If Mavrick had a bike, I imagine this is the one he would ride into the Danger Zone. Dimond Bikes’s made-in-USA carbon frames have only been around since 2013, but they arrived carrying a very big beam stick. In addition to impressive wind-tunnel results, this past October, Dimond pro Maik Twelsiek delivered the best bike split of the day at The Kona Ironman World Championships giving this new brand some serious street cred.

See why these bikes are so freaking fast and some of the custom paint jobs they can do for you…

We first saw Dimond bikes a couple of years ago. The direct to consumer brand was born when pro Triathlete TJ Tollakson and former Zipp engineer David Morse started off trying to come up with a new hydration system. In what was an ironic series of events the two friends who were both well established in all things aero in the cycling industry, they got started with a wedding gift. The “something old, something new” got taken to a new level in 2010 when Morse gave Tollakson something “old”… in cycling terms, REALLY old. An early to mid 90’s Zipp 2001 frame, (pictured above with a Dimond decal). They took the 17+ year old frame that was designed for a 7 speed drivetrain and modified it to fit current tech. Check out that 1-inch headtube! Though a few cogs old, the “2001” was still considered one of the fastest frames available.

Every Dimond frame is designed and manufactured in Des Moines, IA. Though not a “diamond” frame, according to their website,

“It takes heat, pressure and carbon to make a diamond gemstone. Similarly, it takes heat, pressure, and carbon to create the Dimond bicycle. While the physical similarities between the two may end there, one thing is certain; with a Dimond bike, you can be brilliant under pressure.”

Their new flagship, the Dimond Brilliant adds their new Superfork to their already fast Dimond Express frame. The Superfork uses a magnetic cover on the fork that can be easily removed but stays on while riding. The Superfork houses either TriRig Omega or Omega X brakes and keeps them protected from the wind. But the removable cover should make the brakes easy to access for maintenance. The Dimond comes built with 2 optional kits including a Race Build with Ultegra Di2 ($9,875) or the Premium Build with Dura Ace Di2 ($13,595). It is also available as a frameset with the Superfork ($6,850). While you’re at it, since it’ll just be a drop in the bucket at this point, custom paint can be had starting at $500.

The slightly more budget friendly Dimond Express loses the Superfork for a 3T Funda aero fork. The Express is available as a frameset ($4,000) or complete with an Ultegra Di2 kit ($5,950), and comes in any color you want as long as it’s black.

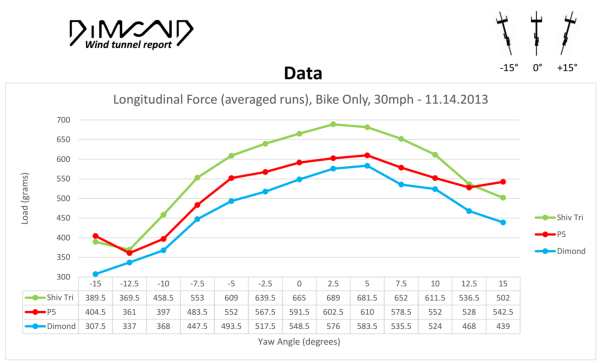

Ironman course time savings over our closest competitors:

| Average Wind Yaw | Cervélo P5-3 | Specialized Shiv |

|---|---|---|

| 0° | 1min 46sec | 4min 46sec |

| 5° | 2min 30sec | 4min 56sec |

| 10° | 1min 21sec | 4min 13sec |

| 15° | 4min 31sec | 3min 50sec |

Their detailed wind tunnel test put the Dimond Express up against some of the big players and shows some significant results. The bike’s design obviously shines when there is any sort of side wind…. which unless you’re on a straight road with either a perfect head or tail wind, is what really matters. Regardless of what any data says, they seem to be backing it up in the field where it counts.

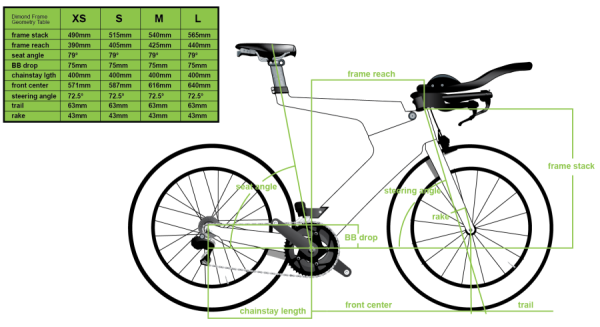

The Dimond family of bikes come in XS, S, M & L, but have a short headtube allowing a wide range of stack height and fit options. Check out some of the custom paint options as well as a video on their backstory below.