Fabric might be a new, relatively unheard of component company but chances are good you’ve heard of the founders. Also known as the team behind Charge bikes in the UK, Fabric is the next evolution of their saddle technology with the intent of OEM spec. Charge had always wanted to get their saddles equipped on bicycles for the showroom floor, but selling a saddle linked to another brand of bike proved difficult.

Looking to be brand neutral, Fabric will be run alongside of Charge bikes in the UK, but their products will be soon offered as standard equipment on Cannondale bikes in the US. Cannondale seems like an easy choice due to Charge and Cannondale both being owned by Dorel, but Fabric still had to prove that their products were worthy of being sold on Cannondale’s highest end bikes. First pitched to Cannondale Product managers for OE spec in September, thanks to Fabric’s intriguing new technologies they finally got the nod after passing CSG’s rigorous testing – which according to Fabric is much more stringent than standard industry testing.

While most saddles utilize similar construction, Fabric has some truly innovative ways to produce some of the lightest and most comfortable saddles on the market…

Thanks to their past with designing and producing Charge’s extremely popular saddle, the Fabric team knew enough about saddle manufacturing that they knew if they wanted to make something truly new and exciting, they would have to look outside the traditional saddle construction channels.

For a while now, Charge has been working with Airbus to create 3D printed titanium parts for things like dropouts on their Ti frames. Initially, when the company set out to create a super high end seat, the goal was to use 3D printed titanium rails, matched to a carbon fiber base – that’s the pedestrian description. In reality, the design was incredibly complex utilizing hollow ti rails that acted as leaf spring with a high tech method of attachment to the saddle body. Instead of using glue or pockets, the ti rails had flat mounting points with dozens of tiny, 3D printed ti barbs that would be inserted into the carbon and bonded in place.

The design worked, but due to unforeseen difficulties in manufacturing on the carbon side the saddle ended up being prohibitively expensive for continued production. The first production run was already promised, so Fabric is following through, but the saddles will cost an insane $749.99. Surprisingly though, the limited run is mostly spoken for.

Fortunately, during the development of the ALM saddle the search for a manufacturer to address the carbon issues resulted in an unlikely find. After seeking out a composites expert that specializes in things like hockey sticks and sports equipment, they were offered a bit of advice. Fabric was hoping this new manufacturer would be able to assemble and produce the titanium railed ALM, but the unnamed composite maker then asked, why not make it completely from carbon fiber? The result would not only be easier to produce, but also result in a lighter weight saddle.

You have to understand this isn’t your standard saddle with carbon rails. Even the highest end carbon saddles these days are constructed from multiple pieces. What this company was suggesting was to mold the entire ALM in a single piece. After proving it could be done, it was an easy decision for Fabric to go with the new full carbon 1 piece saddles which will end up selling for almost half of the ti printed railed saddles, at $329.99.

The ALM saddles will be available for purchase by themselves but also will come as standard equipment on Cannondale’s Black Inc. bikes with actual Buffalo leather for the cover. In the spirit of matching, Fabric will also equip the Cannondales with Buffalo leather bar tape. Just don’t crash the bike since the Buffalo leather tape will retail alone for a hefty $129.99. But yes, it feels extremely nice on the hand.

Once the Ti ALM saddles are out of the picture, carbon ALM saddle will be sold in the Buffalo leather version without padding, and another version that forgoes the Buffalo in favor of additional padding. Fabric is also working on a naked carbon version which should be ready by Eurobike. Now, before you start thinking, “yeah, but what about comfort?” Fabric claims that the saddles are much more comfortable than competing carbon planks thanks to the flex engineered into the body. The saddle flex so much that initially, they had trouble with CSG’s testing since the body was hitting the bolt on the fixture. As it turns out, the fixture was running an improperly large bolt but most other saddles didn’t flex enough for it to be an issue. Once the proper bolt was installed, the saddle passed with flying colors.

The comfort aspect comes from Charge’s development of the Scoop saddle which uses a solid nylon base. Thanks to the Scoops incredible popularity, the model will continue under the Fabric label but in 4 levels, each in 3 curvatures. Each Scoop saddle uses lightweight Polyurethane foam that has a cover heat vacuum bonded over the top. Then the pieces sit into recesses in the saddle base and bonded in place. The design is super clean, and since the cover is vacuum bonded together instead of glued it results in a softer saddle with edges that won’t come loose. Fabric claims the glue for the edges is stronger than the cover so it won’t pull out.

Offered in Flat, Shallow, and Radius, the Scoop saddles gradually get more curvy and add more cushion which creates saddles suited to different riding styles. Flat Scoops are designed for aggressive road positions, while the Radius Scoop is for more upright positions at the other end of the spectrum. Then each of those sizes will be offered in the Elite, Race, Pro, and Ultimate with hollow cro-mo rails, hollow ti rails, carbon fiber rails, and then carbon rails with a carbon base respectively. Pricing is set at $69.99, $79.99, $179.99, and $279.99 and include multiple colors.

Fabric is also working on a few other new saddles including the Line and the Cell. Originally not keen on making a saddle with a cutout due to the comfort built into the Scoop, Fabric has set out to produce a saddle with a relief channel in their own style. Being based in the UK, Fabric doesn’t like the idea of a hold through the saddle which lets in spray from the rear tire, so the Line uses a solid base but still has a full relief channel that still allows air to flow across the saddle. Pricing TBD.

In another instance of looking outside the saddle industry for new ideas, Fabric sought technology for the Cell from an unlikely source – the athletic shoe industry. Thinking along the lines of athletic shoe outsole which are created from multiple materials in a single mold, the Cell uses a Polyurethane cover that isn’t completely air tight. Think shoes with the air bubble in the heel. The unique Hex Air Cell cover is matched to a solid base for a durable, comfortable, and eye catching new saddle design. The blue Cell above is still a rapid prototype, and Fabric mentioned the production Cells will use different colors for the cover in more of a satin finish. Price is TBD.

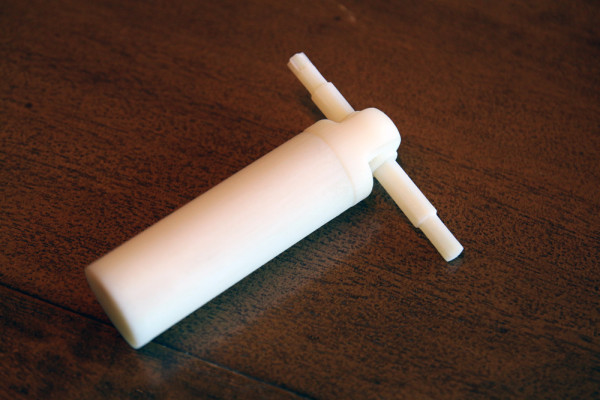

Fabric even showed off their 3D rendering of a new multi tool. Featuring a ratchet design with tools stored in the handle, this little guy could be a winner once it makes it to real life.

Finally, Fabric also has a line of appealing bar tape and grips. Obviously, the Buffalo tape is extremely expensive at $129.99, but their Knurled rubber tape is much more reasonable at $29.99. The grips are also$29.99 and offer an interesting lock on design with a rubber grip bonded to the plastic base. To make the grips as light as possible, holes are made all the way through which gives them a unique look.

In the immediate future, Fabric will be sold through Cannondale dealers nation wide, though the distribution may include dealers of other CSG brands in the future. This will include a demo program, where saddles can be mounted to cyclist’s bikes to try out the different shapes (currently limited to the scoop).