What if you didn’t have to choose between flats or clipless pedals? You know, for those times where sketchy conditions might reward the use of flats, followed by long pedaly sections on the same trail? Ferro thinks they are about to have a solution.

Jump past the break to see how the Ferro pedal actually works, plus something else we found up their sleeves…..

Bicycle tech is exploding much to the dismay of purists, but like suspension, dropper posts, tubeless-ready, and e-bikes *eh-hem*, many new technologies become widely accepted and even appreciated. The battle between being clipped in or not is a common debate among friends that has no wrong or right answer. Even pros on the World Enduro circuit may swap their foot lockers for flats on more technical courses. There is no perfect set-up to handle every single condition in a single trail system, but technology has brought us things like dropper posts and this locking suspension to give us our cake while eating it too. So how about having yet another button that’ll let you swap between flats and being clipped in?

A group of students at Michigan Tech belong to what is called The Velovations Bicycle Design Enterprise. They come up with cycling related ideas and collaborate with manufactures on a wide range of things from designing a new bike frame, to improving friction in linkages, and projects involving electrical engineering. (does this make anyone else want to go back to school)? They’ve worked on projects for Niner, SRAM, Saris, Park Tool, Thomson, and many others.

One of their latest projects is the Ferro Pedal that you can turn on and off via a handlebar mounted Bluetooth switch. We’ve recently covered a magnetic pedal from Maglock which allowed you to “tune” the magnetic strength form zero up to 35lbs of force by adding and removing rare earth magnets.

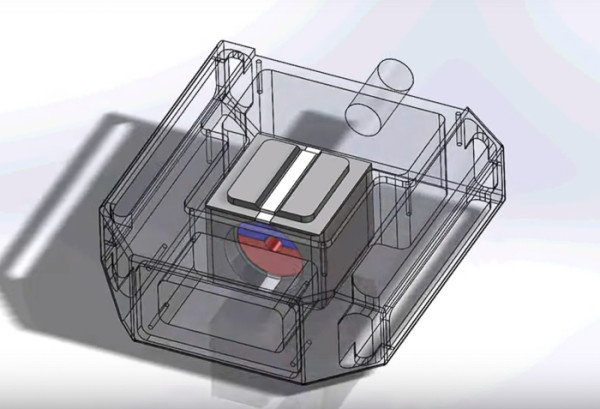

The Ferro Pedal, though still in the early phases, is a pedal that instead of having conventional magnets that produce a constant pull, it uses what are called diametric magnets. Diametric magnets are round or cylindrical shaped, and instead of having the north and south poles on the flat surfaces like a standard magnet, they have them on the rounded sides. The Ferro pedal works by placing the diametric magnet in between two pieces of non-ferrous aluminum that are sandwiched together with a piece of ferrous material separating them. When the actual poles of the magnet face away from the aluminum they won’t charge the aluminum thus not create a magnetic attraction to the ferrous plate/cleat on the shoe. When the diametric magnet is rotated 90° and the poles face the aluminum (putting the poles’ axis in line with the ferrous material separating them), it charges the aluminum creating a strong force that attracts the shoe’s plate/cleat to the aluminum.

Or simply put…. because SCIENCE! (see video to get a better idea on how it works).

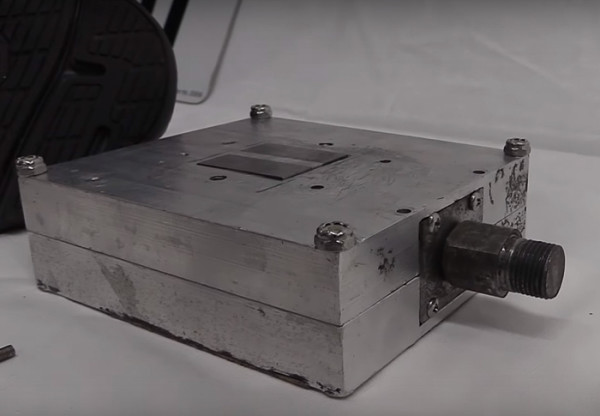

The first prototype was a success functionally, but in addition to reducing the pedal’s size, they want to fine tune the pedal-to-cleat interface so that while actuated you can still “un-clip” similarly to that of a conventional clipless pedal. Based on the results of the first prototype, they expect to get a whopping 70 plus pounds of vertical pull force on the next version. It is hard to determine the battery life of the pedal as reducing the size of pedal also reduces the size the battery but say they’re confident they can get at least 150 cycles out of a single charge. In a worst case scenario, the battery dies, you’ll just be riding on flats the rest of the ride.

Could this be the next dropper/tubeless ready/”anything else that gets criticized before acceptance” product that improves our riding experience?

Totally unrelated but we stumbled across this pic on their site and the caption said they were testing internal pressure sensors…… hmmm.