision and direct engagement of traditional Harmonic Drive Systems, it does not share their low efficiency.

Those feature an inner spline that flexes in order to push the teeth into the outer circular spline. It is the flexing of that inner spline where energy is lost. With eBikes being a battery-powered application, this lack of efficiency simply isn’t workable. The TQ-HPR50 motor overcomes that issue with use of an inner spline actuator that sits offset of center, so no parts are required to flex. Daniel tells us it is this mechanism, as well as TQ’s special tooth profile, that really improves the HPR50’s efficiency over traditional Harmonic Drive Systems.

No battery required

Back to (e)bikes.

Daniel Theil tells us that, if you do want to ride the Fuel EXe (or any future bike that may have the TQ-HPR50 motor) in its analogue configuration, i.e., without the battery, it will pedal much like a regular trail bike. That’s thanks to its drag-free internals and integrated freewheel. Of course, all eBike motors have that integrated freewheel that decouples the axle from the gearing, but in some cases there are still some parts moving inside the motor even when the system is switched off. That unnecessary rotating mass and friction creates drag, and means that more of the precious Watts you are producing at the pedals are lost by the time your efforts are translated to the chainring.

The TQ-HPR50 motor is different in that the simplicity of the Harmonic Pin Ring Transmission means the integrated freewheel completely decouples the axle from all the other motor internals, resulting in virtually no drag. The only drag in the TQ system comes from the seals (2-3 Watts); they could be removed of course to deliver zero drag, but they are obviously extremely important in keeping water and contaminants out of the transmission.

Is it waterproof?

In fact, TQ went above and beyond with the waterproof rating of their HPR50 motor. Most eBike motors have a waterproof rating up to IP64 – that means they are protected from total dust ingress, and protected from water spray from any direction. The TQ motor has a rating of IP67, which means you could actually submerge the motor up to a depth of 1 meter for up to 30 minutes. The Levo SL 1.1 motor boasts that same IP rating, too.

Obviously, I hope no rider will ever have that misfortune, but that IP rating does sound rather appealing to this rider who is familiar with the deluges of Scottish winter. Also, can’t help but be reminded of Danny MacAskill’s watery excursion in “Wee Day Out”. The batteries also boast the IP Rating of 67, while the display and the remote get a rating of 66, the rating for “strong hose water”.

Tyler has a review of the new Trek Fuel EXe in the works, so you’ll not have to wait too long for details on how the TQ-HPR50 motor actually rides. In the meantime, check out our launch coverage of the EXe here, including full details on geometry, model specs, pricing and availability.

We’re at Eurobike this week keeping an eye out for any other new eBikes rocking the TQ-HPR50 motor. Stay tuned.