Nestled in the beautiful Southern California desert, at the foot of a mountain range that hosts some of the areas best mountain biking and road rides is Intense Cycles. The company, which was founded nearly twenty five years ago, got its start on Jeff Steber’s kitchen table. A self taught welder and born tinkerer, his first design was a 3“ full suspension cross country bike – at a time when everyone was still riding hardtails.

This was way back in 1990, when even downhill mountain bike races were being won by guys in full spandex. Many things have changed since that era, but one thing still remains, Intense Cycles’ commitment to doing things their own way.

Drop past the break to learn more…

Just behind the front office lays the assembly floor. Stacked on opposite sides of the room are carbon and aluminum front and rear triangles.

Carbon frames are received from overseas as just front and rear triangles.

Each is individually checked for quality before the bearings are pressed and final frame assembly may begin. If the only thing Intense manufactured was carbon frames, this would be the end of the tour, but every single aluminum frame bearing the Intense logo is hand built in their California facility.

Not only is every aluminum frame built in the United States, but so is every dropout and linkage. Jeff Steber and his team aren’t just passionate about building great bikes, they’re dedicated to making them locally. This commitment has been a boon not only to the local economy, but to the business as well.

Each top tube begins it’s life as a flat piece of aircraft grade aluminum that is pressed over an aluminum mold in a gigantic press, then CNC machines trim the pieces to size. It’s this process that gave Intense frames their unique shape. When Jeff first started building bikes out of his kitchen, the big companies wouldn’t talk to him. So he began to develop frames using this process, and it’s what gave the legendary M1 it’s iconic look.

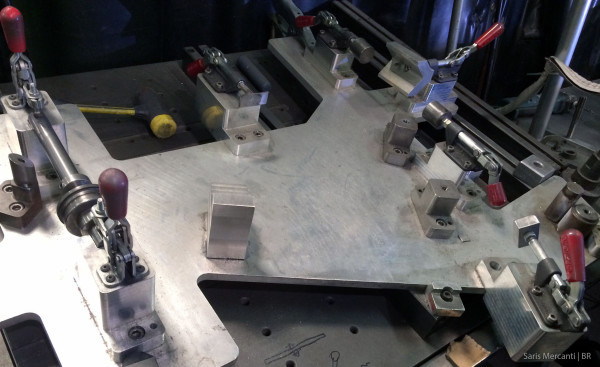

The press stamps out right and left specific molds which are then tacked together in custom jigs. Intense creates these jigs in house for every model.

These top tubes, jigs, tack welded frames, and a variety of other miscellaneous materials are stored directly across from the welding stations.

Depending on the frames on order, these materials are then collected and welded by Intense’s staff of expert welders.

As a result of a stupid (or shall we say inspired) inebriated conversation with Jeff, I found myself early the next morning fully kitted in leather gloves and a welder mask. Under the tutelage of the legendary Rick the Welder (pictured below) I had the privilege of attempting to lay down my first bead. The weld on the bottom left is what I was trying to emulate, the holes on the right are why I intend on keeping my day job.

On their premiere downhill frame, the Intense M9, Rick lays down more than 16 ft of beads. When RTW is not rocking a welder, his preferred tool is the throttle of his Harley Davidson, pictured on his station wall. Now in his 50s, Rick also still shreds downhill laps. Just left of the Harley is a picture of him crushing it on his M9 at the local race series.

Before the Aluminum frames can even hit the factory floor they’re subjected to a two-part heat treatment process. First, the frames are heated for one hour at 980 degrees Fahrenheit, then dropped into a special water bath, which cools them to room temperature in under ten seconds.

At this point, each frame is checked for straightness. The Aluminum has not been heat treated back to its final hardness and small imperfections can still be addressed in order to bring the frames back into tolerance. Once that quality control process is complete, the frames are sent back into the heat chamber for an additional eight hours at 350 degrees Fahrenheit.

The final quality control check on aluminum frames involves checking the head tube angle, shock link, seat tube, etc…. Every aluminum front and rear triangle manufactured in the factory is hand checked at this station before being sent to the painter.

The seat tubes are also reamed in ordered to ensure posts enter the frame smoothly.

From here the the frames are ready to be painted, and are sent out the door to the local powder coating facility.

When Intense first began making large batches of frames, they had to send them over an hour away (if you were lucky enough to avoid LA traffic) for painting, because the local painter was a one man shop whose facilities were unable to meet the companies growing demand. Although the local painter remained Intense’s go-to for small projects and prototypes, until Jeff hit on a remarkably simple idea.

Instead of wasting hours and money shipping the frames to and from the facility located in Los Angeles, he made the Temecula based painter a bold proposition. He offered the small business owner all of his business, some 40k annually at the time, if the man expanded into a large warehouse and hired more employees to meet Intense’s growing needs. It was a tough choice for a small business owner, but all of Intense’s aluminum frames are now painted locally – within the same business park.

In addition to the aluminum frame construction, Intense builds all of the items required for it’s aluminum bikes (headtubes, BB shells, etc), and the linkages, axles and hardware utilized by both it’s aluminum and carbon bikes.

To do so, they employ fifteen HAAS CNC machines running almost around the clock, and a plethora of other toys. As with their paint production, Intense was motivated to buy HAAS machines because they’re local. The company is the only CNC manufacturer still left in the US and produces their machines only two hours away. This makes service fast and parts easy to acquire.

Over the years, instead of investing heavily in magazine spreads and advertising, the company has focused on purchasing equipment. This high capacity machine has two jigs with a four sided vice, so the operator can unload and reload one while the other is still in operation.

Three of these HAAS machines produce only cylindrical parts.

These finished parts started their lives as the solid aluminum blocks pictured in the top right corner.

This heavy investment in machinery has paid off big dividends for Intense Cycles within the past two years. In that time frame, a craze for the not so new-new wheel size swept the industry, and the company was able to capitalize on the trend. The owners and product managers listened to rider feedback and were quickly able to make convertible dropouts for their frames. This enabled existing owners to easily upgrade to 27.5″ wheels.

In addition to their convertible dropout system, the company was also one of the first major players to bring a dedicated 27.5″ platform to the market. This was possible because the company has never been bogged down by bureaucracy. If Jeff has an idea, he can prototype it in a day, and be out testing it the next. It’s this flexibility that has lead to unusual prototypes like the 2951 and the company’s early acceptance of the tweener wheel craze. This first to market approach resulted in a 40% increase in revenue last year!

And now we that we have the back story, we can return to the assembly floor.

Where all of Intense’s frames are assembled and then packaged in boxes made locally.

Special thanks to everyone at Intense for the opportunity to tour the facility! The company has big things ahead of them, including a very special product launch Mid-March, and rumors of a new carbon downhill platform.