Since their beginnings in 2007, Lezyne has always been about design. Even the name Lezyne is supposed to bring the word design to mind (which is why they rhyme, it’s not pronounced le-zeen). Lezyne is the brain child of Micki Kozuschek, a former professional triathlete, who started on the business side of the bike industry with Maxcycles. From there, Micki moved to the US and founded a company you have have heard of, called Truvativ which as we know, was later sold to SRAM in 2004. Three years later, Micki was back with a new project, Lezyne – Engineered Design.

Based in the US with a headquarters in San Luis Obispo, CA, Lezyne doesn’t really see themselves as a US company necessarily, but an international company with a quickly growing facility in Taichung, Taiwan. On our recent trip to Taiwan for the Taipei show, we had a chance to ride the amazing High Speed Rail down to the manufacturing heart of the bicycle industry and to check out Lezyne’s facility first hand.

If you time your visit right, you may find yourself with a cappuccino made by the one and only, Cedric Gracia…

In the Taichung facility alone, Lezyne typically employs around 120-150 employees depending on the season. This is broken down to about 50 employees in office with sales and shipping on one side, purchasing in middle, and R&D on the other. Impressively, nearly everyone speaks English except for purchasing since they are mostly communicating with local suppliers and don’t really need it.

The English skills come in handy since R&D has to communicate with the US frequently, typically having a Skype call every day at 8:30 in the morning which works out to 5:30 PM in California. Both US and Taiwan offices share design duties with similar R&D departments in Taiwan and the US. Due to their proximity to the manufacturing, the Taiwan R&D office also overlooks production and testing.

The beautiful office space also acts as home to three meeting rooms (one doubles as demo room), the finance, accounting, and HR departments, and Micki’s personal Taiwanese office. All of the furniture has been imported to the Taiwan office so that the US and Taiwan buildings are the exact same. That makes it so when employees have to travel between offices, it’s just like being at home.

That ethos extends right down to the coffee machine which is a good thing – caffeine is very important when it comes to jet lag. It also makes it so that Cedric can pull you a shot when he’s in town. Not bad, eh?

Numerous pumps sit adjacent to desks in the R&D department. Color samples?

You may notice while roaming the halls that the building has a common art work theme, with wall art representing years of designs. Posters hung on the wall show different sponsored athletes and shows the progress of Lezyne’s parts leading up to 2014 which was year 7 of Lezyne’s history. Started in 2007, Lezyne is currently working on year 8 product.

Walk out of the automatic, frosted glass doors of the second floor offices and you are face to face with the warehouse and assembly floor. Lezyne is very proud of their assembly facility and they should be – as it is one of the few factory floors in Taiwan that is fully air conditioned. Due to the extremely hot and humid Taiwanese summers, Lezyne provides their assembly workers with an air conditioned work space to keep them happy and comfortable. Believe it or not, insulation really isn’t a thing in Taiwan so it had to be imported for the construction so the room is as energy efficient as possible.

Something you don’t see everyday – R&D, new product development, and initial prototyping is done in this room guarded by a fingerprint scanner. Very few employees have access to the R&D room, and photos were not allowed since copying in Asia is so common. Due to the amount of vendors, and visitors coming in and out of the building, advanced development is done under close guard and accessible only by fingerprint recognition.

Starting at the front of the building is a holding area for parts form external vendors. Once they are delivered, all parts will stay here until they pass the initial QC check, with complete quality control testing done on all parts.

Next to the R&D room is a separate room for QC and a testing facility. Parts are pulled from shipments and brought into the QC room which is equipped with an arsenal of measurement devices like an optical comparator, hardness tester, and battery testers for complete charge and discharge ratings. Lezyne rates batteries for not only amp hours, but watt hours as well, and if batteries don’t meet standards they are rejected to the manufacturer. Once QC checks have been completed, parts are moved from QC to counting and sorting, then moved on to the shelves for regular manufacturing.

Lezyne was just installing their second 3D printer, which like the office is an exact copy of the one in the US. Lezyne initially uses the 3D printer to come up with the basic form, then moves to CNC samples, then to the pilot, and eventually into production.

Parts are put on the shelves for very short periods of time, with most parts being turned every 15 days as 2 containers ship out in the same time frame. This is where the impressive organization pays off. When they are ready for assembly, parts are pulled from the temporary storage to the assembly room with all parts moving from front to back.

Lezyne utilizes a flexible manufacturing style with the same workers performing many different tasks. You may see the same group of employees assembling packaging, assembling lights, and more. About 40% of their workers have been with Lezyne for more than 4 years, which according to Lezyne is rare for the manufacturing world. The company attributes this to the desirable working conditions, and company perks like provided lunches and dinner if they have to work overtime.

Above, employees are testing waterproofness with a vacuum tester. Each light is put into the fixture, a vacuum is pulled and it is either approved, reworked, or rejected. This is a prime example of production quality control, while the earlier example was incoming quality control. Further testing includes 100% function testing for lights, and voltage is measured for every battery before placing it in a light.

Even though most of the manufacturing is flexible, the floor pump line runs 5 days a week the whole year, and never changes. Pumps start with the base, then the barrel is installed. Grease is applied with custom grease gun – similar tools are found throughout production to limit variability by hand.

Every single floor pump is tested for pressure per stroke and leaks, not once, but twice. Lezyne now has a machine that will test 3 pumps at a time, again to take any variability out of the equation. While not as constant as the floor pump line, the hand pump line sees the same testing.

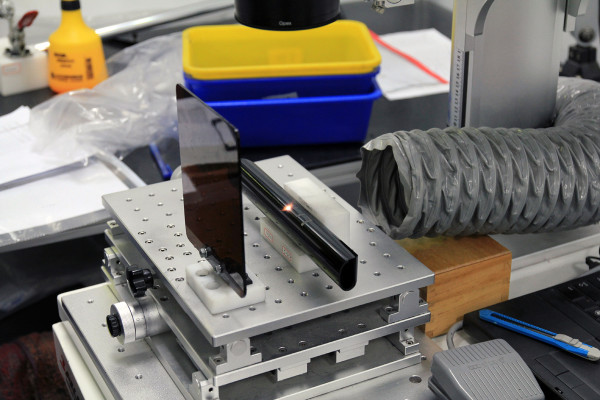

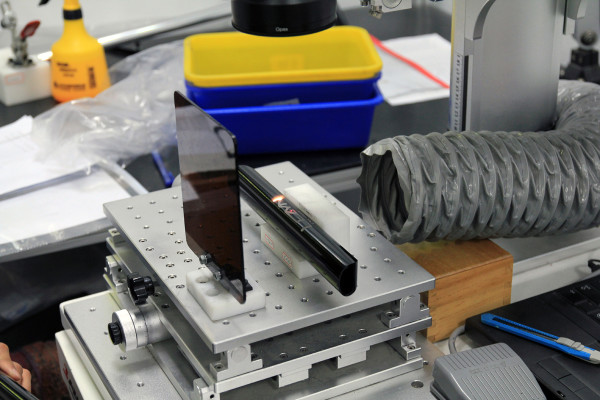

About a year and a half ago, Lezyne moved their laser engraving in house. This allowed them more freedom with the engraving and the ability to do custom product runs for large shops, race teams, or athlete signature models.

Once products reach the boxing point, they head out the other end of the assembly floor to the finished skids warehouse. Products sit here for less than 15 days, while the QC department will come and take finished products off the shelf and perform full function QC check again. If you haven’t caught on by now, QC is big for Lezyne with products being tested before they are assembled, while they are being assembled, and once they are finished and ready for shipping.

Even though most of the physical manufacturing is done off site, Lezyne does some manufacturing in house, with fully automated CNC machines in the back. The machines basically require a single operator as bar stock is inserted in one end, and finished parts come out the other. Lezyne’s intent isn’t to bring all of their manufacturing in house, but to be able to manufacture new parts which much like the fingerprint reader, are able to be shielded from the public until they are ready. Lezyne will be purchasing two more machines in the future, since one operator can run up to 4 machines at a time. Since the machines run 24 hours a day with 3 shifts, having 4 machines total optimizes the cost associated with operation.

Capable of machining numerous parts, the CNC machines were churning out a number of hand pump pieces during our visit.

While touring the Lezyne facility it is easy to start to think that all Taiwanese manufacturing is just as impressively modern, but by simply looking out the back door it’s pretty clear that Lezyne’s Taiwanese factory is fairly unique.

Thanks to Lezyne for all of the hospitality!

If you haven’t seen Lost In Taiwan with Cedric Gracia, this is a great time to do so. Not only does it show a bit of the Lezyne factory, but it also gives a great idea of the local area and culture. And in case you’re wondering – Cedric is every bit as fun to hang out with at the night market as you would expect.