If you’re in the business of selling precision bearings, your product has to start with precise assembly. Looking to speed up their assembly process, Kogel Bearings wanted to avoid the use of an arbor press which could damage the bearings. But they also were in need of something faster than the threaded solution that was currently employed. After seeing the custom carbon, machining, and tool work of Joshua Clark from Velo Gold Bicycles (on Bikerumor, no less), Ard Kessels of Kogel contacted Joshua to see what he could do.

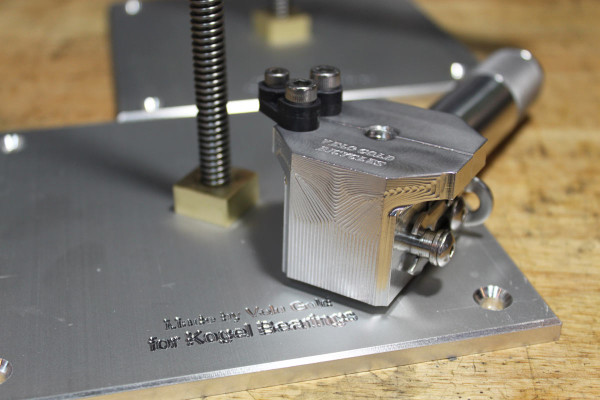

The result is an impressive looking tool/assembly station with some beautiful machining…

According to Joshua, the tools are working prototypes that were designed on short order for Kogel. As the ever present tinkerer, inventor, and machinist, Joshua states there are already some tweaks that he’s thought of that could make them more bike shop/general purpose friendly. Designed and made in house at Velo Gold in Ft. Worth, Texas with the exception of the slide snap latch, the bearing tool has a split nut head that clamps to an ACME 3/8″-12 threaded rod. The split nut performs much like that of the new Abbey Bike Tools bearing press, but closes with a slide snap latch instead of magnets for a tool that is geared more towards production assembly. The ease of the split nut should make installing bearings and assembling bottom brackets quite a bit faster, while keeping the delicate hand touch needed to ensure the bearings aren’t over loaded in a press.

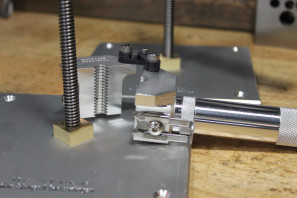

Joshua also mentioned this is the “(mostly) proper” installation technique for the new assembly tool shown above. Currently there are no plans for production other than for Kogel’s assembly team, but like all things – if there was enough demand…