The bicycle is a pure, noble invention, which is probably why it attracts so many people who have prior experience in other industries. Take Adrian Bedford, for example. With a long background in engineering and product design, after two years at Dyson, Adrian found himself working in the aerospace defense industry designing in-flight refueling systems. In spite of being very good at what he does, Adrian said he would “sit there looking at what I was supposed to be working on, but thinking about bikes.” Pretty sure we’ve all been there at some point in our life.

The turning point for Adrian came when he was offered a summer job to guide riders in the Alpes. At that point, he had already begun tinkering with bike frames building his first in 2011, and he told himself that if his bike survived the summer, he’d start making bike frames. As you might have guessed, the frame passed with flying colors and Adrian made the switch to building bikes full time in 2014.

Originally, Adrian was in a tiny 2.5 x 7m workshop and even though he’s still not in a massive facility, he has quite a bit more room to work. Adrian moved to this space in Peebles, Scotland about six months ago and shares it with his wife who has a chiropractic office on one side, and some friends that do camper van conversions on the other side. Located right in the city center of Peebles, Swarf is very close to some of the best trails in the Tweed Valley which is to say some incredible riding.

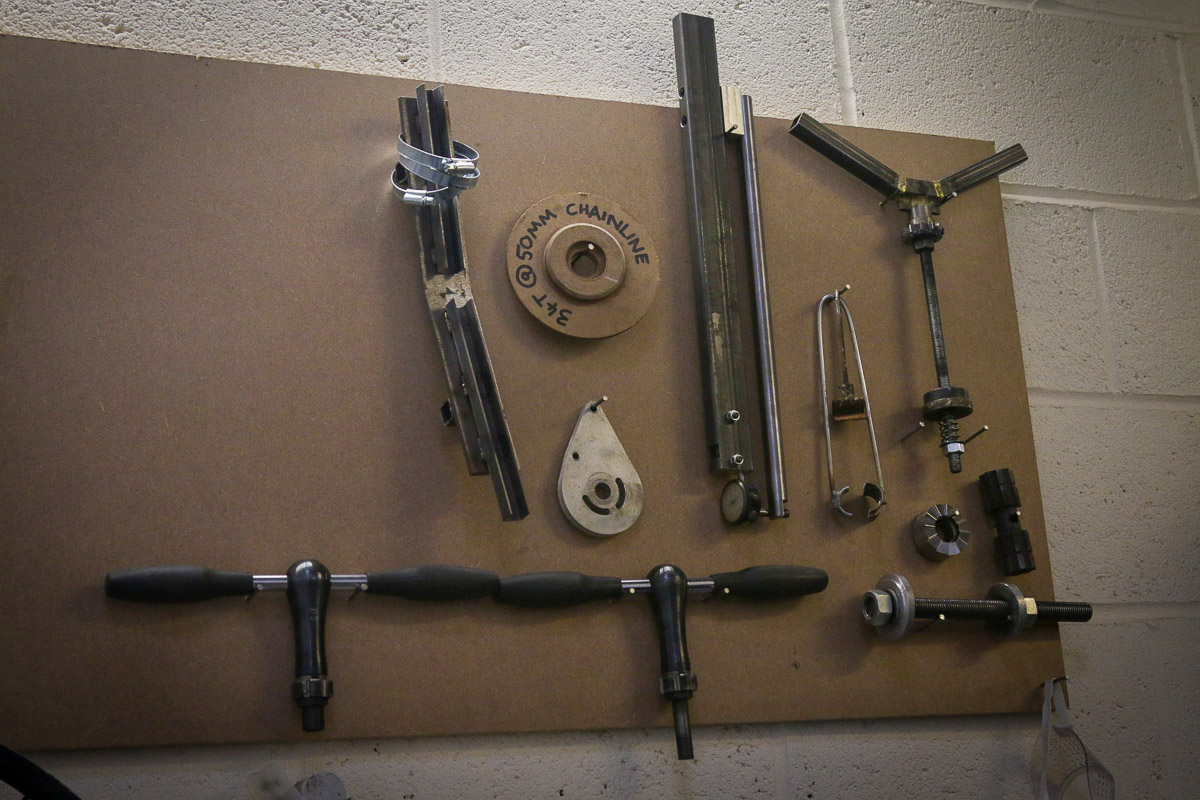

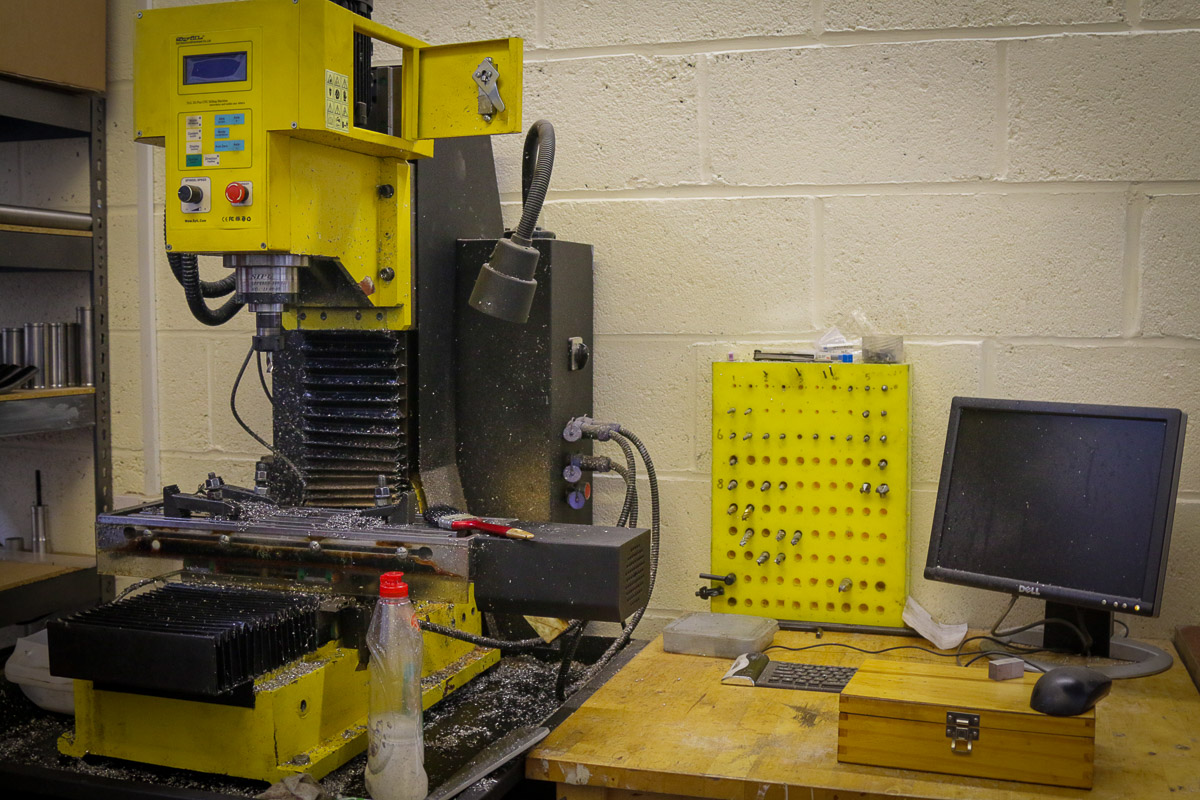

One of the more interesting features of Adrian’s first bike (green, above), was that it had a carbon fiber rear end with a steel front end. Adrian said the design was completely proven and was plenty durable for production but the swingarm just took him too many hours to manufacture. Since he was cutting his own molds in a machine shop, it took 6 months to get the molds together and then about 50 hours to build each swingarm. He continued with the carbon swingarm through the next version (red and blue, above), which still utilized a high pivot with a chain torque eliminator pulley.

However, when 29ers first started to roll out, Adrian decided that he would try out the big wheels by building some hard tail frames. While he liked the wheel size, he thought that a bit of suspension would be nice – which brings us to the current model.

Moving to a somewhat standard single pivot design, the Contour 29 is a short travel 29er with 115mm of progressive suspension. The seat stays are shaped to allow for some flex which is required to make the system work without a rear pivot.

Designed to work with a 130mm travel fork, this bike was yet again speced with a Cane Creek Helm – which seems to be a very popular option in the UK. Personally, one of my favorite design elements is how the seat stays flow into the top tube giving it the look of a hard tail, but with the ride of a full suspension bike. Claimed weight of the frame is 3.2kg without a shock, and it’s offered with either 142 x 12 or 148 x 12 rear ends with a 73mm threaded BB, 44mm head tube, and internal dropper compatible 30.9mm seat tube.

Available in three colors and four sizes, each bike is hand built by Adrian and prices start at £1950 for a frame and a RockShox Monarch RT3 rear shock. Adrian also still sells hard tail frames with the Spine 29 & 27.5, and can whip up full custom frames as well.