If you could design the perfect drive mechanism, what would it be? High engagement? Low drag? Quiet? Those were the answers Project 321 were looking for when they set out to design a new drive system. It seems that riders are still split between loud and quiet hubs, so they thought – why not do both? More importantly, while the new drive system allows the rider to choose the volume of their pawls, it also creates a system that claims to have far less drag while keeping the high degree of engagement, all with fewer moving parts…

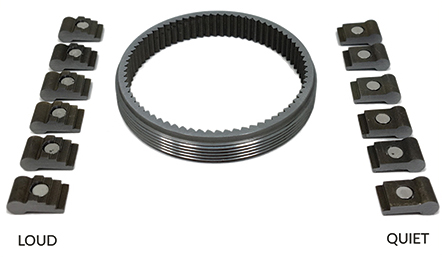

The secret to the P321 Drive system lies in their magnetic pawls. But how do they work? Project 321 says the key to the design is that unlike a traditional pawl spring, the magnetic pawls offer the greatest pawl force against the drive ring when the pawl is fully engaged as the magnet pulls the pawl into the drive ring. As the pawl gets father from the drive ring teeth during freewheeling, the force and therefor drag is reduced. Project 321 says this is the exact opposite of a traditional mechanical push spring and that when the pawls are disengaged for freewheeling, the drag is at its highest since the spring is compressed and being pushed back into the drive ring.

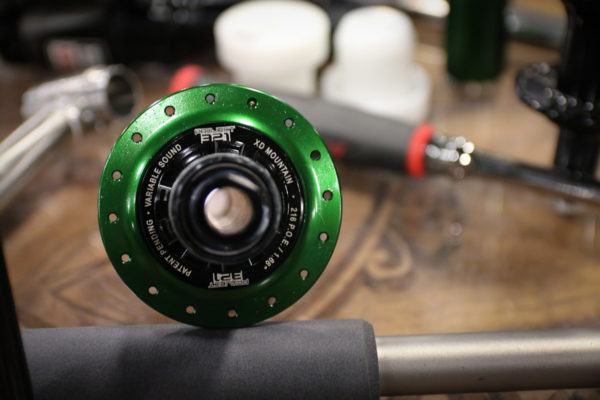

The P321 Drive System uses 6 magnetic pawls in a 6×2 or 6×3 driver configuration where only two or three pawls engage at one time. The 6×2 drive is the standard option which provides 216 points of engagement at 1.66°. The 6×3 driver is really only necessary for tandems, e-bikes, or riders over 275lbs and drops the engagement to 144 points or 2.5°. Either option includes a 3 year warranty on the driver.

As for the sound options, there are two different pawl sets, one for loud and one for quiet. You can get a sense of the difference in the video above, but it’s a substantial change. The two sets of pawls have a different shape, mass, and magnet, which changes the sound of the hub. It also changes the drag with the quiet pawls offering a claimed 68% less drag and the loud pawls offering 51% less drag than their previous system (Industry Nine).

Then there is the oil volume of the hub which isn’t something we typically think about. Project 321 actually increased the oil volume by adding a bunch of machined holes under the driver in the hub shell. They say this will not only help dampen the sound further, but also increases the time between service intervals. The only part that moves on the drive system are the 6 pawls and the driver body itself.

Even though Project 321 now offers the P321 Drive System on all of their rear hubs, the system is also backwards compatible with current G2 hub shells. Project 321 claims that they have had zero hub shell failures of the current G2 design, so they extended the warranty to 10 years for the axle and hub shell, as well as made the new driver backwards compatible. Available for XD or Shimano, SS, Boost, and nearly every axle configuration, a hubset will run about $600 with pricing on the driver itself TBA.