The engineers at lightweight specialist Tune have been working to address the ongoing concerns of road disc brakes in the pro peloton for quite some time, and are getting ready to make their solution official. It seems that rotor guards are going to be come a real thing as a result of a few very vocal professionals. Tune have just shared with us a series of images of their most recent prototype disc brake rotor safety covers in what they are calling Project Disc Sheath. Thinking about a way to offer protection to calm the ongoing debate between the CPA & UCI, Tune is proposing a versatile safety cover that will work with a number of frames & forks to quell some of the fears about the dangers of hot, spinning rotors in the event of pile-ups in the peloton. Spin past the break with us to get a good look at Tune’s solution…

Tune’s Disc Sheath is designed to work with the 160mm rotors that have been agreed for use by the pros, and provides wrap-around protection of the sharp top edge of the rotors as well as extended protection from the side for the lower portion of the rotor. We asked them about 140mm rotors, and Tune tells us that they see less & less of the smaller rotors being spec’d on new bikes, but are open to working with pro teams or OEMs that see the need for a protection solution for other rotor sizes.

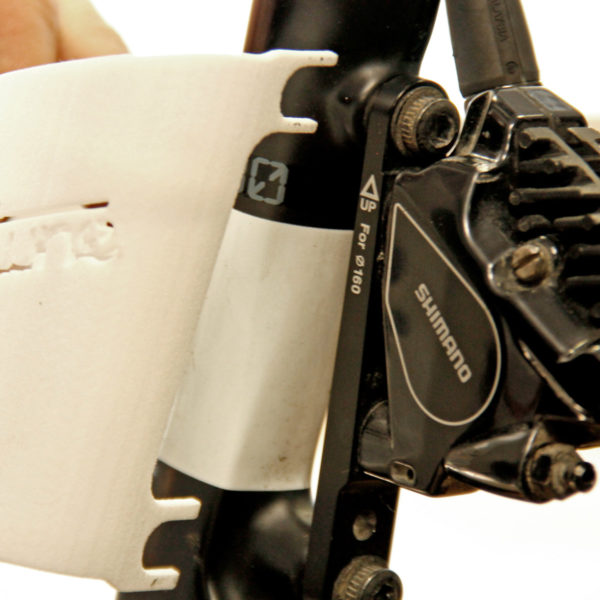

The Disc Sheaths work by simply mounting in between the flat mount brake mounts and the actual brake calipers (after you install a set of special alloy brake mount washers that ensure you can properly torque your brakes.). This moves the brake pads about 2mm further from the frame or fork, which may effectively reduce pad contact with the rotors by around half that distance. Tune sees that as a reasonable compromise to offer an almost universal fit to any frameset using the flat mount standard. This mounting style also allows for a bit of lateral adjustability so they can be tuned to perfectly fit around a variety of tube shapes and then secured in place with the brake caliper.

The design and layout also means that keeping their fixing point away from axle and wrapping around only on the upper portion of the rotor, quick wheel changes can happen with out the disc cover getting in the way, making them race friendly for both professional and amateur cyclists.

The covers are designed in a shaped way to offer stiffness to remain stable in the wind so they do not make noise on their own or allow enough flex to rub the rotors even when you get out of the saddle to climb or sprint. The covers themselves also get a strategically perforated design that minimizes their aerodynamic impact on the bike, while still providing ample airflow over the rotors for cooling.

These images are of course of their most up-to-date 3D printed prototypes, which have been developed to refine the complex shaping before the final models will be produced in molded carbon fiber to deliver the light weight and stiffness that Tune specializes in. No retail pricing has been set as that will depend a lot on the final carbon materials selected and the amount of labor that will be required to produce each one. Tune did have a production timeline in mind though, anticipating that final versions will be available to consumers and pros alike at the start of September, just after Eurobike.