The all-new Hayes Radar disc brakes get a completely revamped design, from the fluid to the master cylinder, making for a simpler and (on paper) much better part.

The original Hayes HFX Mag brakes were introduced in 1997 and brought motorcycle stopping tech to mountain bikes. With them, they introduced 360º bladders, which allows a flip flop design, the post mount standard and the six bolt standards to the industry. In 1999, they introduced the split clamp lever design, and in 2000 standardized rotor thicknesses. Since then, plenty of iterations have followed from a number of brands while Hayes’ own subsequent introductions were relatively few and far between. Now, almost two decades later, they’re introducing a fresh aesthetic, a switch to mineral oil and a very user friendly design to kick off the next generation of Hayes brakes…

The new Radar brakes slot in between their Dyno (entry level) and Prime (higher end) models. They don’t replace anything, and are meant to compete at the same price range as Magura MT2, Avid Elixir 3 and Shimano Deore while offering a huge feature set for the $95 asking price.

They spent a lot of time with customers for feedback on brakes, and brought industrial design to their engineering department. The result is a sleek, smooth part with a good pivot location for the gloriously long lever.

Caliper’s use a 22mm piston (Prime’s have 26mm pistons) with an inside-mounted hose banjo and their excellent Crosshair alignment system. The pads insert from the bottom and use a top-mounted retention pin. They’ll come standard with sintered pads, semi-metallic are also available. They’re designed around their L-series rotor, shown, but rotors are sold separately in 140, 160 and 180mm sizes.

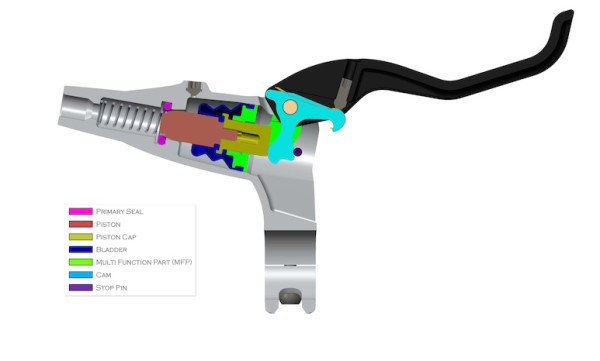

The big news here isn’t some crazy new technical innovation. It’s that they’ve refined the brakes and removed extra parts to make them more reliable. Compared to the Mags’ 25 parts, the Radar uses just 17 pieces. Some parts, like the bladder retainer, serve multiple duties to make it all simpler.

The 360º bladder is the accordion shaped bit shown above. The silver part sticking up from the lever (visible better in other photos) drives the piston into the master cylinder, which slides past the black rubber o-ring to close the system and start moving fluid down the hose to the caliper.

The split clamp makes them easy to install without removing your grips. It also means easy swaps from standard to moto style brake placement.

The Radar has a tooled reach adjust, accessed from the front of the lever. The bleed port is top and center, which would actually face down when installed…meaning you’ll probably have to rotate it or the bike up for service.

The brakes are designed for XC/Trail use, come in black only and weigh in at a claimed 280g (without rotor). We see plenty of opportunity for lower weights -a carbon lever blade is an easy start- with this platform.

The other big news is the switch to mineral oil over DOT fluid. Hayes says some OEM customers require it, and it’s generally much less toxic. It’s safe for paint and parts, particularly important for internal cable installations. It’s also safer for your skin, and it won’t absorb water.

As part of the switch, which you’ll see on future Hayes brakes, too, they have a new pro-level dual syringe bleed kit. Venom is a specially formulated mineral oil just for these brakes, so they recommend sticking to authorized parts for bleeds and service. Why? Mineral oil is completely unregulated, so they can’t say what would happen if you used someone else’s fluid. The brakes might work with other fluids but doing so will void warranty.

For consumers, brakes start shipping in June and will be supported by a complete selection of pads, rotors and accessories. For Shops, new service parts for the different fluid are ready to ship. Yes, this time, things should actually ship when promised (Primes were almost a year late coming to market). They made a big deal about this and recognize tardiness doesn’t help anyone.

Neither does poor performance, so they’ve had their sponsored athletes on them for a while, adding real world field testing to their own lab tests. The result? A lifetime leakproof guarantee. And early OEM placements on bikes from Specialized, Cube, Alutech and others.

They say the new optional pads are an extremely high quality semi metallic sintered pad standard with a special treatment that provides fastest burnishing in the industry. Break in should be very quick.

As an aside, they also showed off the new Hayes Reunion. It’s a quick connect hydraulic fitting for OEM customers only. Banjo or direct fitting, for DOT or Venom. Steel fitting can be reconnected and can be mounted at the lever or caliper. No re-bleeding required for up to 10 uses. It’s primarily made to ease internal cable installation, not as a travel disconnect.