We’ve seen plenty of bike frames made out of wood over the past few years, but few have taken advantage of the material’s workability to add more customization into the frame building process. My Esel takes that issue head on. While their plywood-based bikes built in Austria will surely appeal to some cyclists’ sensibilities, it is really their customization process that make the bikes unique. For each bike that they produce, My Esel uses a configuration tool that lets buyers enter their exact body measurements and desired riding position, to scale the frame fit specifically to them, before it is produced through a CNC manufacturing process tailored to each buyer….

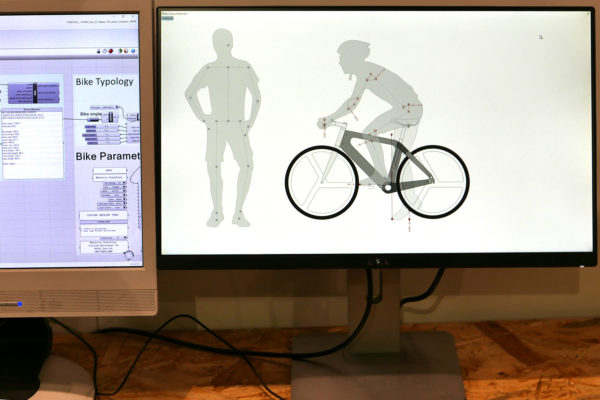

The way My Esel puts it “the bike should adapt to its rider – not the other way round”. The key to that customization has been developing a parametric design software that lets My Esel plug in all of the key measurements of a rider’s body and translate that into a scalable frame layout part of which is then produced on a CNC mill. You have longer than normal lower legs? The software can accommodate a taller seat height without impacting reach.

The software also adjust to three primary riding styles Sport/Racing, Urban/Trekking, or Comfort/Holland (a lot of buyers are looking for upright fit commuters) so you not only get a bike the right size for you put with a position adjusted to your intended style of riding.

The name Esel is German for donkey, or rather ass, so if you use google translate on their (currently) German language-only website you will get some amusing labels to the My Esel gallery of their latest completed customer configurations , ie. photos of Lisa’s Ass, Katharina’s Ass & Tom’s Ass. But the 3.5-3.9kg (7.7-8.6lb) are no joke, and offer a level of customization that few production bike makers can replicate, from geometry to component spec.

Besides the adaptable wooden elements of the frame, the My Esel uses an aluminum headtube, an eccentric alloy bottom bracket, alloy seattube, and alloy rear dropouts that are each keyed into the wood frame.

The bikes get customizable finish too. The frames are built from ash veneer hardwood plywood and can get four layers of clearcoat to show the grain, with black or white painted finishes optional as well. A walnut veneer is apparently available as an upgrade, as is a dark black stain of the standard ash.

My Esel is working on programming their entire customization process so it is accessible directly through an online configurator on their website, but for now you can send them some basic preliminary information through their configuration page and they will work with you to get all of your crucial body measurements to craft a one-of-a-kind custom wooden bike tailored to you.

Complete custom My Esel bikes start at 3000€ and around 11-14kg (24-31lb), with their lightest builds getting down to 9.4kg (20.7lb) with some pretty high-end component selections. Bike builds are available with single speed drivetrains, internally geared hubs, or even e-bike motors to meet a wide range of user needs. While this isn’t likely to run the custom carbon framebuilders into the ground, it is nice to see people taking a different approach to building bikes, and it could be a great way to build a commuter bike unlike any other.