It wasn’t long after Abbey bike tools started making products that Jason Quade started getting requests for a bearing press. Like most of his tools though, he didn’t want to make something just to make it. It had to work better and make the task at hand easier to get the Abbey seal of approval.

Jason has been hinting that he had been working on a bearing press for sometime, but this is the first time we’ve seen it in person. Built using a modular design, the tool will be adaptable to just about any frame and should make the process of installing press fit bottom brackets or headsets much easier down the line…

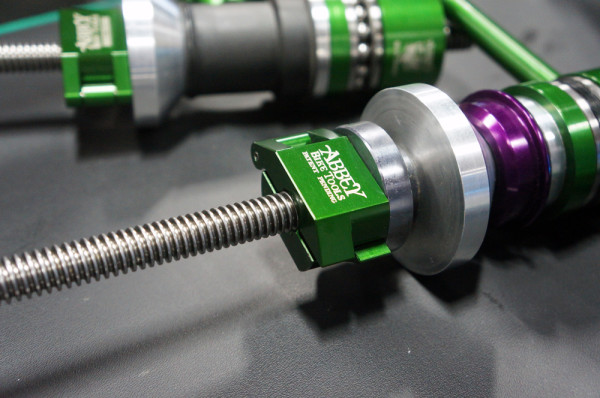

One of the key elements of the bearing press is the addition of a thrust bearing in the press head. Jason says the inclusion of this bearing reduces the amount of force needed so much that he will be able to offer a version without handles, instead relying on a knurled top cap. Above, the bearing is shown without the shield but the tool will ship with the black protective casing shown below.

The version without handles will include deep grooves in the cap for grip which isn’t shown on the tool above, and the handleless version will also include an Allen fitting for an 8 mm wrench if you need extra torque. Due to the extra machining needed to produce the Allen fitting, both versions will have similar price tags meaning the handleless version will probably appeal to those traveling with their tools. Jason mentioned that almost all of his testers using early prototypes have said the tool works well enough that the handles are unnecessary.

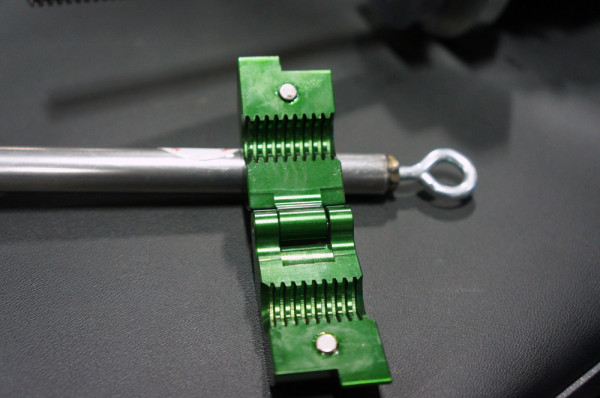

One of the best features in our opinion, is the custom split nut which uses powerful magnets to open and close. Not only does this prevent you from having to thread a nut on the shaft for what seems like hours, but it also eliminates the pinch threat from quick release nuts that all mechanics have probably experienced at least once in their life. The split nuts clamp onto a standard Acme thread which allows the tool shaft to be extendable with coupling nuts for bikes with excessively long head tubes.

The bearing press will also include a big centering cone to ensure the bearings press in nice and square. Currently the tool is only compatible with its own fittings, but Jason is working on building a set of adapters to allow it to work with other headset adapters and fittings. Pricing is expected to run $180 for the press itself (with or without handles) and up to $250 for a complete tool and adapter set.

We’ve seen Abbey’s suspension top cap sockets before, but now they are ready to roll and shipping out to happy mechanics. The sockets mean you will no longer need to grind down conventional sockets to properly fit suspension top caps, and the precision machined aluminum not only fits better but should prevent damage to the top caps as well. Machined with zero lead-in for a tight fit, the sockets also include finger splines to help turn the tool without the 3/8″ Square Drive wrench. Abbey’s sockets are also shorter at 25 mm tall which should keep them from slipping off. Sold only in a set of five including 24, 26, 28, 30, and 32 mm, all five sell for $150.

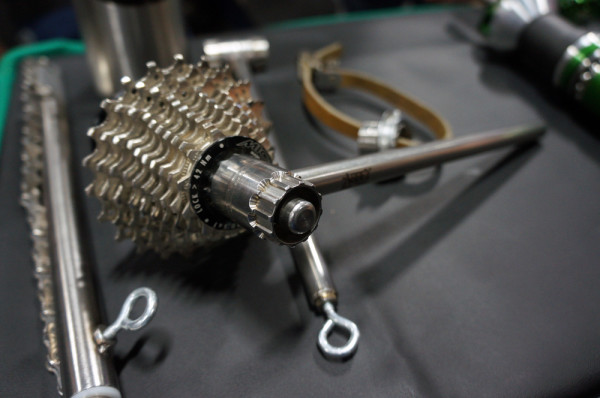

In the spirit of continuous improvement, Abbey now offers a Crombie tool with a side for 12mm thru axles. This particular tool uses a standard Shimano HG spline on one side allowing for classic Crombie usage without removing the quick release. But it also includes a 12mm thru axle fitting on the other side to make installing HG cassette lockrings on thru axle hubs a bit easier.