After a bit of a hiatus, Noble Bikes used Sea Otter 2018 to re-launch the brand with gravel, cross, and even a full suspension mountain bike. That mountain bike was one of the bigger parts of the story as it included a new “standard” called Flat Mount 180. Co-developed with Mark Landsaat, UCC, Magura, Tektro, TRP, and Promax brakes, Flat Mount 180 is technically a new standard, but it’s one that doesn’t really use any new parts. SOC18: Noble Bikes re-launch along with new Flat Mount 180 brake standard

For the brake companies involved, creating a brake for FM180 is as simple as attaching a flat mount road caliper to a mountain bike lever. This works since their MTB and road brake systems use the same ratios for how much fluid is pushed from the lever. And since this is for the rear brake in XC/trail applications, a two piston caliper with a 180mm rotor should be plenty powerful.

Why do it in the first place? Mark points out a number of reasons. First, the standard is easier to manufacture since the threads are in the caliper rather than the frame. Because of that, if you some how manage to damage the threads, you’re only replacing a rear caliper rather than the whole swingarm or frame. Since the caliper is lower profile without any adapters, the calipers can be tucked into the rear triangle even with 180mm rotors. While the original design is for 180mm rotors, Mark also has drawing for FM160 which is essentially the exact same thing but with the caliper positioned for 160mm rotors.

FM180 is an open standard that Mark has made free for anyone to use, and technical drawings and dimensions can be found at flatmount180.org. Currently, only the four brake companies mentioned are officially on board, but Mark mentioned that while SRAM and Shimano brakes would work, neither company currently endorses their use for FM180.

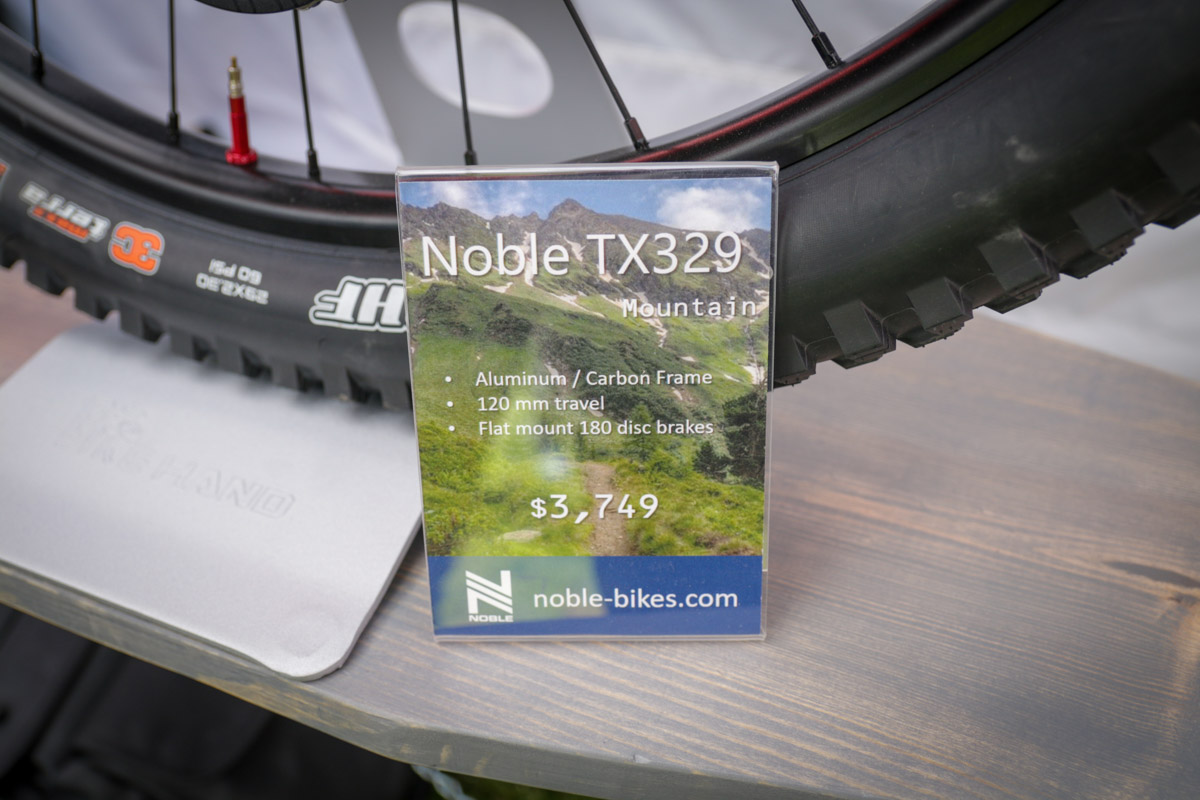

FM180 made its debut on the new Nobel TX329 mountain bike. If the design looks familiar (like maybe the Raleigh Skarn), that’s because it is – Mark used to be the Director of Product Development for Raleigh bikes and was responsible for the Skarn’s design. Now, the TX329 has a very similar suspension system with 120mm of travel and 29″ wheels. Noble will also offer the frame design with 27.5″ wheels and 130mm of travel, both bikes with a 6000 series aluminum frame other than the carbon seat stay. One thing Mark has always believed in is a low leverage ratio on the rear suspension which is why the frames have a longer stroke for the shorter travel.

Built with internal routing, Noble bikes have a clever port on the downtube which help aim the cables as they exit the frame. Mark says he plans to upload the printing files for these pieces to Shapeways.com so that if you ever lose or break one, you can simply use a 3D printer to create another one.

Available mid to late 2018, the Noble TX327 will be sold for an impressively low $3,749 complete in either 27.5 or 29″ wheels.

On the dropbar side, Noble will have two new gravel bikes with the top end filled out with the GX5 carbon. The GX5 includes 700c x 40mm tires and a SRAM Force 1 drivetrain, carbon fork, and flat mount 160 brakes for $2,999.

The GX3 is mostly the same except in aluminum rather than carbon. It still features internal cable routing with the downtube port, a PF86 thread together bottom bracket, and 12mm thru axles front and rear. This time it features a SRAM Rival 1x drivetrain for $1,999. Both bikes have what Mark refers to as Forward Geometry which features longer top tubes paired with shorter stems for improved handling.

Then there’s the CX3 which is the cyclocross equivalent of the GX3. Built around 700c x 33mm tires, the CX3 is geared towards CX racing and includes a SRAM Rival 1 drivetrain for $1,999.

For complete spec and geometry numbers, check out the bikes at noble-bikes.com.