If you’re a fan of DIY, you might want to check out the Bamboobee Bike’s BIY kit. Designed as an economical way to get your own bamboo frame, the kit takes is a step further by providing the raw materials to build a frame along with some instruction. If you have been longing for the satisfaction of building your own bicycle frame, this is probably as easy as it gets – until Lego makes a life size, rideable bike that is.

Initially, frame kits will be limited to a “cross country” style design with a sloping top tube since Bamboobee has found this design to be the most versatile. Available in 3 sizes, they are listed at Small for riders under 5’7″, Medium for 5’7″-5’11”, and Large for riders taller than 5’11”. Optional top ups are available to add disc brakes or a belt drive to the bike.

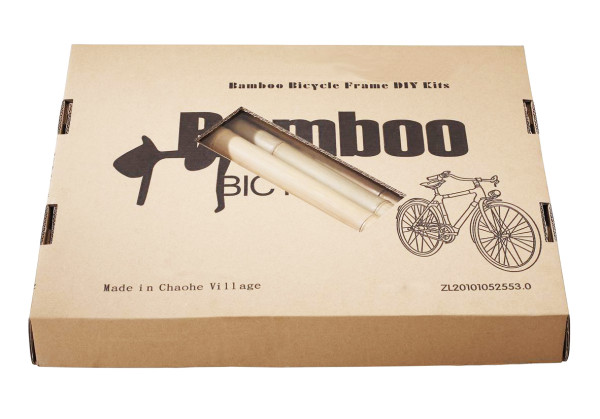

Inside the box you will find all of the raw material to build a frame from scratch with the exception of the epoxy. Bamboobee isn’t able to ship the epoxy with the kits without getting a special permit, so they recommend getting it locally and provide a link to find the West System Epoxy. Otherwise the kit has all you need including pre-mitered bamboo tubes, 25 meters of hemp fiber, a one time use frame jig, 6 cable holders, dropouts, aluminum tubes for the head tube, BB, and seat tube, as well as a file, metal wire, tape, and instructions.

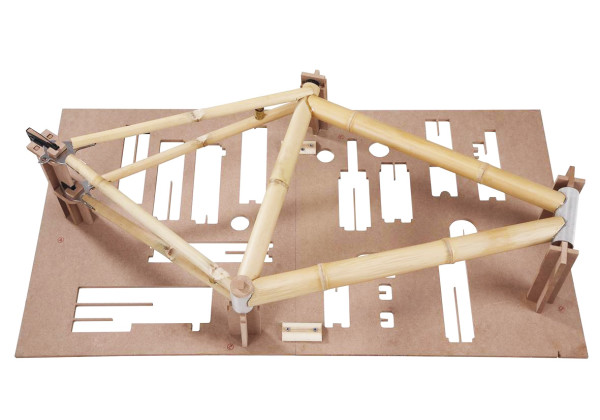

All of the jig supports cleverly pop out of the sheet that acts as the base, and builders can go to work assembling the tubes. Once everything is in position the joints are wrapped in the hemp fiber which is then covered with the epoxy. After the epoxy has dried the third day, the joints are then sanded to clean up the rough edges. The process is said to take 3 days and probably won’t result in the super clean joints you see on the professionally finished bikes, but hey, you built it yourself.

Currently available through the Kickstarter for just $169 per kit (after earlybird special price goes up to $179), frame kits will require an additional $30 shipping and do not include any bike parts. Expected delivery of the frame kits is set for February 2015.