We’ve seen two new road helmets from Catlike this spring, the more affordable Olula and the convertible aero Cloud 352. Both helmets have been out this year racing on the heads of Catlike’s sponsored World Tour and Pro Conti teams, but when they were introduced Catlike didn’t elaborate on how they were being made differently than other helmets on the market. What we’ve learned now is that by combining two different types of foam – EPS and PPE – Catlike are able to shape a lightweight helmet that retains more protection even after the first impact. While that won’t mean that you don’t have to replace your lid after a crash, you will be much safer if you end up tumbling down the road or trail…

Catlike has been pushing materials tech to boost safety for some time, having claimed to use Graphene more than two years combined with an Aramid skeleton molded into their Mixino helmets to ensure that it stays together in a major crash. This latest joining of materials takes that prolonged safety in a crash one step farther. It does that by bringing together the typical EPS found in helmets, with the less common PPE to reap some benefits from both.

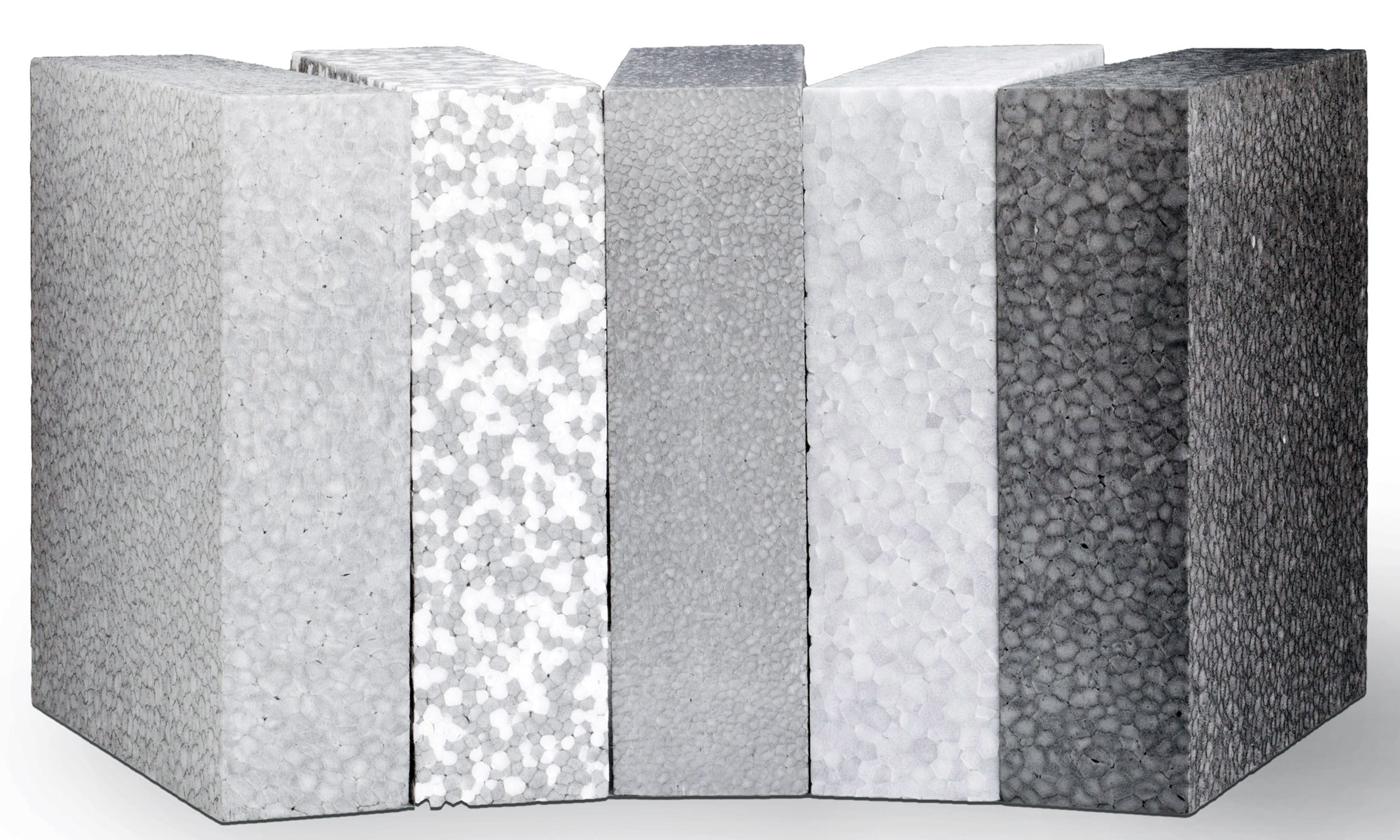

Expanded polystyrene (EPS) is the light and durable foam that makes up the majority of most helmets, and can be easily molded into complex helmet shapes. While it does not break down from environmental factors like temperature changes, moisture exposure, or light; it is only safe for just one impact. Once it absorbs an impact, the foam is permanently deformed and must be replaced. Polyphenylene ether (PPE) on the other hand is a more resilient foam, often used in the construction of buildings and car safety systems. The loose and lightweight beads outperform EPS in that they can absorb the energy from multiple impacts without suffering structural damage or losing their shape.

But PPE cannot be as easily shaped into complex forms. So by mixing PPE into the EPS, Catlike is able to create the same initial impact absorption performance. But with the PPE embedded in the other foam, the helmet retains some impact absorption for subsequent hits. The conventional thinking in the helmet industry had been that the force of the initial impact was the most important to absorb, as those after tend to have less energy. But now with this new tech, some protection will carry over, even after the EPS element of the helmet’s protection has been crushed by the first strike.

The new 130€ Olula and 180€ Cloud 352 are the first two helmets on the market to use this new tech, and will be available to purchase everywhere Catlike helmets are sold by the end of this month.