Although it isn’t the method of choice for any large bicycle manufacturers, it would be cool to see more effort go into creating CNC machined frames, if only because they tend to look pretty awesome! This eye catching downhill bike was built by Stewart Palmer, a fifth generation engineer with past experience machining F1 race car components and high performance engine parts.

After his Dad’s job became redundant, Stewart’s parents founded North Bucks Machining in 2011 and took their son and daughter on as employees. Stewart enjoys riding in his spare time, and with the dream of creating his own project suddenly possible he spent 18 months designing and building his first bike frame…

Although North Bucks Machining started out with 3-axis machines, Stewart wanted to utilize his past expertise and push NBM into more sophisticated 5-axis manufacturing. The company now uses a Quasar 5-axis machining center and Open Mind’s HyperMILL cam software, an upgrade that made the bike project possible.

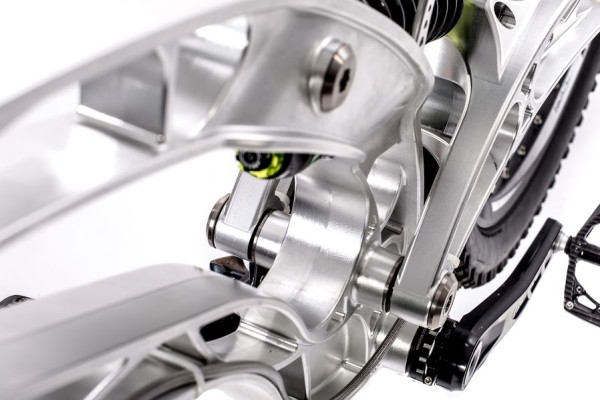

Working from Stewart’s sketches of the frame a company called Laser Scanning created a 3-D model, then virtually simulated loads and stresses on the design before the machine work began. Stewarts aim was to improve upon the strength and structural integrity of traditional mountain bike frames. Since hollow tubes have inherent weak points at every weld, he cut his frame from solid billet aluminum and scalloped out unneeded material to keep the weight as low as possible.

The NBM Bike’s frame is comprised of three parts- the main frame, the seat post and the swingarm, and it’s amazing how much aluminum is left on the factory floor- The main frame was machined out of a 100kg block of aluminum, and cut down to a 4.5kg front triangle. The seat post goes from a 15kg block to a 250g piece, and the 2kg swingarm is cut from a 50kg chunk.

It took 40 hours to machine the main frame, 18 hours for the swingarm and 15 hours for the seat post. This is a costly and slow method of production, but at this stage the company isn’t trying to make a mass consumer bike, they are only seeking to prove Stewart’s concepts. The bike project also helps NBM fine-tune their processes to produce the best possible surface finishes. With the capabilities of HyperMILL’s advanced finishing machining cycles, the bike’s pieces come off the mill ready to assemble and ship, with no further hand finishing required.

Stewart does intend to reduce the machining time by employing Hypermill MAXX software for rough machining. With this software and a faster spinning CNC machine, production time could be reduced by up to 80% in the future. Stewart also plans to keep shaving weight off the 6.75kg frame until it sits around 5kg (11lbs). Given his F1 experience, strategic weight reduction is nothing new to him. Once the design has seen these revisions, NBM hopes to eventually retail the next generation frames for about $9,820 USD and as a complete top-tier build for roughly $14,030.

Stewart says he’s ridden the bike but hasn’t had a chance to push it to its limits, so unfortunately we don’t have much info on how it actually performs on the trail. Interested riders can contact NBM for more information on the project, and if you’re anywhere near Birmingham, UK, the bike will be on display at the MACH 2016 manufacturing exhibition from April 11-15th.

H/T to Rhys Williams at Pulse PR