You can’t say you didn’t see this one coming. Most of the newer road and cyclocross bikes equipped with disc brakes are also starting to come with thru axles front and rear. For a wheel manufacturer like Zipp without compatible hubs, that meant something new was certainly in the works. In fact, keen observers may have spotted the new design under some of the best cyclocross racers in the world with Jeremy Powers racing on them for an entire season including winning the National Championship title. Serving as the centerpiece for the new wheels, Zipp wanted to make absolutely sure the new hubs would provide the service life needed especially for cross. Admitting they’ve struggled a bit with bearing durability in the past, J-Pow was able to race an entire cross season on the same bearings, pressure washers and all.

Even if cyclocross isn’t your main focus, the new Firecrest 202 Clincher and 303 Clincher and Tubular have a little something for everyone. They’re lighter, cheaper, and more importantly – much more versatile. Get all the details plus actual weights next…

Firecrest wheels have always been about cutting edge aerodynamics, and the disc brake models are no different. At least when it comes to the rims. That’s due to the fact that the rims are the same that you would find on the previous Firecrest disc brake models. Crafted to obtain the greatest aerodynamic benefit with the least wind-induced steering torque, Zipp relies heavily on both CFD and wind tunnel testing to develop the rim profiles.

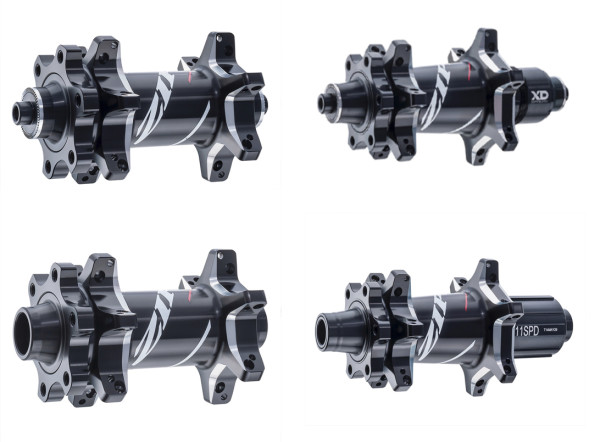

Since the rims don’t change however, the real story is of course the hub. Officially named the 77/177D, the disc hubs mark a fairly large departure from the previous 88/188D design. Each hub uses an all new flange geometry with opposing straight pull spokes. Shipped as standard quick release, both hubs use end caps that can be swapped by hand to run 15×100 or the new 12×100 front standard and 12×142 or 12×135 in the rear. All aftermarket wheelsets will include the additional end caps along with rim tape (clincher only), skewers, and valve extensions.

You may also notice the lack of any preload devices or set screws. That’s because the bearing preload is preset which allows the bearings to have better sealing to protect them from the rigors of cross. According to Zipp the previous design, while offering less friction, was changed for the 77/177D specifically since the wheels would benefit more from increased bearing protection.

Manufactured in SRAM’s Shen Kang factory in Taiwan the production efficiencies, as Zipp likes to call them, related to the hubs results in a significant decrease in price – from $2,800 to $2,400. Still not exactly cheap, but you are getting lighter, more compatible wheels for $400 less. The wheels are all still hand built in Indianapolis with rims that are made right in the same facility.

Using a pretty typical 3 pawl freewheel with 10 degrees/36 points of engagement, Zipp raised a few eyebrows at the launch when they mentioned the hubs would have a compatible XD freehub body available separately. The inclusion of the XD driver was justified by claiming it allows for franken-bike builds where riders may need big gearing for their gravel, cross, or even mountain bikes. While not a bad idea, we wouldn’t be surprised to see something a little more road or cross focused that utilizes the XD freehub from SRAM in the near future based on this little addition. The standard freehub body is SRAM/Shimano 11 speed compatible and there will be a Campagnolo option as well.

Claimed weight on the hubs is listed at 145g/265g with QR and 140g/260g with TA end caps.

Also new are the Zipp quick releases included with each wheelset. Still based on an external cam design, the levers have been reshaped with a wider, more ergonomic shape to make opening and closing the skewers easier and more comfortable.

Available in only stainless steel shafts, the skewers check in at 88g for the pair.

Other than the rim itself, the only other distinguishing factor between the 202 and the 303 Firecrest Disc Brake wheels lies in the nipples. Since the shallower 202 rim design intrinsically places more stress on the nipple, the 202s are laced with brass nipples instead of the black alloy nipples found on both 303s. Both styles use Sapim’s Secure-lock nipple which are threaded to CX-Ray spokes.

Originally developed to be the first carbon rim to survive Paris Roubaix, the Firecrest rim profile keeps its wide shape with a 17.5mm internal width and 25.4 or 28.5mm max external widths.

Specifications:

Zipp 202 Firecrest Carbon Clincher Disc Brake

• 1,530g per Wheelset Claimed

• 32mm Wheel Depth

• 25.40mm Max Width

• 24 Rear Spoke Count

• 24 Front Spoke Count

• Sapim Brass Secure-lock nipples

• Sapim CX-Ray Spokes

• 77/177D Hubs

• Available in 10/11-Speed Cassette Body

• Retail Availability: March 2015

• Front Wheel: $1,100, €980, £835

• Rear Wheel: $1,300, €1,155, £990

Actual weight came in 15g lower than claimed at 1515g for the set without rim tape, skewers, and with the thru axle end caps.

Zipp 303 Firecrest Carbon Clincher Disc Brake

• 1,645g per Wheelset

• 45mm Wheel Depth

• 28.50mm Max Width

• 24 Rear Spoke Count

• 24 Front Spoke Count

• Sapim Secure-lock nipples

• Sapim CX-Ray Spokes

• 77/177D Hubs

• Available in 10/11-Speed Cassette Body

• Retail Availability: March 2015

• Front Wheel: $1,100, €980, £835

• Rear Wheel: $1,300, €1,155, £990

Actual weight came in at 1,654g without skewers or tape and QR axle caps.

Zipp 303 Firecrest Tubular Disc Brake

• 1,400g per Wheelset Claimed

• 45mm Wheel Depth

• 28.50mm Max Width

• 24 Rear Spoke Count

• 24 Front Spoke Count

• Sapim Secure-lock nipples

• Sapim CX-Ray Spokes

• 77/177D Hubs

• Available in 10/11-Speed Cassette Body

• Retail Availability: March 2015

• Front Wheel: $1,050, €935, £800

• Rear Wheel: $1,250, €1,110, £950

Actual weight came in just a bit over with 1,424g without skewers and with the QR end caps.

All three disc brake versions of the new wheels should be available later this month – a fact that was validated after seeing nearly finished wheels waiting for testing. Part two of our visit to Zipp’s facility in Indianapolis, IN will include a full tour. Well, at least what we were allowed to see!