Like a lot of kids, Lili Heim works a summer job to pay for her new bike. Unlike a lot of kids, Lili’s dad is Hans Heim, the Co-Owner and CEO of Ibis. So when Lili gets a new bikes, she’s getting a new bike, like something completely new from Ibis. Originally inspired by his daughter’s high school XC racing, Hans wanted to build a light weight carbon bike that would be versatile enough for all around riding and racing, while not being astronomically expensive.

Enter the new Ibis DV9. This 29″ wheeled hardtail has a bit of a dual personality. On one hand it can be built as a full race bike with a 100mm Step-Cast Fox fork and 29 x 2.25″ tires, or as a trail worthy build with a 120mm fork and 29 x 2.6″ tires.

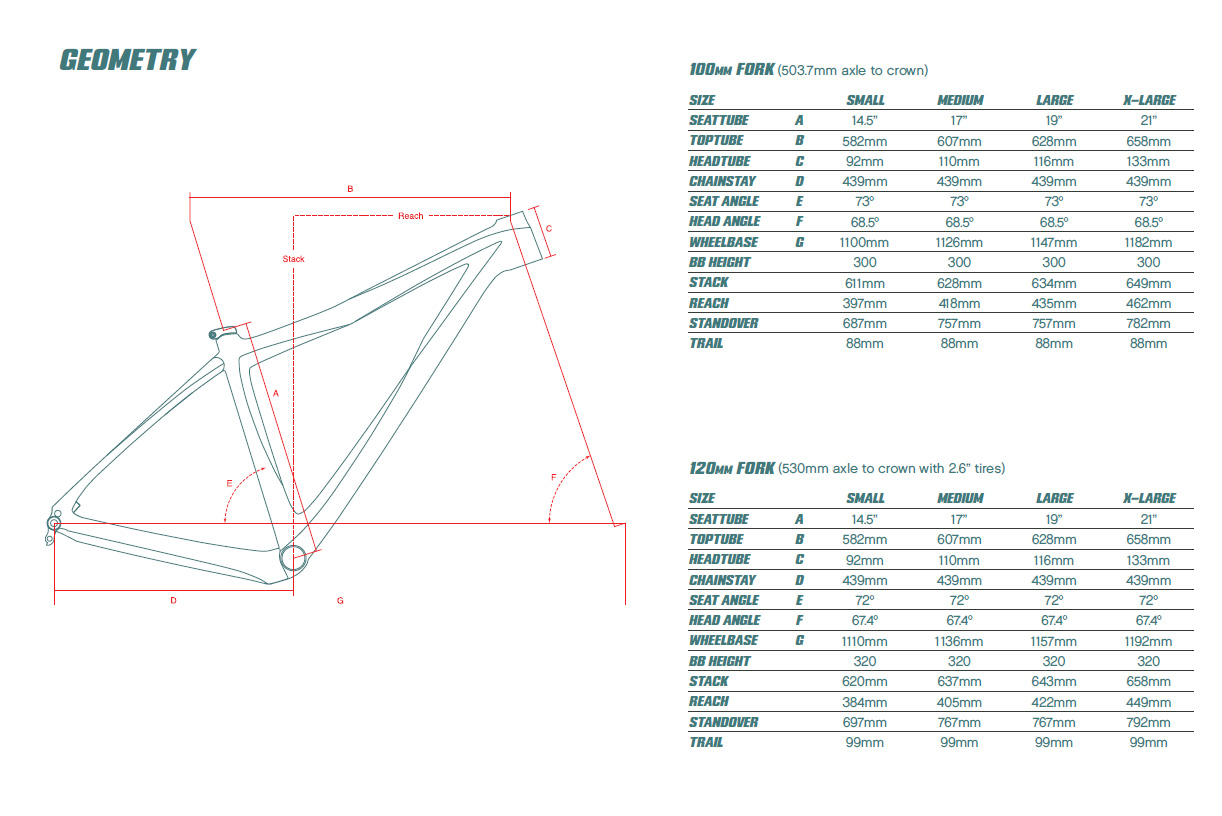

Built with slacker-than-XC geometry, the DV9 features a 68.5° head tube angle with a 100mm fork or 67.4° with a 120mm fork and 439mm chainstays.

At the back you’ll find Boost 148mm dropouts and post mount rear brakes with a 180mm max rotor size.

Tire clearance tops out at 29 x 2.6″ for trail use, or go full racer with the MTB equivalent of file treads.

The frame features a threaded bottom bracket with a 1x specific design, and has the ability to run an internal dropper post. Shift cabling is run internally as well, though the brake hose is kept external.

Pricing starts at $999 for the frame only, or $2199 for an NX 1×11 complete build. The sky’s the limit with XX1 Eagle builds going for $7499 or XTR for $7299. Available now.

- Wheel Size : 29″

- Tire Clearance: Upto 2.6″ tires

- Front Travel : 100mm/120mm

- Axle Width : 148mm rear / 110mm front

- Seatpost : 31.6mm

- Rear Brake : Post mount / 203mm max rotor

- Chainstay : 439mm

- Bottom Bracket: 73mm English Threaded

- Tapered Headtube: ZS44 upper/EC49 lower

- Max Chainring : 34T

- Not ISCG Compatible

- Colors: Bone White/Teal, Black/Orange

- Sizes: Small, Medium, Large, Extra Large

- Frame Weight : 1,204g

- Frame Warranty : 7 Years