Fox Factory has filed a patent titled “Methods And Apparatus For Lubricating Suspension Components” detailing the use of bushing-housed ball bearings coupled to a self-lubrication system. The patent gives us some insight into how Fox’s long-travel mountain bike forks such as the 36, 38, and 40 may evolve in the future, with the inventions described working to reduce binding at ever-slacker head angles, while also continuously lubricating the wiper seals during use.

Tucked away inside that very same patent document is a description of a coil sprung fork, travel-adjustable over its full 80-125mm range, indicating the possibility of a new XC/Downcountry fork on the Horizon from Fox, or more likely their sister-brand, Marzocchi.

Images adapted by Cory Benson

Fox Self-Lubricating Fork

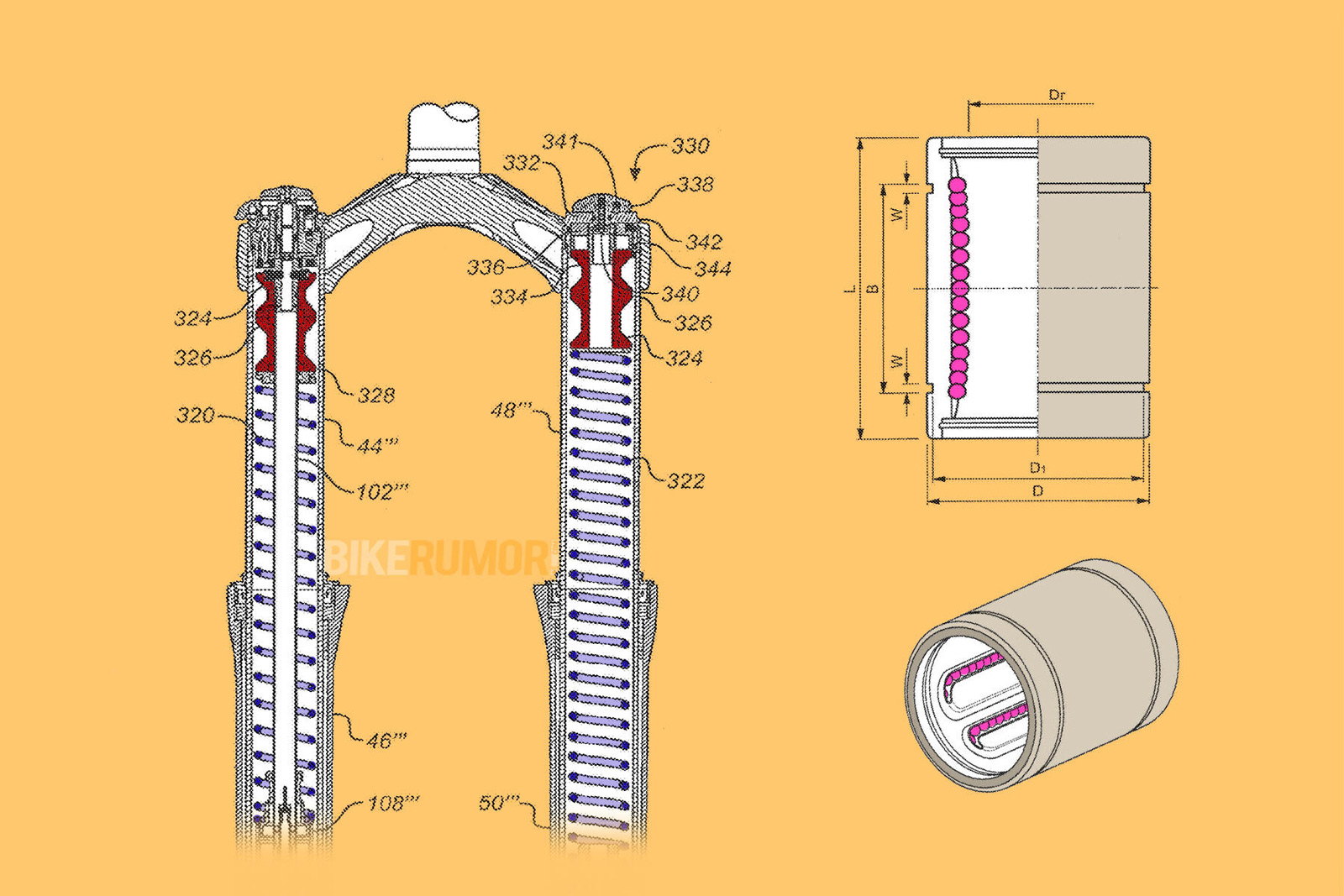

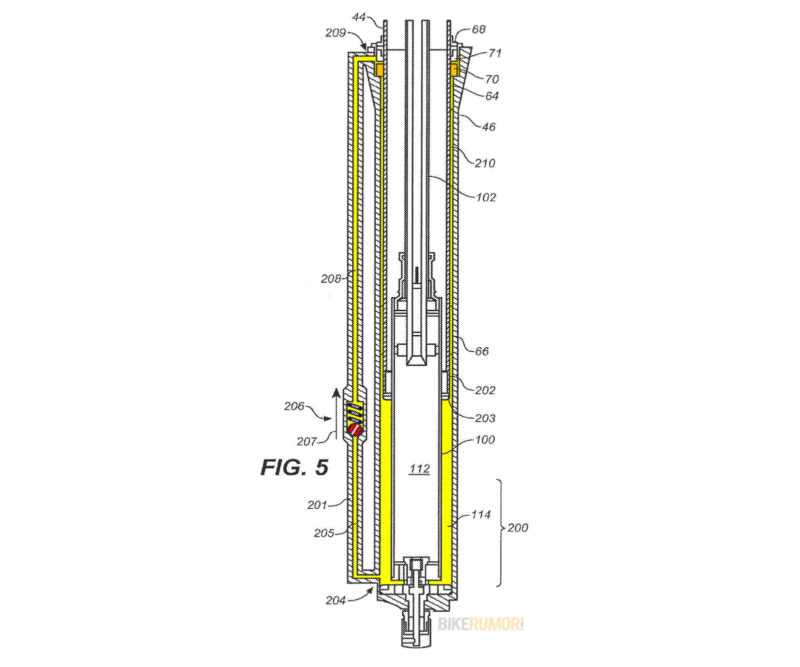

This latest patent from Fox (US 11566682 B2) describes what we imagine to be the inner workings of the lower leg channels that can be seen on the Fox 38 suspension fork. Basically, lubrication oil sits in a reservoir situated in the lower leg, and that oil is forced into a “fluid conduit”, or channel, when the fork is pushed into compression. The channel sends that lubrication oil up the leg to the wiper seal region, dropping it back into, or nearby, the foam ring.

This self-lubricating system works to ensure the foam ring is always saturated with oil, such that the wiper seal and the fork’s stanchions remain lubricated during use. That would help keep your suspension fork feeling smooth off the top of its travel. A check valve featuring a spring-backed ball bearing, pictured around half way up the fluid conduit, ensures that oil can only travel in one direction through the channel.

The patent then describes a bushing within the lower leg that features cup, lip, or chevron seals that allow lubricating oil to travel back down into the reservoir. The system is designed to continually cycle the oil up to the foam rings during normal use of the fork.

Fox Fork Sliding on Massive Ball-Bearing Bushings

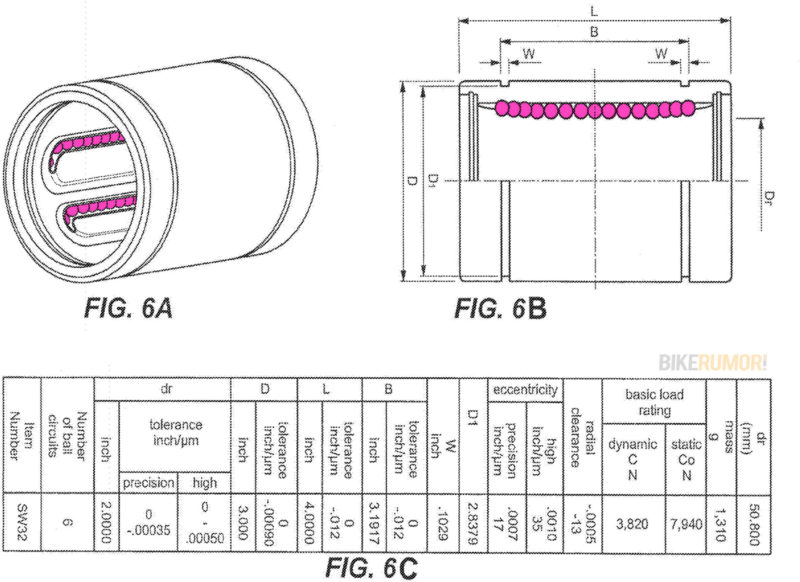

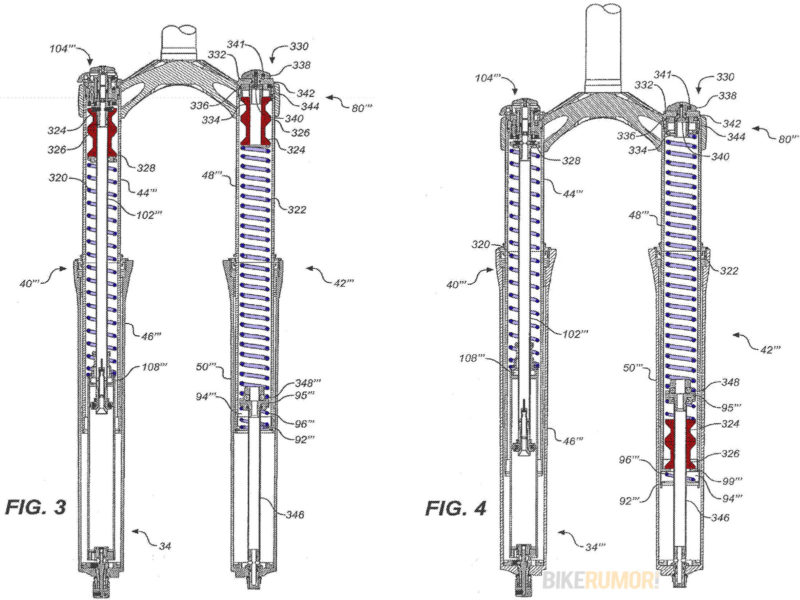

What’s maybe most interesting about this Fox patent is the embodiment that includes use of ball bearing bushings. While traditional bushings can be described as solid, low-friction rings… these bushings described here use “linear motion bearings”.

The idea here is to eliminate the undesirable effects of bushing binding. Basically, when a fork compresses, it is subject not only to forces operating directly through the telescopic plane, but also forces that are anywhere between parallel and perpendicular to that. Such forces can cause the bushing to stick or bind, which can prevent the fork from operating smoothly. These linear motion bearings are described as up to 6 circuits of ball bearings located on the inside surface of the bushing, which should allow the fork to telescope more freely with reduced friction induced by side-loading.

Here’s how the patent document describes it:

“In use, a suspension fork is typically positioned in a bicycle or motorcycle at a rake angle. More specifically, the steering tube (and hence the fork) is attached to the vehicle at an angle from the vertical (e.g. rake), as opposed to absolute vertical, to enable improved vehicle handling. An artifact of that angle is that the weight of the vehicle (and associated impulse load due to impact) bearing on the front wheel imparts not only compressive but also bending loads into the front fork and its legs. Such bending loads increase the relative sliding resistance between, for example, the upper leg tube and the lower leg tube (by increasing the normal/radial load on, for example a side of the bushing). An advantage of linear motion bearings is decreased apparent friction between [the] upper leg tube and [the] lower leg tube due to decreased friction between the upper leg tube and the interior of the bushing. Such decreased friction allows the suspension to move more freely, and better absorb shock despite the tube side loading incident to the rake angle”.

Sounds sensible, right?

Now, take a look at the tables beside the drawings of the bushings. That suggests that such a bushing would be 3.0″ in diameter. That’s a lot wider than the lower legs of forks that are commonly in use today. At least on bicycles, anyway. The last time we saw a fork made for mountain biking that was anywhere near that chunky? The Cannondale Lefty Super Max Carbon PBR, perhaps. That single-sided fork used a hybrid needle bearing system that, similarly, claimed to result in a smoother fork than traditional designs.

Likely, the dimensions of these ball bearing bushings would need to come down a fair bit before they could be successfully implemented. Still, if Fox were to use them in place of a plastic bush, we could see fork lowers grow considerably, with overall fork weight heavily impacted, too. That said, the rider of a 30kg eMTB may not be too bothered about the added weight, especially if performance is significantly enhanced.

Another explanation is that Fox is hiding technology intended for a motorcycle inside a patent that looks to be focused on bicycles. Who knows?

Rightly so, you may wonder about the durability of such a design. The design from Fox doesn’t ignore this: “a surface hardness treatment is applied to an exterior of the fork leg engaging such a ball type bearing to reduce the effect of high localized bearing stress on contacted portions of the fork leg”.

In one embodiment, the Fork patent describes the use of the linear motion bearings in combination with the self-lubricating system. Therein, the bushings also feature gaps positioned periodically around their circumference to allow fluid to flow back downwards into the reservoir.

Is a Short-Travel Coil-Sprung Marzocchi Fork with Adjustable Travel on the Horizon?

Elsewhere inside the latest patent from Fox (US 11566682 B2) is the description of a travel-adjustable coil-sprung fork. Travel can be adjusted over a range of 80mm to 125mm by positioning one or two spacers either above or below the coil spring, much like we see on the Marzocchi Bomber Z1. One of those spacers is 25mm tall, while the other is 20mm tall, indicating that possible travel lengths are 80mm, 100mm, and 125mm. With small travel numbers, such a fork would likely be aimed at XC or, given that the weight is unlikely to be competitively low, Downcountry.

For now, it’s a “no comment” from Fox on all of the above.

They did admit to some new, longer lightweight dropper posts today, though…