Photo credit: Specialized / Dan Barham

Photo credit: Specialized / Dan Barham

Just like apple pie, when it comes to wheels, bigger is definitely better. This time though, the big industry push isn’t towards larger hoops, but rather wider internal rim diameters.

It’s not a novel concept, but one that has only recently gained traction, and is strongly backed by on the trail performance, and lab testing.

For the team at Specialized, the come-to-jesus moment of realization was due (strangely enough) to fat bikes. Though sometimes pejoratively referred to as snow bikes, the clown soled fatties can be quite fun on the trails because of the traction provided by their gargantuan tires and rims. During the development of the Specialized Fatboy, Sr Design Engineer Jason Chamberlain discovered just that, and an idea was born.

For the team at Specialized, the come-to-jesus moment of realization was due (strangely enough) to fat bikes. Though sometimes pejoratively referred to as snow bikes, the clown soled fatties can be quite fun on the trails because of the traction provided by their gargantuan tires and rims. During the development of the Specialized Fatboy, Sr Design Engineer Jason Chamberlain discovered just that, and an idea was born.

To prove the concept, the engineering team used an angled grip table to simulate leaning a bike over in a corner. This helped them visualize what happens to tires at load, and proved the wider is better concept wasn’t just a placebo.

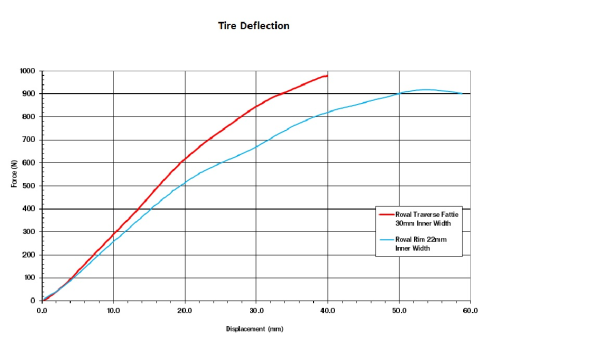

Studying the graph, you can see that the tire on the wider rim moves less under the same amount of force, which translates to better support and handling on the trail.

Photo credit: Specialized / Dan Barham

Photo credit: Specialized / Dan Barham

While wider is better, the downside is having to add extra material, which means more weight. Early mountain bikers ran into this same issue. During the first days of klunking, the Araya 7x had a 25mm inner diameter and were the defacto rim of choice, but the pursuit of lower rotational weight led innovators like Keith Bontrager to start trimming down road rims to klunker scale.

From the original 22m ID of the Roval rims to the 30mm ID of these Fatties, the improvement in traction is massive, but Specialized found anything wider offered only diminishing returns.

Photo credit: Specialized / Dan Barham

Photo credit: Specialized / Dan Barham

The wheels are available in 27.5″ and 29″ sizes only, at two different price points. The carbon model retails for $1,400 USD, while the aluminum models are priced at a more attainable $600.

Weight for the carbon 29″ wheelset is 1,570g, while the 650B models hits the scales at 1,530. The aluminum 29″ wheelset is 1,770 g, and the 650B version is 1,690 (weights do not include valve stem, rim strips, or decals).

Photo credit: Specialized / Dan Barham

Photo credit: Specialized / Dan Barham

The front hub is convertible between 15/20mm with different end caps, while the rear hub has 135mm, 142/142+, and XX1 compatibility.

Both wheelsets make use of DT Swiss Revolution spokes and hub internals, although the Carbon model utilizes a higher 56 T point engagement.  Wheels will be shipped with traditional rim strips, but the carbon model will also include these Roval plugs. Lighter than a traditional tape setup, these Delrin plugs seal the spoke holes and can be run either with a tube or tubeless.

Wheels will be shipped with traditional rim strips, but the carbon model will also include these Roval plugs. Lighter than a traditional tape setup, these Delrin plugs seal the spoke holes and can be run either with a tube or tubeless.

Photo credit: Specialized / Dan Barham

Photo credit: Specialized / Dan Barham

The rims will also be available with three different colored Vinyl decals, for optimum color optimization.

For more info, visit Specialized