It’s taken three years of development, more than 10,000 design iterations, and complex FEA, CFD, and wind tunnel testing, but the newest additions to the Bontrager wheel family look like they may have been worth the wait. Fresh off the Bontrager workbench is the Aeolus XXX carbon – in three completely different depths and shapes. Not only are the rims wider and tubeless compatible, but the rim brake models also tackle the Achilles heel of carbon – brake tracks. Bontrager claims their new Laser Control Track is on par with braking from alloy rims, giving you the confidence to push it harder through the corners.

Aeolus XXX breakdown

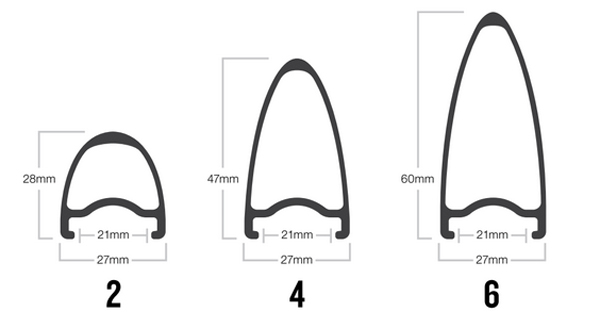

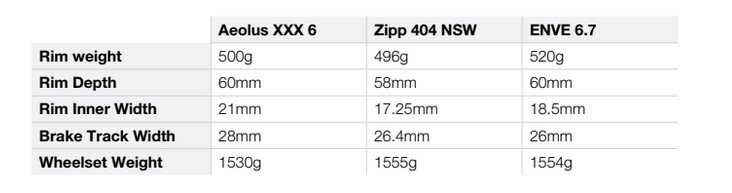

Built with Bontrager’s OCLV XXX carbon, Trek says that “All Aeolus XXX wheels are designed and domestically manufactured at Trek’s Global Headquarters in Waterloo, WI, USA.” Using a profile that is fine tuned for each depth and use case, the rims all feature a 21mm internal rim width that converts to tubeless with a Bontrager TLR strip.

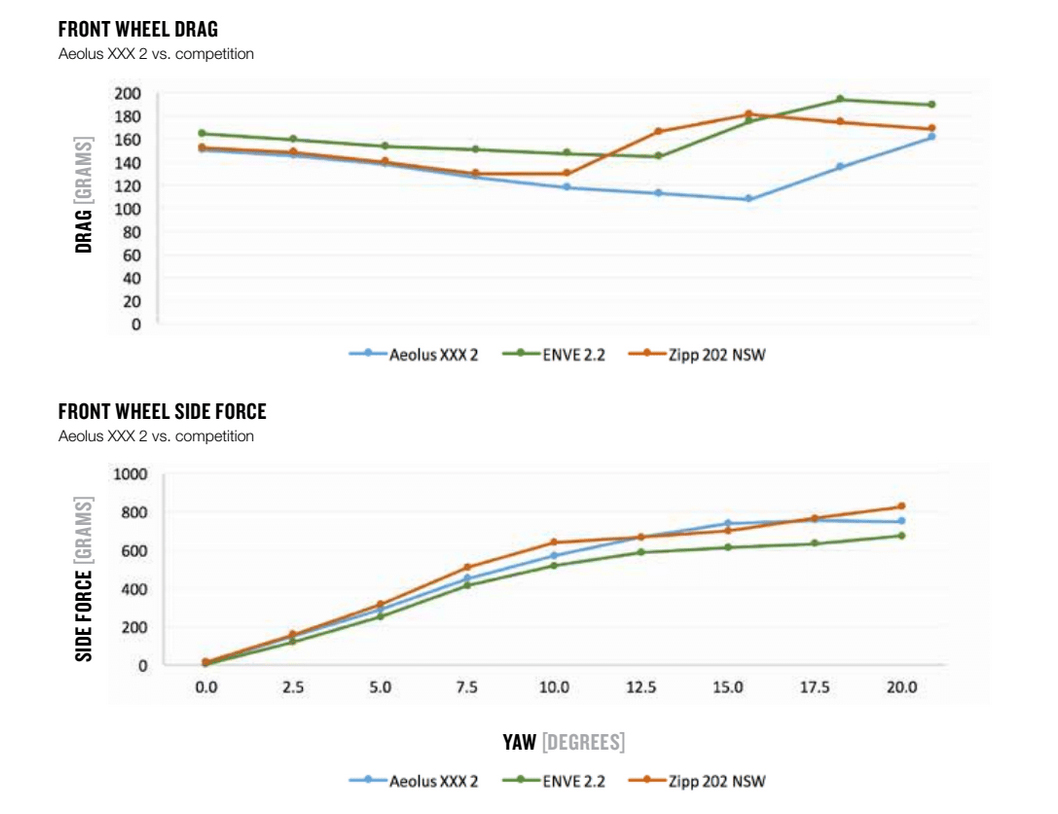

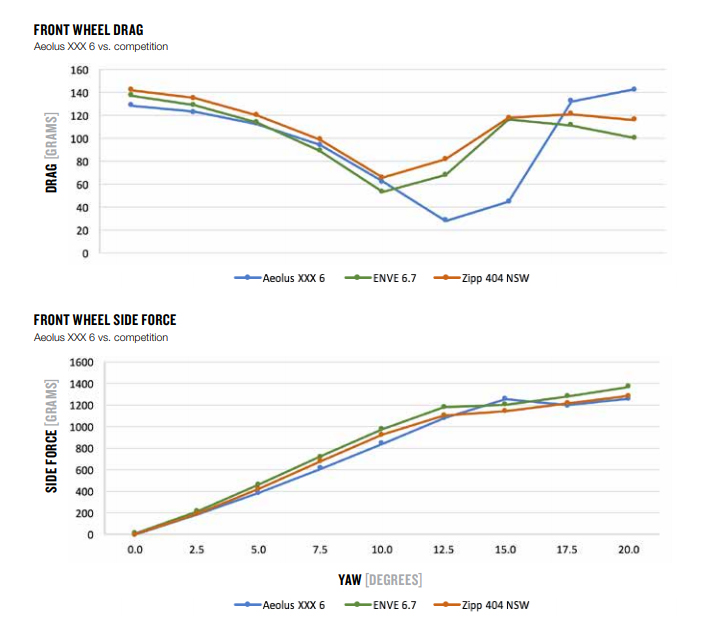

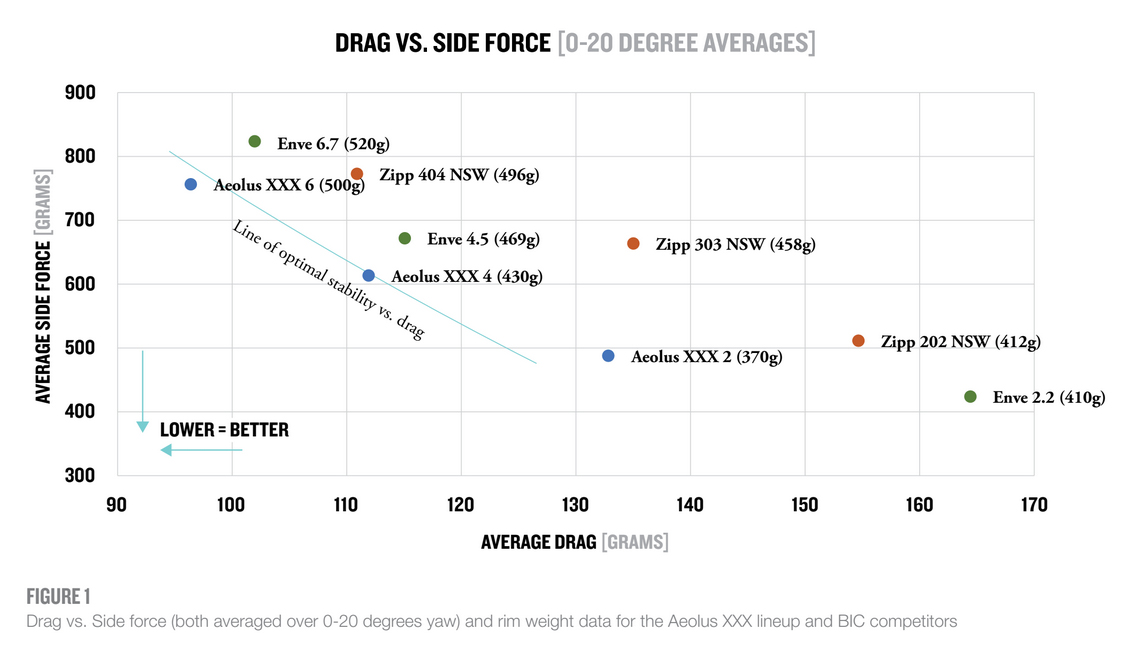

We’re used to manufacturers making claims that their wheels are the fastest or best, so it always has to be viewed with some scrutiny, but at least in this case Bontrager has a 34 page white paper to back up their claims. Long story short, in addition to trying to make the most aerodynamic wheels, Bontrager also placed a large focus on building the lightest, and most stable wheels as well. If an aero wheel is fast in a straight line but the instability caused by high side forces makes it a handful to ride, you’re not going to reach for that deeper wheel when as often as you could. This is another story line that we’ve heard before, but it’s one that Bontrager really pursued.

Through an intense combination of CAD design, Finite Element Analysis, Computational Fluid Dynamics, optimization with Red Cedar Technology’s HEEDS software, and prototyping, and wind tunnel testing, Bontrager lays claim that these are the best wheels available (there were also wind speed and yaw measurement sensors involved as well). Settling on three distinct profiles, Bontrager says the rim shapes and even the process are patent pending.

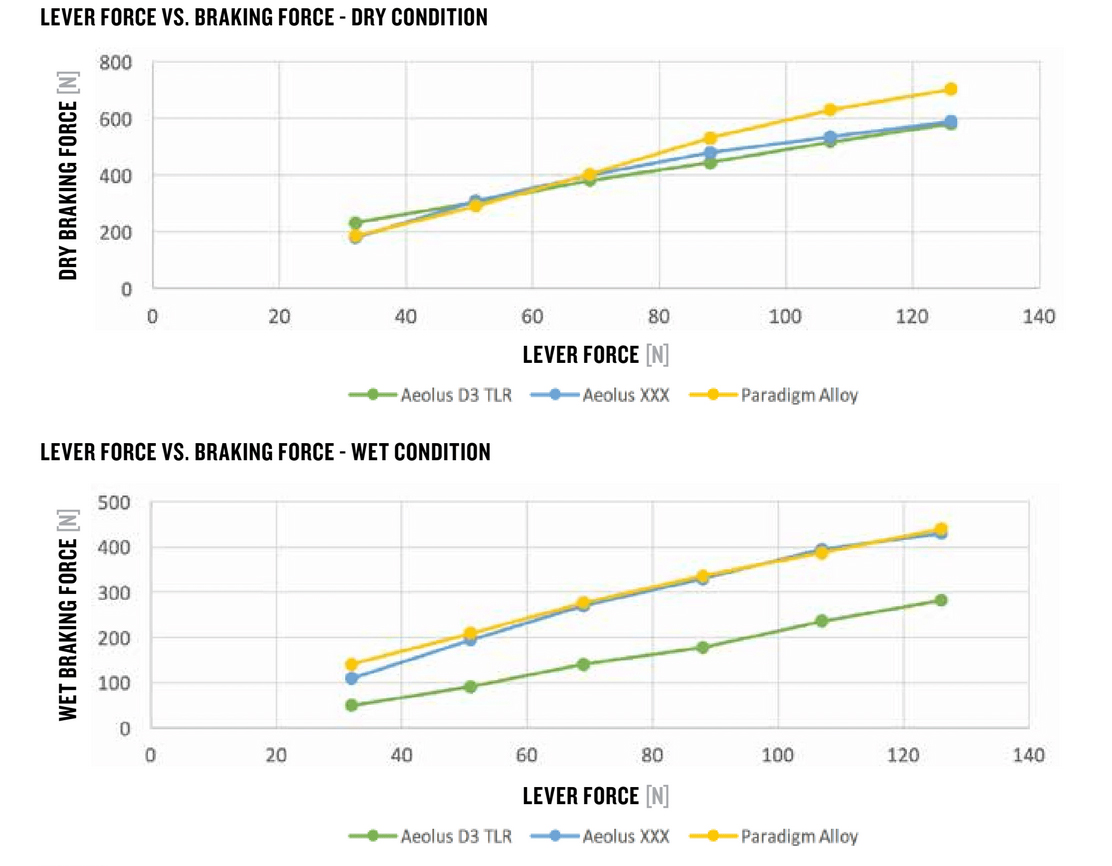

When it comes to braking, the rim brake models use a new brake track with a laser etched texture to improve braking performance in all conditions – but especially in the wet.

Combined with the Swissstop Black Prince brake pads, Bontrager claims braking close to that of an alloy rim. If true, that’s quite an improvement over many carbon rims.

Built with Bontrager straight pull hubs, rim brake models have quick release hubs spaced at 100mm up front and 130mm in the rear. Spacing for disc brake hubs is 100mm front and 142mm rear with 12mm thru axles. DT Swiss freehub internals are found as usual, and get 36 points of engagement. Freehubs are 11speed cassette compatible.

From gravel to pavement and everything between

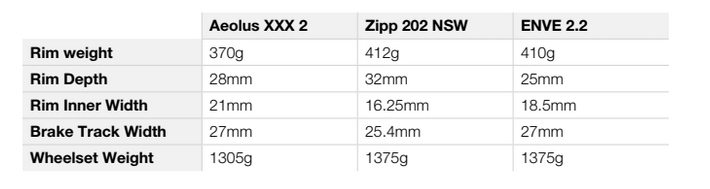

Light enough to be a climbing wheelset but strong enough for cross and gravel, the Aeolus 2 wheels have 28mm rim depths and come in disc and rim brake options. The disc brake set get 24 spokes both front and back while all other Aeolus wheels have 18 spokes front and 24 rear. Weights for the disc brake option include 630g front and 750g rear for a set total of 1380g. Rim brake weights are 580g front and 725g rear totaling 1305g.

On the pavement

If you’re looking for a more road-specific wheel, there’s the Aeolus 4 & 6. The 4 gets a 47mm rim depth and weighs in at 630g up front and 750g for the rear for a 1380g total. Like Easton, Bontrager uses the term everyday aero. No, that doesn’t mean you should buy a set for your commuter – rather it’s an aero wheel that you could use on nearly ride whether a climbing day or fast day on the flats.

Compared to the 6 that measures in at 60mm and weighs 630g for the front and 770g in the rear totaling 1400g. This is the “ultra-aero” wheel in the group and is fast but still offers a comparatively low side force through most of the yaw angles.

Check out our follow up post where we review the Aeolus XXX 4’s actual weights, widths, and first impressions.