We headed to DT Swiss’s headquarters in Biel/Bienne, Switzerland to take a look at how they still make tons of spokes, plus some rims & complete wheel builds in the heart of Europe. Situated at the foot of the Jura Mountains on the northwestern edge of the Alps, DT’s Swiss HQ houses both their main product development offices, as well as a modern manufacturing setup nestled in between factories crafting some of the world’s premier watches (think Rolex, Omega, Festina, even Swatch). It’s not a bad place to ride either, with the nearby Mon Chasseral climb making for a good place to test the road wheels of the same name. Back at the factory DT gave us a look at how they prototype new wheels, produce smaller batches of aluminum rims & complete wheels for special runs in their Biel Performance Manufacturing shop, and forge an unbelievably large number of spokes. Take a look inside the factory with us…

Aluminum rims

With regards to rim production, DT Swiss doesn’t do too much in the small factory floor attached to their Biel/Bienne HQ. The majority of wheel and rim production is now handled by facilities in Poland and Taiwan, for the most part geographically depending on whether the products are destined for aftermarket or OEM sales, respectively.

With that said, DT does develop all of their aluminum rim profiles in Switzerland and use their factory floor to test new tooling and dial-in production methods that they then push out to other factories.

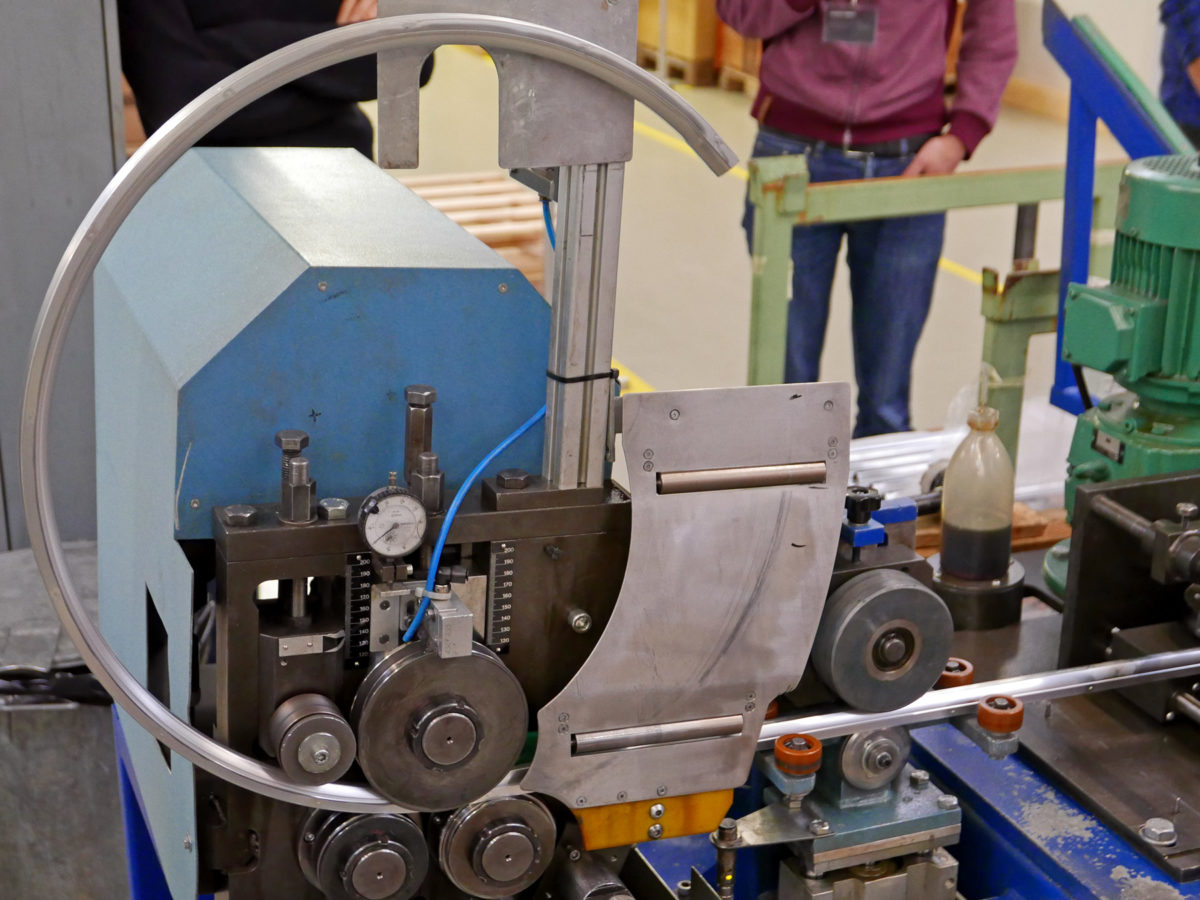

That means DT has the capability at HQ to take aluminum profile stock, extruded just across the border in Germany, and turn it into rims. The process is interesting to watch as tools are set up to coil the extrusions into the correct diameter, getting three 700c rims out of one original 6m long profile.

A pre-set saw them trims the coil of rims to correct length, and they are ready to head to the next step.

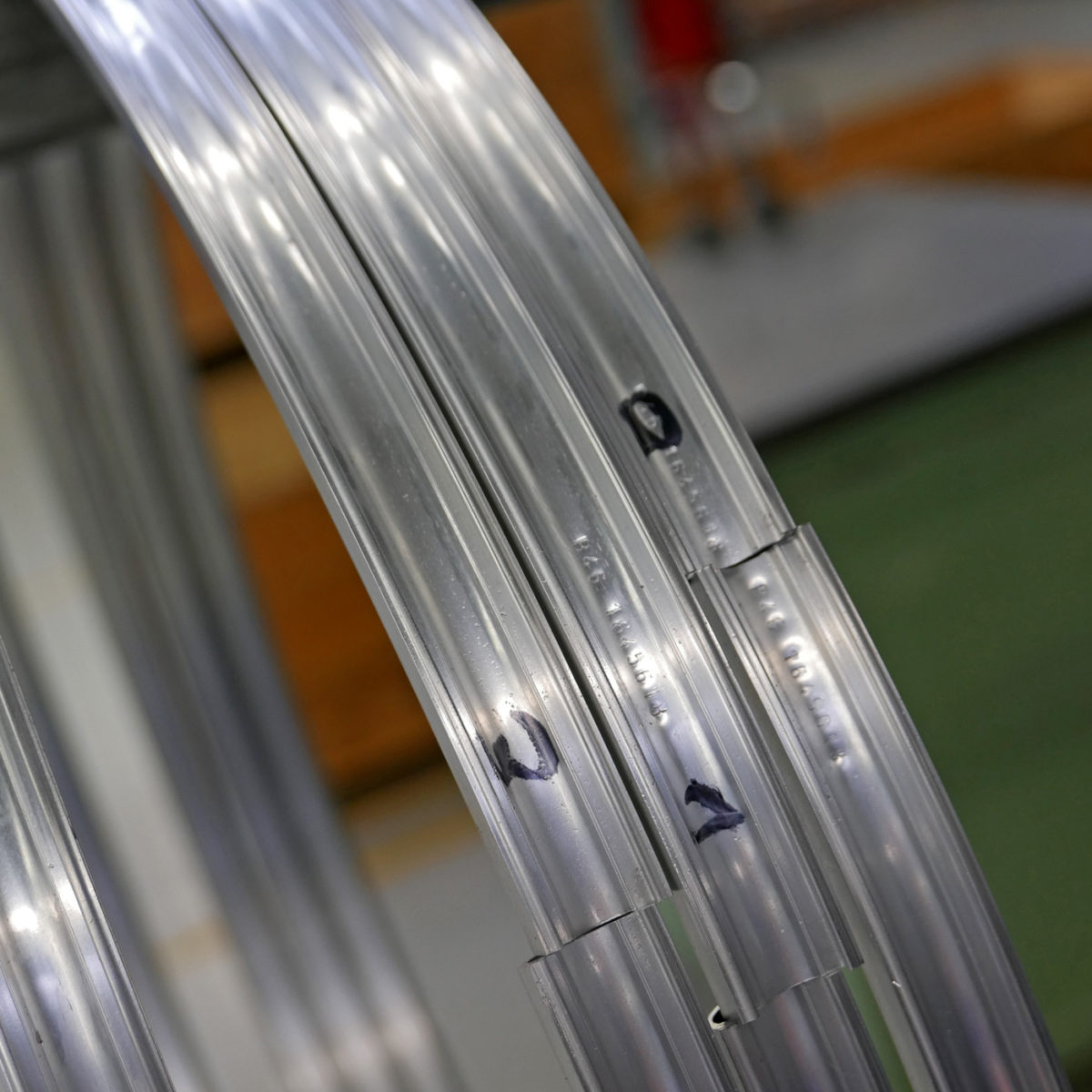

DT Swiss welds the vast majority of their aluminum rims to ensure a stronger build and better braking. But first – like these RR440 rims – they get a pressed-in alloy insert that does double duty of supporting the joint as it is welded and offsetting the weight of the valve on the opposite side of the complete wheel for balance when spinning at high speed.

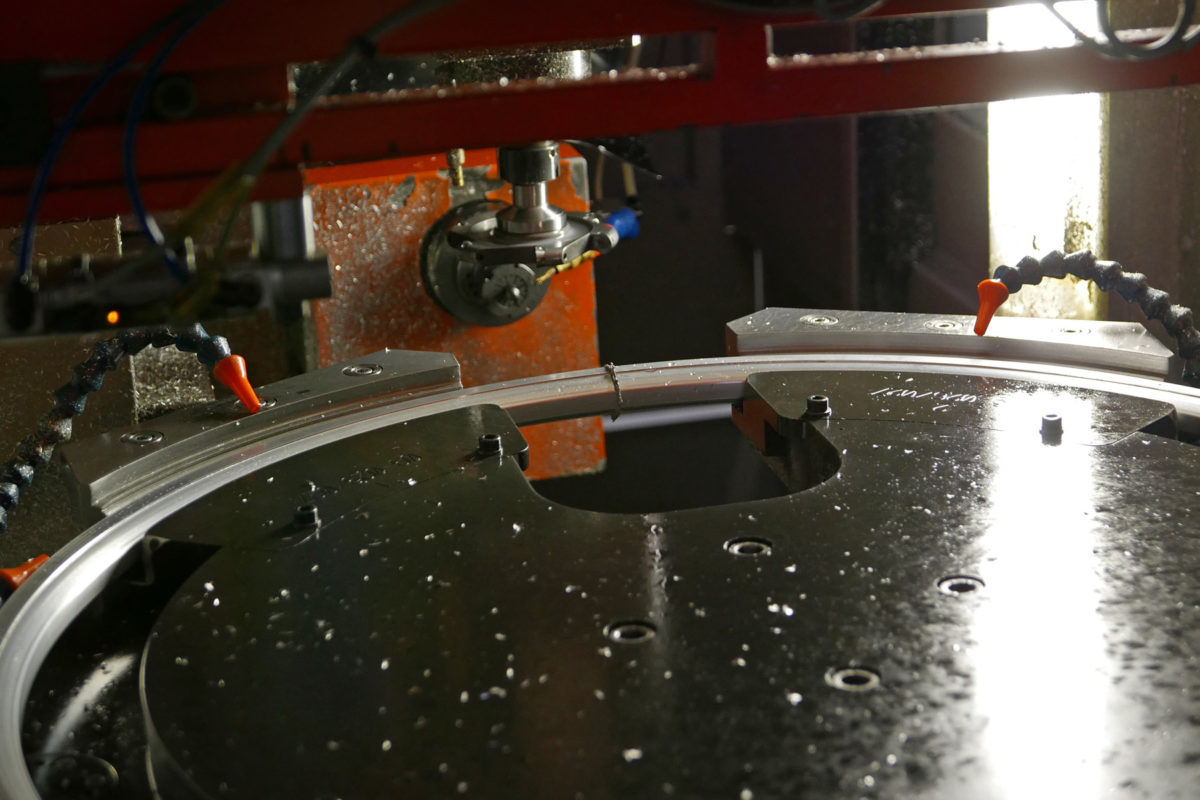

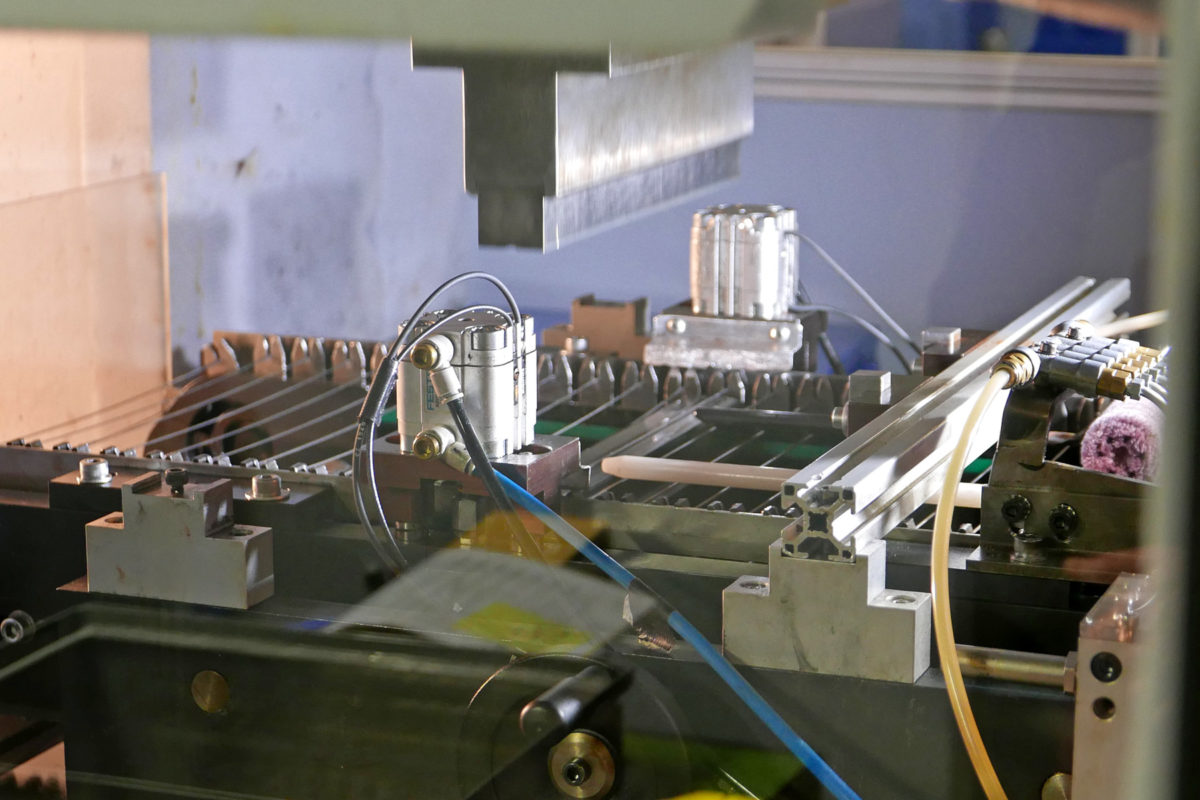

A specially set up machine clamps the rim to tight tolerance and precisely welds the thin rim profile from all sides evenly.

Then into the next machine that uses a shaper blade to knock off the majority of the weld along the inside of the rim bed, as well as a first go on the brake track and around the outside of the profile. It will next go into a grinder that will smooth down the exterior even more.

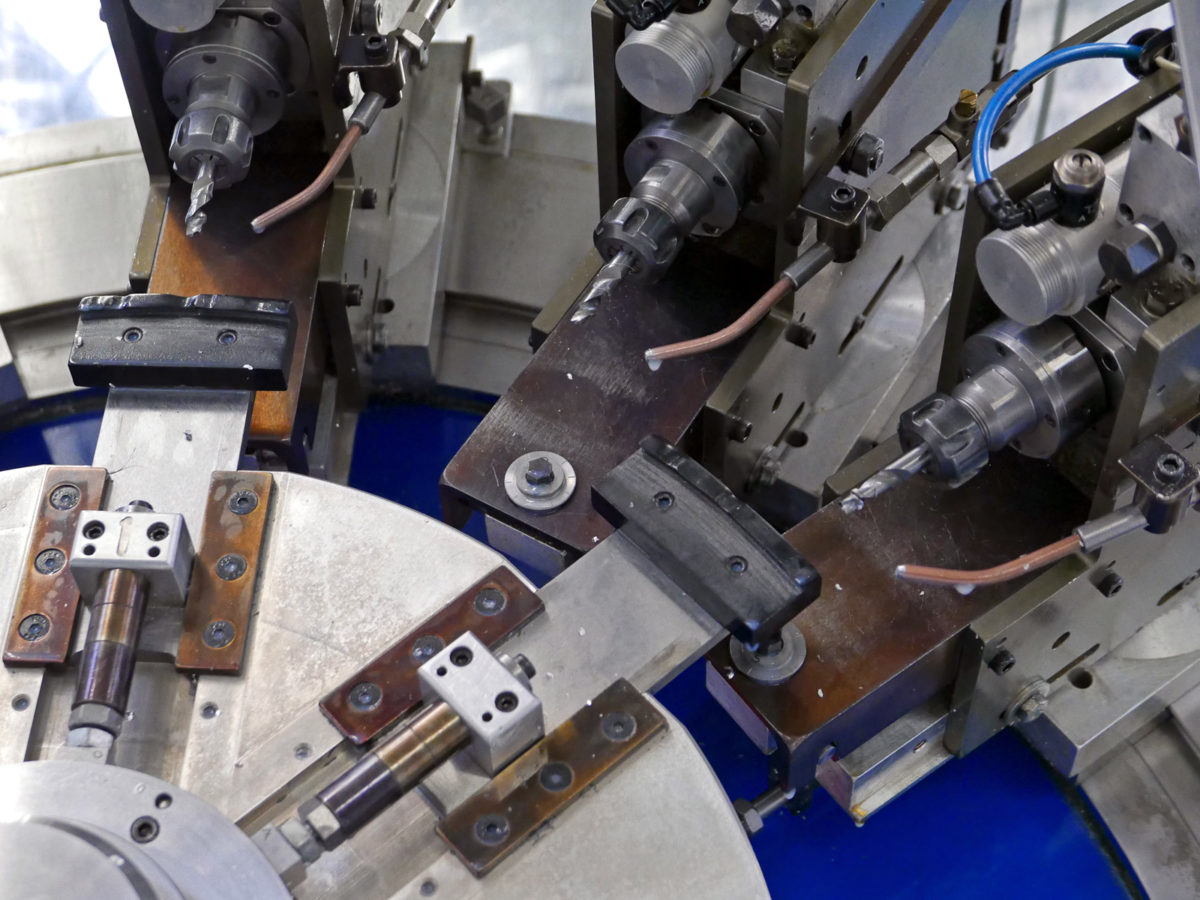

Then into the spoke hole drill rig that can be setup for any drilling pattern they want. These RR440s are destined for 32 spoke holes, so the machine is set to drill 8 holes at a time. It then is programmed to rotate three times to finish out the rims’ holes. The modular layout means just tighter turning and an extra rotation to deliver 36 holes, or reconfiguration of the drills for 28 holes. To keep everything moving fast, the rim hole machine uses tapered drill bits that give the proper size holes for both inner & outer walls of this RR440 and its spoke hole eyelets.

Then out of the drill and it is off to deburring, quality control, then off to be anodized black. The rim then comes back to the floor where it also has its brake track machined and rim wear indicators machined in. Then, over to the press for eyelets and graphics before going into a wheelset.

All the aluminum shaping creates a lot of scraps to be recycled. That’s where old technology comes in. It’s hard to beat the efficiency of a pitchfork, whether for hay or aluminum shavings.

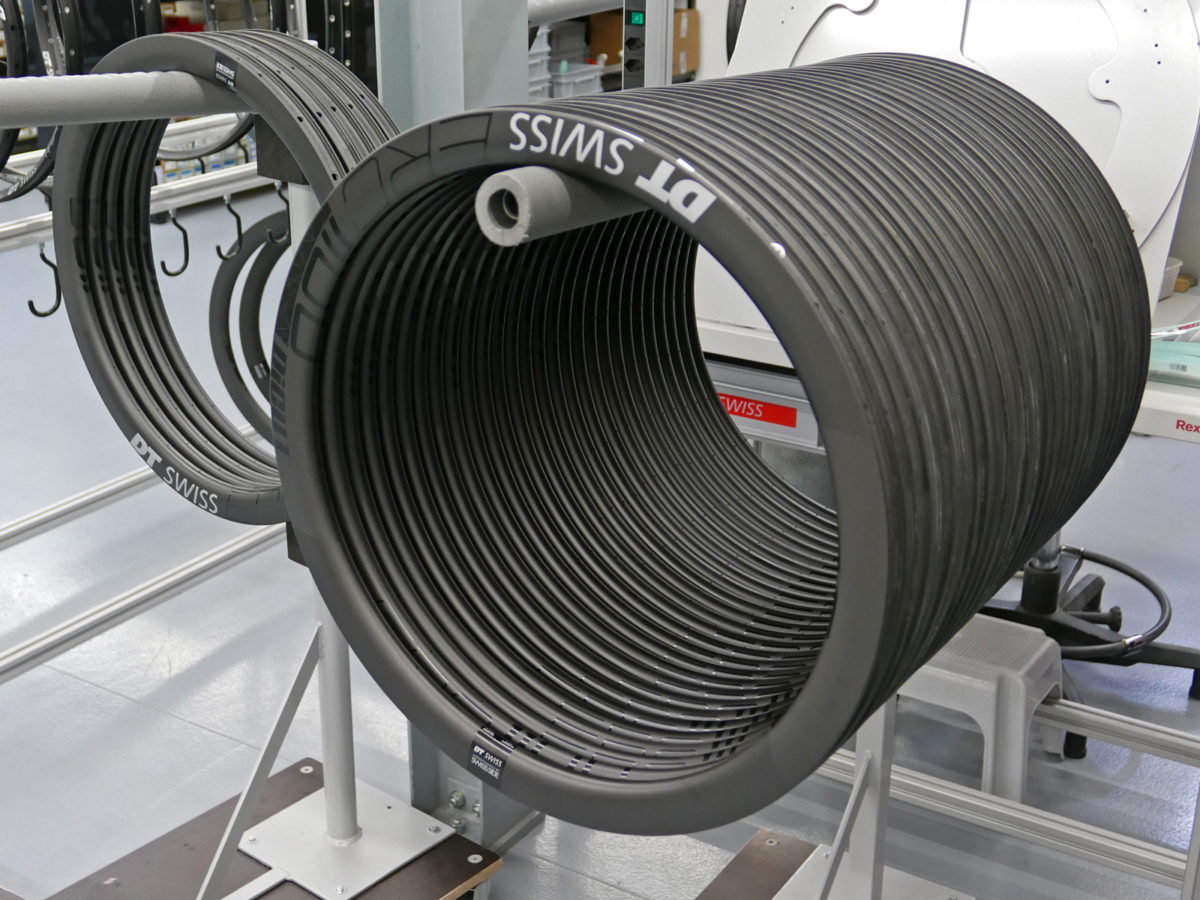

Once the rims are complete, they get hung up like these TK540s to be built into wheels or crated up to be shipped off to wheel builders. While the small rim production line in Biel is used mostly for dialing in the production process for their other manufacturing facilities, DT can also use its flexibility to more quickly produce a low volume run of a rim profile that is needed outside of their regular big production schedule.

Stainless steel spokes

While rim production has moved elsewhere, huge numbers of spokes are still produced in Switzerland. That’s where the company got its start as a wireworks (Drahtwerke/Tréfileries in both their native German & French) back sometime in the mid 1600s making fence wire, and eventually bicycle spokes around the early 20th century. In its modern form since 1994 spokes have been the first core product.

Between this facility and a similar one in Grand Junction, CO DT Swiss produces the vast majority of their several million spokes each year – from the basic straight gauge Champions to the advanced, double-butted Revolutions and bladed Aerolite families. No matter what the spoke is going to become, it starts its life as a coil of stainless steel wire, mostly from Italy & Sweden according to the labels we saw on these spools.

The wire gets pulled off the spool like thread, as a spoke machine continuously draws it the wire in, through a long line of opposing rollers that pull it tight (without stretching the steel), and straighten it out. Then the tool cuts each spoke to length and stamps a head onto it, and gives it a J-bend if needed.

As each spoke rolls out of the augers that pull it through the machine, tooling cuts the threads into one end…

…before ejecting them out the other end, at a rate of about one spoke per second, per spoke machine.

With a half dozen or so machines pulling straight gauge spokes out at a time, they add up really fast, and there were stacks-upon-stacks of these straight spokes waiting for what’s next.

For the more basic bladed spokes like the Aero Speed or New Aero, the next step is a set of cold forging presses that stamp the straight round spoke. One at a time an automated conveyor lifts each spoke into place and draws it into the machine.

There a die slams down onto each spoke, one-by-one with up to 500 tons of force, pressing it into a second die to give it a flat bladed profile, before being carried out the other side.

Again one at a time, the spoke makes its way into the next stack, with machine operators running quality control on the go.

Of course many of DT Swiss’ spokes are a bit more advanced. Instead of just getting cut to length and threaded, their Competition & Aerolite family get butted right from the start. DT is very protective of this proprietary process, and keep these machines out of reach of our camera. Instead of stretching the spokes to get the thinner middle profile like some companies do, DT Swiss forges this middle section to create a stronger spoke but not impacting its weight. DT was cagey with the details, but essentially they use a system of small hammers inside those brown boxes that compress the shaft of the spokes as they make their way through the machines in a process that appears to require a complex system of hydraulic cooling to keep it running smoothly, and takes about 10 seconds per spoke.

Once butted, the straight spokes all make their way back to machines to stamp a head on them, whether J-bend or straight pull, and to get threads cut in. Then they might make their way back out to the main cold forges, where they can get stamped into a flattened aero profile. The result is that starting with a similar material, it takes more then 11x as long to produce a Competition spoke as it does a Champion.

Some spokes stay silver. Others get taken aside for a black finish. Then it’s off to be boxed. Small numbers of spokes can be hand counted, but when you are packing stacks of boxes of 100 spokes each, a precise scale is the best way to get the count right.

Then they are ready to go to a wide range of industry manufacturers that build their own wheels with DT Swiss spokes. Or it’s off to DT’s own wheel building…

BPM wheel building

DT Swiss has a premier wheel building shop set up between the factory floor and their design offices. Dubbed the Biel Performance Manufacturing shop, this is the wheel building lab where DT refines their production building techniques. It is also where they build all of the wheels for sponsored riders. So those #GoldStandard DT Wheels that we saw World Champion Nino Schurter ride to wins in the last two weekends of World Cups on his Scott were built by the team here in Switzerland.

The BPM shop is where DT is able to build up prototypes, and to experiment with different rim, spoke, nipple & hub combinations as they develop new products. Working completely with their own components to build wheels is something a very select few companies can reproduce.

DT develops production methods at BPM, like their recent move more to the light & durable water slide decals we’ve seen replacing decals on their high-end wheels.

It is also where they build new carbon rim profiles into wheelsets before production is up and running at their EU factory. It also is in most instances, where wheels that we at Bikerumor test, come from. But that’s not to say that production quality is more advanced or higher quality than their production factories. It is more that this is where the first wheelsets for each new product are built, as they figure out in-house how to optimize their mass production with the same equipment in those other facilities. In fact the exact same Swiss machines that they develop here are sent out to each of their wheel building facilities.

This is where the first sets of aero disc brake Dicut hubs were first laced up, and the first facility to work out how to use these new spokes. Now found on their ERC1100 aero endurance wheels and the upcoming ARC1100 all-out aero road wheels, the new T-head straight pull spoke actually speeds up wheel building as they hold the spoke at the hub, perfectly aligned and kept from rotating. Developed in the BPM lab, the spokes also allow for a more narrow, more aero hub shell flange. Developed here, in the case of the ERC wheels, the spokes get a round profile near the hub and blading towards the rim in what DT is calling a 2/3 Aerolite design that gives the smooth ride of a round butted spoke and the aero performance of a fully bladed spoke.

With a stock of all types of DT components to choose from, the BPM group produces around 200 wheels a week out of this lab. That isn’t going to eat into their total production numbers, but ~10,000 wheels a year isn’t a number to scoff at.

The key to the facility though is really optimizing how they build each new wheelset. Down to custom jigs to lace any new wheel they develop, (held in place by RWS levers of course). BPM figures it out, so production in Taiwan & Poland can run full speed.

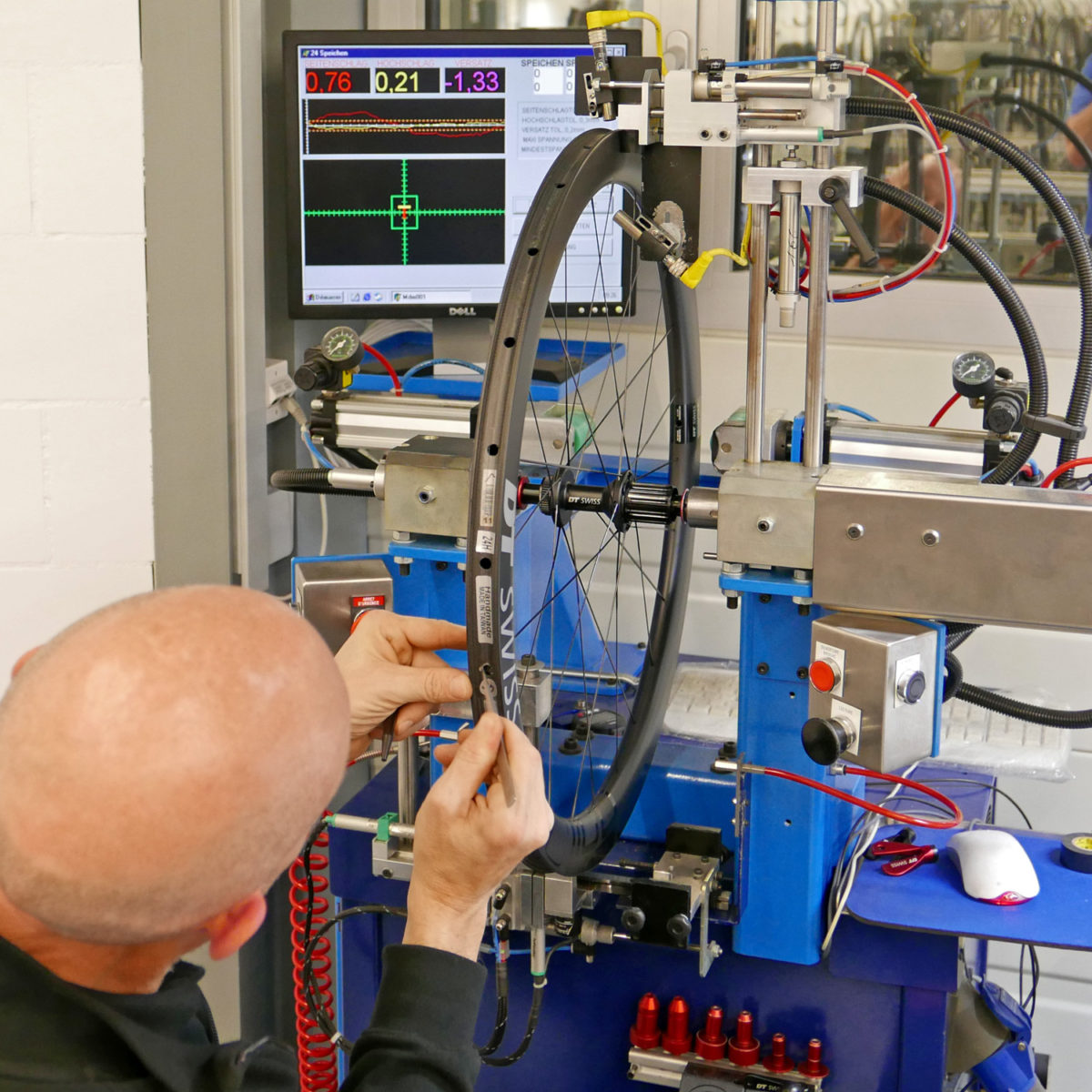

Whether that means developing computer controlled systems for tensioning & truing wheels…

…or building them by hand, BPM irons out the processes and methods that get transferred into DT’s serial production.

Marcel Waldmann leads the BPM group and he gave us a run through their capabilities, flying through a premium wheel build like only a master builder could. As he put it, of course it doesn’t hurt to have the best tools in the world at your finger tips.

I always end up pressing a hub shell against the workbench or floor to even out tension on my wheelbuilds, but Waldmann has a hydraulic tool for that. A bit more precise, and controlled.

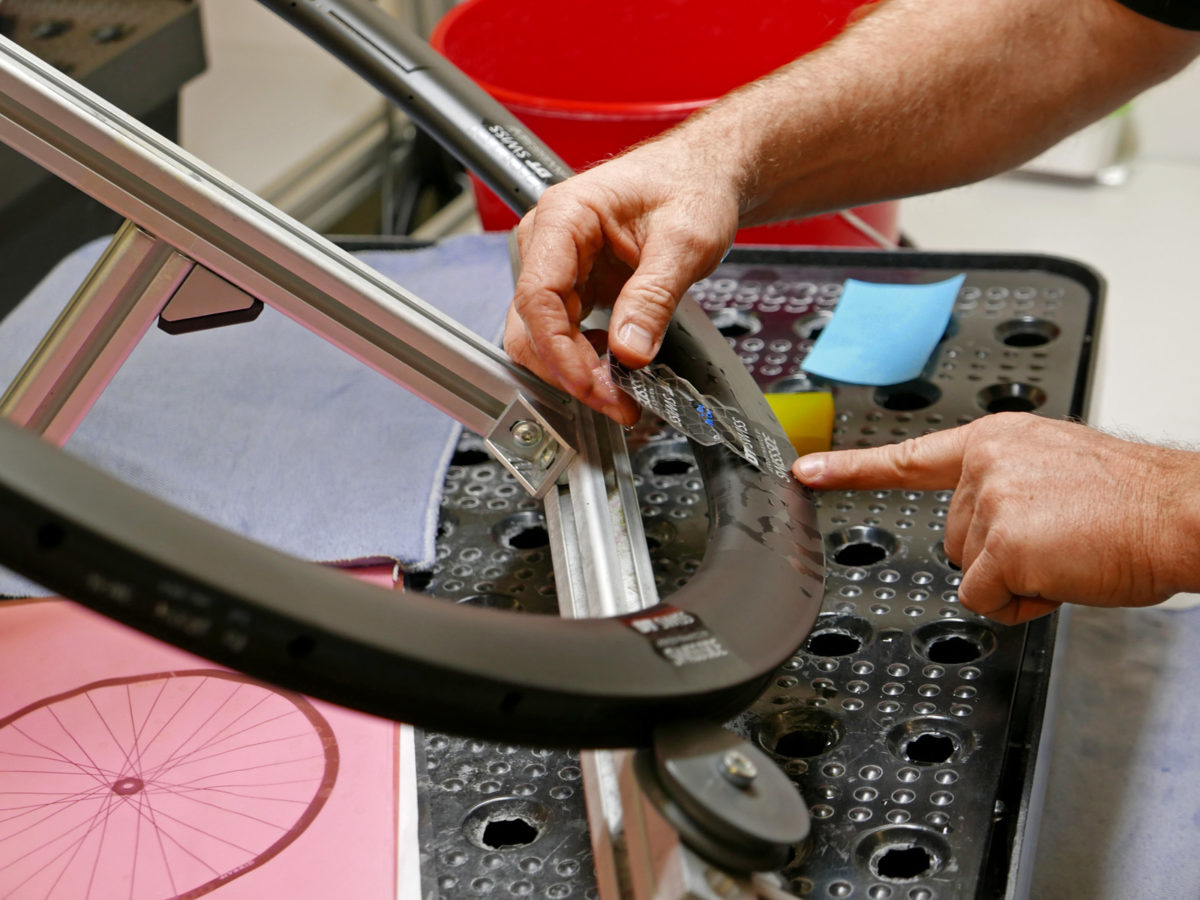

At each step of the way Waldmann and his BPM team refine tooling to ease and speed up reliable production. That has meant developing a custom dishing tool that works as well when the wheel is in or out of a truing stand. That also means a connected set of gauges that not only measures how round and true each wheel they produce is, but logs the data to track every wheel build characteristic to the unique code of the wheel.

Individual tension meters for non and driveside spokes allow DT to more precisely measure tension due to the variation from one side to the other.

And of course all that data is logged in to the spreadsheet for each wheel automatically via the connected measurement devices. The wheel builders can immediately see any characteristic that is out of tolerance range, to figure out how to go back and correct it as needed, and avoid it in the future.

Lastly it comes down to finishing. All of DT Swiss’ modern wheelsets are tubeless ready, whether with carbon or aluminum rims, so even a precise rim taping station is key to make sure every wheel leaves their production facilities ready to ride. And of course it doesn’t hurt to have your wheels built by someone who has a race pedigree to match his wheel building prowess. BPM group leader Marcel Waldmann just happens to be an ex DH Masters World Champion from a few years back. So I guess World Champ Nino Schurter probably had another World Champ build his race wheels.