Road Tubeless is an interesting topic, because it came on the scene very fast in 2010, and many thought it would become the next big advance in road bikes through 2011 and 2012. However, as we venture into model year 2015, it still has not taken off in a significant way, with modest or underwhelming offerings from a handful of suppliers that may or may not work together.

So, what’s the hold up?

Well, to put the whole situation into perspective, we need to look at the evolution of mountain bike tubeless tires.

Lets step back to 1999, when the first standardized mountain bike tubeless system, UST, was launched by Mavic. Established over 16 years ago yet really only becoming popular in the last half decade, mountain bike tubeless also took a while to catch on, even though there are arguably a lot more benefits to tubeless tires off road than on. But, despite nearly universal agreement that mountain bikes perform better with tubeless tires, there is still not an agreement what the interface between tire and rim should look like…

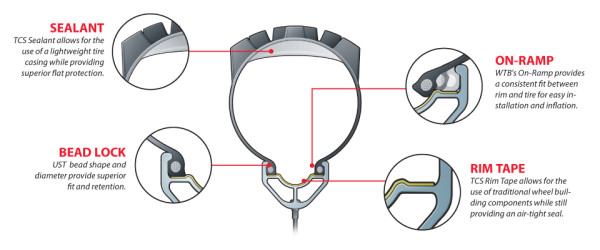

There are essentially three different interfaces on the market today, and only one of them is truly standardized: UST. UST is a standard that defines the bead and rim shapes, and it must be validated by a labratory before it can be labeled as such. This posed problems because UST’s standard does not allow for tape or sealant to be used, instead relying on the rim and tire construction to create a fully closed system. Sealant can be used, but the system must be airtight without it. That meant a solid rim bed (heavier, harder to manufacturer) and an airtight tire carcass with precise bead dimensions (also heavier, and also harder to manufacturer).

The UST system is defined by ETRTO, the European Tire and Rim Technical Organization, who creates standards for of all kinds of rims and tires for cars, motorcycles, tractors, bicycles and more.

Many people see the term ETRTO and think it is a measurement, since it is mostly listed as “ETRTO 559″ when talking about tire or rim sizes. They do specify the bead seat diameters that we commonly know such as 559 (26″), 584 (27.5″) and 622 (29” or 700c), but the organization does a lot more than that. In the case of tubeless, they created a standard that defines a rim valley’s depth-to-width ratio, bead seat diameter, tire bead shape and size, etc. Since they are a standards organization like ISO, there is absolutely no requirement to comply with their standards. That is, until a legal body adopts their standards as the standard to measure against for law, and that is what the EN regulatory body has recently done. That means any wheel on a complete bike that’s sold into the European Union must meet ETRTO standards. Standalone wheels and rims are a separate story, and how strictly this is enforced is up for debate, but those are the rules. And that explains why huge companies like Cannondale will only spec ETRTO-compliant rims on their bike. It’s also why SRAM’s Rise/Roam wheels are all ETRTO compliant, because their volume sales are all as OE parts on complete bikes, and Europe’s a huge market. Keep in mind, the ETRTO and EN law has no basis or requirement in the U.S., but many U.S. companies maintain compliance so their goods can be sold into the massive European market without having to create country-specific specs. ‘Tis a global economy, after all.

Outside of UST are the other two “systems”. We’ll call one of them “NoTubes”, not because they defined a standard, but Stan’s was essentially the pioneer of this method, and it is arguably the most common. With the NoTubes method, the tire was left alone, and the bead seats and valley of the rim were raised up to compensate for any air loss during inflation between the bead and the rim, and then “stretched” the tire into place to hold the seal (this is the tell-tale “ping” of setting up NoTubes-style rims). It required tape to seal the rim’s spoke holes, and non-UST tires need sealant to make them nonporous. Because of this non-standard change, and the ability to use non-tubeless tires, most rims that fall into the NoTubes category are not ETRTO compliant.

The other system we will call “TCS”, mostly because WTB created a system for their own tires and rims that does not fall squarely into either camp. WTB wanted a simple tubeless system using tape and sealant, which avoided expensive tire and rim constructions, yet wanted to be ETRTO compliant. WTB’s TCS can best be explained as similar to UST, except needing tape and sealant, and not using Mavic’s proprietary rim shape. Systems following the NoTubes method typically change the rim, and leave the tire alone, whereas systems following the TCS method typically create a tubeless-style bead, and leave the rim shape to be ETRTO compliant, so these two systems are mutually exclusive. If you’ve ever tried to mount a TCS tire to a Stan’s rim (which WTB strictly warns against), you know that it does not work. And if you go the other way, and mount a normal tire to a TCS rim, you will probably have a hard time getting it to inflate, short of using a very large, powerful air compressor.

This is where the lack of standardization creates confusion, especially now that most companies simply bill their products as “Tubeless Ready”. Let’s take Bontrager’s TLR system for example. Depending on who you talk to, and how you measure it, it could fall into either the NoTubes or TCS camp. Virtually none of the “tubeless ready” tires out there declare which design they used, which can actually create dangerous situations if you combine a tire with a thicker tubeless bead with a rim using a higher-than-ETRTO bead seat. For instance, the new SRAM mountain wheels are billed as tubeless ready but are based on ETRTO standards, so you’d want a tire with a thicker bead (like a WTB TCS tire, or even a UST tire) than than what you’d want to run on a NoTubes style rim.

It can also create potentially dangerous situations if the rim and tire interface allows for the tire bead to slip out of place, burping air or even coming off at the worst possible time.

AREN’T WE TALKING ABOUT “ROAD” TUBELESS HERE?

So, that’s a lot of talk about mountain bike tires in an article about road tubeless, but it highlights some of the concerns that have prevented Road Tubeless from taking over: Confusion, weight and safety. After all, do we really want a standard if it means things will be heavier and more difficult to manufacture?

Here’s where we are today:

In 2006, Hutchinson and Shimano launched a campaign to standardize the road tubeless area, but it didn’t take off because of the increased weight of the system. Almost exactly like UST, it dictated specific rim profiles with a non-pierced bed. That meant more weight and difficult manufacturing. For the tire, it meant a specific bead shape and size and an impermeable casing. This meant extra material, which committed two mortal sins of road tires: added weight and decreased compliance.

This led to a big of stagnation on the idea, until, just like mountain bikes, the smaller innovators saved the weight by moving over to a tape and sealant system, allowing the continued use of the lighter non-tubeless tires.

Following almost exactly the same path as mountain, the next step was for NoTubes to introduce a road tubeless rim with the Alpha 340, which worked with normal tubeless tires, tape and sealant. These rims have been slowly adopted into the road world, but likely because of the deeper attraction to carbon wheel systems, the individual rims have not created the splash on the market that the Arch did for mountain bikes. Only recently have major brands like Reynolds started offering tubeless ready carbon fiber rims.

But those systems rely on tires that aren’t necessarily optimized for their rims, and since not everyone’s licensing the NoTubes design from Stan’s, tire manufacturers have little incentive to change their molds to fit one particular shape of rim until they know which particular rim profile will become the next “standard.”

And as mentioned above, the lack of a standard can create a dangerous situation for the tire and rim interface. On mountain bikes running about 25-35psi, the risks are fairly small. On road bikes however, at 90+ psi, these problems are uncovered much quicker, and with potentially worse results.

Fortunately, we might be slowly moving to a tubeless ready standard we can rely on. Check back next week for Part 2 where we’ll hear from various manufacturers as they answer our questions on industry-wide standards, compatibility and future plans.