Now that we’ve outlined all Campagnolo has in store for us road disc fans, we can get a bit more into the details. The key detail here is that Campagnolo has developed a new set of hydraulic Ergopower shift/brake levers, fitting a modular master cylinder inside that does not impact the width or ergonomics of the lever body and works exactly the same with either EPS electronic or mechanical shifting mechanisms. For that reason Campagnolo chose to roll out the two shifting options in the new Ergopower levers under a new, non-series name H11 (hydraulic 11 speed) with carbon brake lever construction on par with the standard Super Record/Record rim brake levers. Paired with the H11 levers are an all-new set of flat mount, two-piece disc brake calipers that squeeze a specially developed brake pad to bring the 140 & 160mm round rotors to a stop – consistently, quietly, and with an adjustable level of force at the lever…

Campagnolo’s official company line has always been that they are first & foremost a road race company and their all of their components need to undergo pro race testing to truly be satisfied with their performance in that toughest of cycling environments. The problem was of course that the adoption of disc brakes in the pro peloton has been limited by a few vocal holdouts who were resistant to the new tech. In fact, the single rider who probably had the biggest impact in the whole affair was riding for a Campy sponsored team, leading some to postulate that the Italian company may have exerted some pressure to bide their time. Speaking with Campagnolo about their product development timeline and their attitude towards their pro riders, that couldn’t be much farther from the real story. Indeed while Campagnolo are late to the consumer side of the disc brake party, their pro teams have had fully developed Campy Tech Labs disc brakes at their disposal for more than two years. But since Campagnolo (unlike some of the other race sponsors in the pro peloton) doesn’t push new tech on their pros, they had taken a more laid back approach, supplying the teams with both rim brake gruppos, and disc brake groups which the teams have put through extensive testing out of competition.

While that has meant that the visibility of the project has been relatively low, Campy has been able to continue to press on in development with plenty of direct pro rider feedback. They haven’t been able to get the pro race testing they so desired, but felt compelled to continue to progress and committed to delivering a product that maintains their exceptional performance standard. That feedback has driven several design decisions and is one reason why they are able to introduce disc brake compatibility across so many groupsets immediately from launch.

Campagnolo tells us their disc brakes were actually finalized around this time last year, and they’ve benefitted from the extra time to make small refinements and continue to improve, expanding the offerings all the way down to their affordable performance Potenza 11 groupset which was introduced last year to replace Athena. That also let them spend more time on what they call Disc Brake 360° (DB360) which is essentially a wholly integrated approach staring with the new brakes and including everything from wheels (hubs, spokes & rims) to updated cranksets.

H11 mechanical Ergopower levers

Getting into the H11 Ergopower levers themselves in detail, we’ll start with the mechanical shift version, as that tends to be the one more limited by space constraints. But also because the H11 mechanical levers will be the first to market, available to customers within the next three weeks before the end of May 2017.

Campagnolo’s design intent was to retain the beloved ergonomics of their latest generation of Ergopower levers as much as possible, and they’ve done a remarkable job of keeping the same feel. While the visually hooked shape of the current rim brake levers is for the most part gone, Campy claims that the actual fit in your hands is 98% the same. And true enough the difference is for the most part visual. The lever retains the inward leaning thumb hook design of the rim brake Ergopowers, but now simply extends the outside edge straight up in a location where your fingers are reaching down in the other direction, in order to fit in the vertically oriented master cylinder.

Overall height of the hoods is just 8mm taller, a much smaller increase than we’ve seen from either SRAM Red’s tall square hoods or even the slimmed down levers of the latest Shimano Dura-Ace. One of the tricks of the H11 levers seems to be that the move to hydraulics enabled Campagnolo to significantly reduce the length of the brake lever blade above the lever pivot. This gave them more space to work inside of the lever body, but does give the impression of a taller hood from head on. On the other hand, from the riders point of view the difference is rather small, as you can feel in the hand.

While the slightly taller hood gets squared off, the width through the body of the lever at the bar remain untouched, as none of the new hydraulics are located there (much like SRAM). That means the hydraulics are completely out of the way of both mechanical & EPS shift guts, so lever feel in the hand claims to be completely the same as the rim brake predecessors.

One other small update to the fit of the H11 Ergopowers is a slightly updated brake lever blade. Campagnolo has flared the brake lever out a bit more at the tip in what they call the latest evolution of ergonomics for easier brake reach in the drops when mated with the current crop of slightly flared drop handlebars, while shift paddle stays in the same place. At first reach the lever shape feels familiar, but there is certainly a bit more blade to grab onto.

In a continuation of Campy’s ‘next level’ ergonomics the new H11 levers are much more customizable than their rim brake predecessors, much like we had assumed when they were first previewed last spring. The H11 hydraulic Ergopowers get a new acronym – AMS or adjustable modulation system – that lets riders adjust the leverage ratio of the braking system. Adjustable via the small 2.5mm allen key hole on the inside of the lever bodies, you pick either Short or Long throw to determine how powerful the braking action is. While this is not an adjustment of where or when the pads engage the rotor per se (like a specific free stroke adjustment) it essentially lets the rider tune how quickly the brakes move from open to full lock, so in effect does deliver a small amount of free stroke control. The difference in the two modes isn’t meant to be huge but it is noticeable and could be beneficial for riders who prefer a more powerful brake setup, or to the difference of riders on say 25mm vs. 30mm tires who have noticeably different tire contact patches.

In addition to AMS, the H11 levers also get independent adjustable lever reach through another small set of bolt holes, this time in the front of the brake lever for its reach adjust and from below to adjust the shift lever reach. These reach adjustments again do not impact free stroke, nor affect modulation, although riders can adjust the reaches when they adjust the AMS so the levers pull back to the same distance away from the handlebar at full lock.

Inside of the lever body is where the magic happens. Interestingly Campagnolo’s hydraulics team designed a single modular master cylinder that can be swapped to either left or right sides (it has a hydraulic fitting on both sides) and can be removed from the lever body itself. That’s very much a continuation of Campy’s theory of using rebuildable/serviceable parts in their groupset. But it also has the added benefit that the same single master cylinder can be used interchangeably in each of the different H11 Ergopower levers. For one thing that will make shop life a bit easier for mechanics, as well as reduce the number of spare parts to keep stocked. We didn’t have a chance to get inside and take the levers apart yet, but we’ll be curious to see more of their innards once they are available at the end of this month.

The master cylinder also incorporates a bleed port at the top dead center of the lever for ease of brake bleeding, so no more rotating the levers back and forth to shake air bubbles out like some of the competition. Inside the cylinder, hoses, and calipers you’ll find mineral oil operating the brakes. Campy says they’ll be selling their own branded oil, but mentioned that it was blue and being produced by manufacturing partner. They were leaving it up to us to infer that it will be the same or similar Royal Blood mineral oil that Magura sells.

That makes sense now that we know that Magura was Campagnolo’s development partner. There was much speculation early on about how Campagnolo would go about developing hydraulic brakes from the ground up with no experience in the field, and who they might partner with. It turns out that from the start of the disc brake project, Campagnolo did work with Magura essentially to bring them up to speed on developing hydraulics for road discs. For the most part that knowledge-sharing partnership ended earlier on in this project (although Campagnolo alluded to some continued involvement on the development of newer projects as well), and Campy assures us that all of the final engineering design for the H11 disc brakes was carried out by Campy’s own staff. The remaining hold out besides the blue mineral oil is a continued manufacturing partnership, where Magura is actually producing the master cylinders and brake calipers for Campagnolo, while Campy’s factories manufacture all of the remaining parts.

As for the shift internals, it seems nothing has changed for the H11 mechanical Ergopowers when compared to the current Record rim brake version. They still get the multiple shift functionality of Ultra-Shift with up to 5 position downshifting, and 4 position upshifting.

The H11 mechanical Ergopower levers are designed to work with 11 speed Super Record, Record & Chorus mechanical groupsets. It will be possible to get them as part of a complete group in the future at each level, or just purchase the H11 mechanical upgrade that pairs left & right Ergopowers separately paired with hoses and the brake caliper. The H11 mechanical Ergopower lever claim to weigh 698g for the pair including their caliper, and will retail for 495€* per lever/brake.

Complete disc brake groupset weights are claimed at 2228g for the 2879€ H11 setup with Super Record, 2260g for H11+Record at 2633€ & 2319 for H11+Chorus at 2343€.

H11 EPS Ergopower levers

Looking at the EPS version of the disc brakes, there is very little difference in tech or even look. Campagnolo stayed true to both maintaining the same fit & feel across the two versions of the H11 Ergopower bodies, as well as to carrying over the functionality of the current EPS groups to H11. The H11 EPS Ergopower levers use the same lower-profile thumb shift buttons of current EPS to deliver the same positive clicks to shift. The only other visual difference in the H11 EPS Ergopower levers are the use of the cutout shift lever design that only exists on Super Record EPS levers. It apparently sheds a gram or two, but also provides a slightly more tactile grip on the shift paddle.

Otherwise ergonomics are identical to the mechanical H11 Ergopowers with identical body shapes, only with slightly varied textures on the rubber hoods. They get the same slightly extended squared-off hood shape, the same modular master cylinder, same AMS power and lever reach adjustability, and the same flared carbon lever blades.

Campagnolo has announced that the H11 EPS Ergopower levers are being designed to work with 11 speed Super Record & Record electronic groupsets. We’re not entirely sure why they haven’t called out Chorus EPS, as it uses the same technology, so we imagine if you have a set of Chorus EPS derailleurs, you’ll still be able to control them by the new H11 EPS levers.

The H11 EPS Ergopower levers have one of the later scheduled availabilities of the new disc brake components, with delivery expected by the end of July 2017 for 553€ per lever/brake. At 596g for the pair of H11 EPS Ergopower levers including hoses and calipers you’ll save a little weight at the bar, which is then offset by the the battery and derailleur motors.

Claimed H11+Super Record EPS disc brake groupset weight is 2355g at 4397€, while going with a H11+Record EPS groupset should weigh a bit more at 2390g complete at 4063€.

H11 disc brake calipers

The H11 Ergopower levers are surely the brains of Campy’s disc brake solution, but they need a solid set of brake calipers to turn that adjustable, modulated power into actual brake force. Unlike the previous generation that we previewed last spring, Campagnolo seems to have put a lot more thought into these calipers two-piece, two-piston hydraulic disc brake calipers. First off they decided to go exclusively for flat mount brakes, and secondly the chose to ditch the adapters that pretty much every flat mount disc brake producer has been using.

Campagnolo was ultimately not satisfied with the developing a precision brake caliper and then having to bolt it to an adapter to secure it to the frame. The result is that the forged aluminum Campy H11 caliper eliminates both the flex/movement and additional risk of failure inherent in the adapter mounted solution.

The downside is that Campagnolo’s H11 brake calipers are specific to a certain rotor size. You can’t simply swap to a different rotor diameter by flipping the same caliper around on its mountain adapter. That would mean that Campagnolo would need to produce a different caliper front and rear for each rotor size, and multiply that by however many different levels of brakes the planned to produce.

They managed to keep that to just three calipers by doing two things. First Campagnolo sees road disc brakes as a clear improvement in safety, and after testing several different systems before they finalized their own design solution, Campy decided that the front brake rotor needed to be at least 160mm. So the H11 front brakes are 160mm only. Then in the back they recognize that some rider preference would allow either 140mm or 160mm rotors so they developed two direct flat mount calipers accordingly. Then to keep it to just those three calipers, ever groupset from Super Record EPS down to Potenza would share the same identical calipers.

To make the adapter-less design work though, Campy needed to come up with a solution to fit a wide range of fork & chainstay designs, so they worked out a two-bolt attachment system, offering bolts from 19-44mm long in 6 lengths that will fit all road disc frames currently on the market. The two-bolt solution also means that a rider can quickly and easily see both attachment points and more easily diagnose of one or more bolts is loose. The end result, increased brake system rigidity and thus less brake rub.

Inside the H11 calipers mineral oil from the levers pushes a pair of 22mm pistons to drive the pads up against the rotors. The pistons themselves are made of a fairly industry standard phenolic resin which effectively prevents heat resulting in extended braking from being conducted into the mineral oil brake fluid, limiting performance degradation from overheating.

Attached to those pistons, Campagnolo has included a set of magnets to ensure proper and even pad retraction. While the movement of the hydraulic fluid results in piston retraction, many disc brake pads require an external spring to push them against the piston and ensure retraction after braking. Campagnolo found that by using long life magnets they were able to deliver better pad clearance from the rotor over time, ensuring the 0.6mm pad retraction to maintain rotor clearance, as well as eliminate the possible interference of the typical metal spring.

Like the master cylinders in the H11 levers, the H11 brake calipers also include top mount bleed ports to make getting air out of the system simple and straight forward.

For now the H11 calipers are sold only bundled with their appropriate H11 levers, with the front brake including mounting bolts, while the rear brakes selling bike-specific bolt pairs separately for ~8-10€.

H11 disc brake pads

We keep stepping down to smaller and smaller components, but the tech runs deep here and Campagnolo has integrated a lot of unique solutions just into the brake pads alone. Of course brake pad:rotor interface is crucial for consistent powerful braking, so Campagnolo developed (and patented) their own unique organic resin pad compound & pad shape for the best balance of uniform & consistent stopping performance.

Looking at the shaping of the braking material on the pad, it is also clear that Campagnolo thought about how to speed rotor alignment & wheel installation. By the simple chamfering of the brake pad’s edge, it should be easier to line up your rotor and axles to quickly reinstall a wheel on the go (or in a race situation.)

But most notable in the disc brake pads design is the unique application of technology developed in motorsports to reduce vibration and noise against the rotor. Campy has developed in-house a special laminate material that sits between the brake piston and the metal pad carrier (that holds the organic brake pad compound). The laminate isolates vibration between the two – damped to much lower levels – with the promise of virtually eliminating brake squealing, and a side benefit of offering an additional layer of isolation from heat transfer from rotor to brake fluid. The anti-noise laminate is both glued & mechanically fixed to the pad carrier so is said to outlast the braking material itself. The small metal clips bent around the pad carrier also apparently offering an audible pad wear indicator.

H11 disc rotors

The last core element of the Campagnolo H11 disc brake project are the brake rotors. For reasons we discussed above, Campy decided to produce both 140mm & 160mm rotors, although only to use the smaller rotor in the rear. They also chose to use a stainless steel braking surface construction pinned to an aluminum carrier – 6 arms for 140mm rotors, 7 arms on 160s. This was said to offer the best balance of weight and heat management with the most consistent, safe, and linear heat dissipation. Campagnolo was rather open that they had tested several alloy braking surfaces and seen that they just wouldn’t survive the most extreme braking conditions.

Campy opted for what they are calling the AFS standard rotor interface (that’s Axial Fixing System, or the technical term for competitor Shimano’s Centerlock design) as that seems to be the way most performance disc brake wheels are going and offers a secure rotor interface.

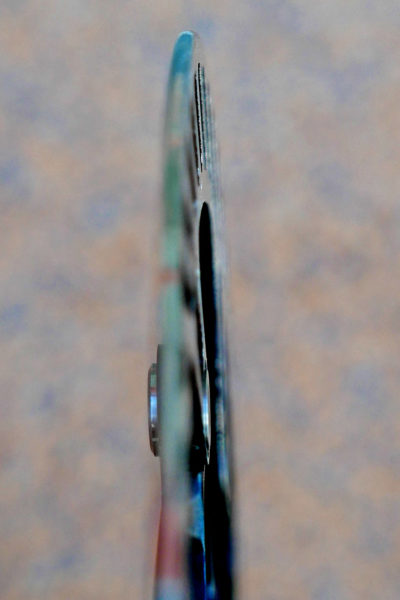

With regards to safety, again Campagnolo was adamant about the priority they put both on real and perceived rider comfort with the new technology of disc brakes. They developed a rotor design with a smooth, continuously round circumference as it would be the least likely to inflict injury to riders in a peloton (as opposed to what they called the sawtooth designs prevalent in the mountain bike industry.) Outside of trail riding on excessively muddy roads & tracks, they also didn’t see any pad clearing performance to the sweep-style rotor shapes over their own perforated design.

The 1.85mm thick rotors then get a very smooth, machine rounded profile to the outer edge (much more rounded than the more chamfered solution we saw from Shimano back in January) making them as innocuous as physically possible. With a functional wear limit down to 1.65mm, the same H11 rotors are shared across all Campagnolo disc brake group sets and will sell for 50€ in either size.

More tech details coming…

We won’t overlook the fact that Campagnolo are adding disc brake specific cranksets as well. While it sounds absurd at first mention – seriously a disc brake only crank?! – Campagnolo is correct that by moving to 5mm wider rear hub spacing in the move to road discs, shift alignment would be compromised, especially with ultra short chainstays. We saw the same progression with Boost on mountain bikes, and it’s probably about time someone addressed the concern on the road too where the impact is potentially greater due to shorter rear end designs.

Of course Campagnolo who pioneered the race-ready, system-built wheel concept more than two decades ago isn’t going to make the jump to road disc brakes without having new wheels in the works too. So they have introduced three carbon and one premium alloy disc brake wheelset that should meet the needs of most cyclists wishing to make the leap to Campy discs.

We’ll keep digging deep into those topics and more. Keep abreast of all of our coverage of the new Campagnolo disc brake groupsets here:

- Campagnolo road hydraulic disc brakes overview

- Potenza 11’s alloy disc brake solution

- Disc-specific cranksets

- Shamal Ultra alloy 2-Way Fit tubeless disc brake wheels

- Bora One carbon tubular & clincher disc brake wheels

- Campy H11 mechanical long-term review

*note: Euro pricing does include VAT. The previous reference to the exclusion of VAT was incorrect. We apologize for any confusion.