Tracking power is probably the most key metric to targeted training for a specific event or discipline. Cyclocross also happens to be one of the most brutal on equipment. So we decided to put Rotor’s machined aluminum 2INpower power meter crankset to a long-term test, in the most difficult conditions we could drum up. How did it hold up?

Rotor 2INpower dual-sided power meter crankset

Rotor’s dual-sided 2INpower crankset power meters were debuted about two and a half years ago as an update to their previous single-sided INpower cranksets, adding true left-right power measurement. The crankset we have been testing for the last year is the previous iteration that included an integrated 110mm BCD machined spider, intended for road or cross use. Paired to that we have a set of Rotor’s oval Q Rings in a cyclocross specific 46/36 gearing combination.

Rotor’s dual-sided 2INpower crankset power meters were debuted about two and a half years ago as an update to their previous single-sided INpower cranksets, adding true left-right power measurement. The crankset we have been testing for the last year is the previous iteration that included an integrated 110mm BCD machined spider, intended for road or cross use. Paired to that we have a set of Rotor’s oval Q Rings in a cyclocross specific 46/36 gearing combination.

Rotor has since moved to a direct mount version that shares all of the same technology and sensors, but now you buy the same set of crank arms, then pick a discipline-specific set of direct mount chainrings. Oval Q Rings or round No-Q chainrings are still available in the new direct mount versions.

The premise for us testing the 2INpower cranks in the first place was the possibility to get left-right balance power metering that was up to the brutal task of autumn & winter cyclocross racing, then year-round off-season training on road & trail through harsh weather conditions.

Tracking power for cyclocross sometimes can seem like a losing battle to start with. Racing in short intense bursts around rough off-road courses, data often ends up bouncing all over the place. Plus, when you factor in extreme changes in temperature – for example taking your bike from inside room temperature directly out to below freezing to ride, or warming up in a heated tent only to race minutes later in the cold – and exposure to rain, mud, ice & snow, we wanted to see how the robust looking Rotor power meter would fare.

But in the end, if a rider is looking to improve in cross, even if the power data from racing itself can be a mess, tracking and training to power in the off-season is a must.

Rotor 2INpower power meter crankset – Tech Details & Actual Weight

As a true dual side measurement power meter, the Rotor 2INpower crankset features one set of sensors inside the driveside crankarm to measure right leg power, and a second set of sensors inside the spindle of the bottom bracket that measure left leg power. That means that the left crank arm is essentially ‘dumb’ (without electronics), which simplifies installation. All electronics and the rechargeable battery are housed in the one-piece right side crank arm + spindle.

As a true dual side measurement power meter, the Rotor 2INpower crankset features one set of sensors inside the driveside crankarm to measure right leg power, and a second set of sensors inside the spindle of the bottom bracket that measure left leg power. That means that the left crank arm is essentially ‘dumb’ (without electronics), which simplifies installation. All electronics and the rechargeable battery are housed in the one-piece right side crank arm + spindle.

Rotor claimed a weight for the 2INpower crankset of 645g, plus about another 155g for the set of Q Rings. Our test setup with the 2INpower crank and 46/36 rings weighed in at 791.5g.

Worth noting is that the new direct mount option that has since replaced these 110 spider cranks has trimmed off a bit of weight, with a new claim of 775g for a complete setup with road gearing.

Rotor 2INpower crankset & Q Rings oval chainrings – Setup

The 2INpower crank uses a 30mm axle, designed around a 86.5mm width bottom bracket, which meant it is generally compatible with the majority of new and old frames. The Stevens Super Prestige with a BB86 didn’t require any extra spacers with its press fit bottom bracket. Installation was simple and straightforward. And two cycles through the calibration process with my Garmin 520 head unit and it was good to go. (And according to Rotor, I did not need to recalibrate at all, besides one time after riding for 30 hours total.)

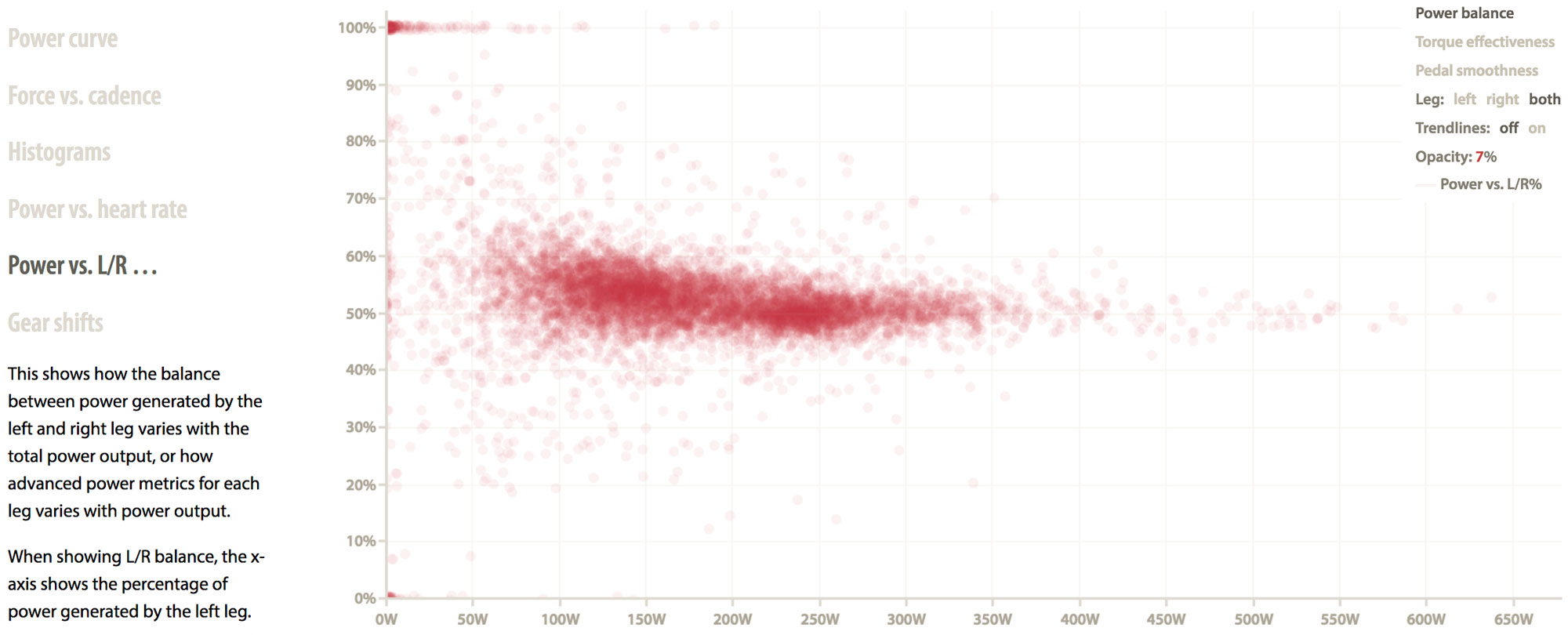

One of the benefits of true left-right pedal balance analysis, and the more detailed Torque Effectiveness and Pedal Smoothness data that the 2INpower collects is the ability to fine tune your pedal stroke. Or in the case of oval chainrings, to adjust and optimize the clocking of the rings’ eccentricity.

By connecting the 2INpower crank to Rotor’s Torque 360 app via Bluetooth or ANT+, the power meter transmits the full sample of 200 measurements per second to analyze your pedal stroke. My data essentially fell within the typical 87-93° range that put my Optimum Chainring Position at the middle #3.

Rotor 2INpower crankset & Q Rings – First Data & Impressions

The rationale behind dropping 1500€ on a 2INpower crankset (you can find them online for around 1100€ now that the new direct mount version is available) is probably for a year round tool for training with power. So I started with the crankset just riding as usual to collect the baseline data through last winter to see how it looked.

To be honest my training aspirations were a bit limited, but collecting the data was the first step anyway. The key to working with any power meter is really understanding what data you are logging and how to use it to your benefit. The most basic move to training with power is to move beyond training with heart rate, which has been generally demonstrated to be less effective.

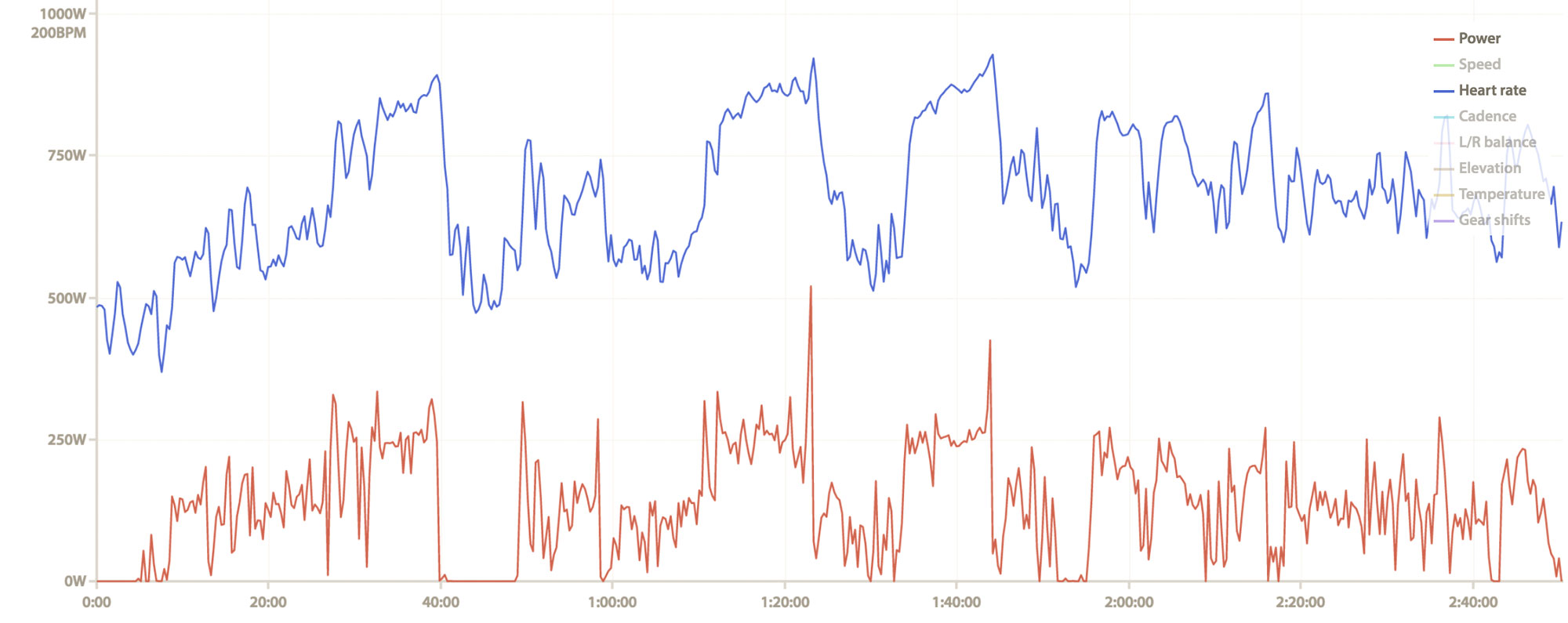

I’m quite into visualizing the data, so most of the time when I am trying to see what I’m collecting I pop the collected power data into something like CyclingAnalytics‘s visualization tools. Here I can see that power vs. heart rate data.

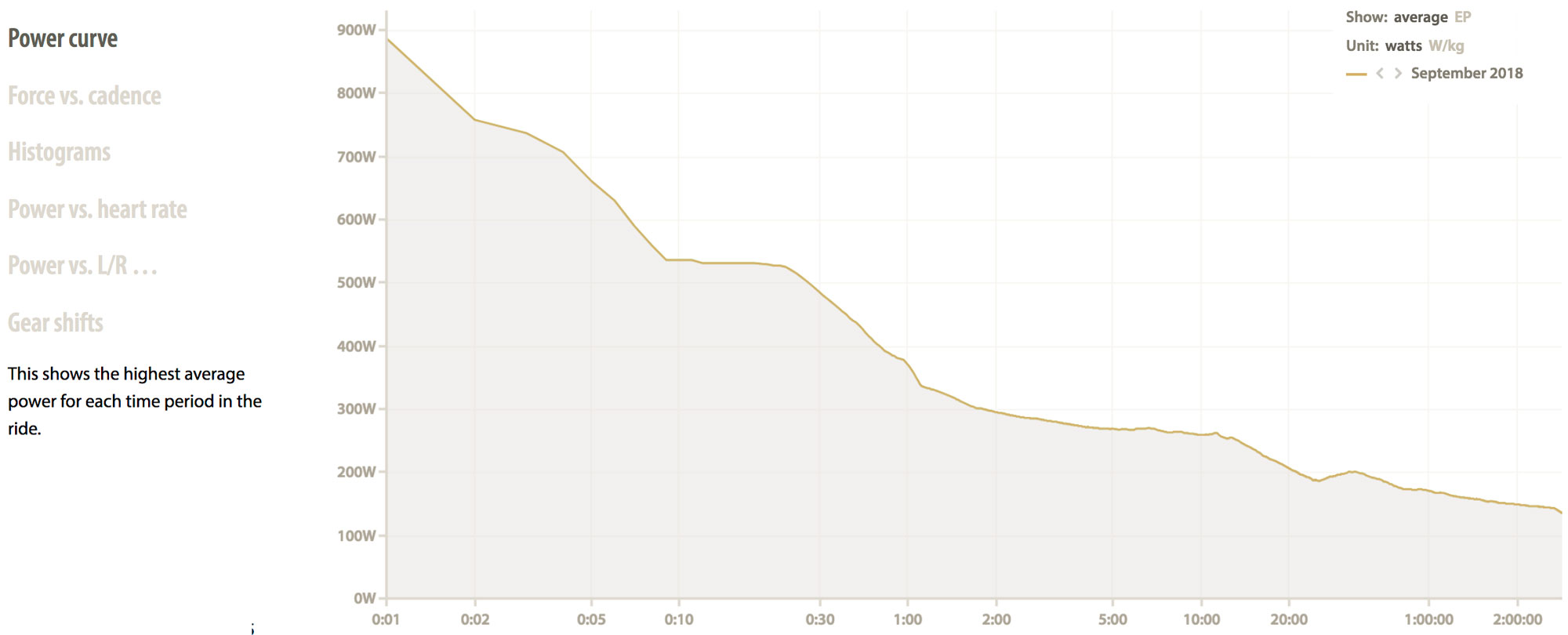

If you are looking to figure out what type of targeted training you are going to do, how & where you can improve, the old Power Curve is usually the starting point.

If you are looking to figure out what type of targeted training you are going to do, how & where you can improve, the old Power Curve is usually the starting point. Even though the Rotor 2INpower cranks sample data at 200Hz, live ANT+ communication to your regular head unit is going to be much slower at 4 times per second. That’s still plenty of data to see things like left/right balance on your display as you ride, but looking into the data post-ride can offer much more insight as well.

Even though the Rotor 2INpower cranks sample data at 200Hz, live ANT+ communication to your regular head unit is going to be much slower at 4 times per second. That’s still plenty of data to see things like left/right balance on your display as you ride, but looking into the data post-ride can offer much more insight as well.

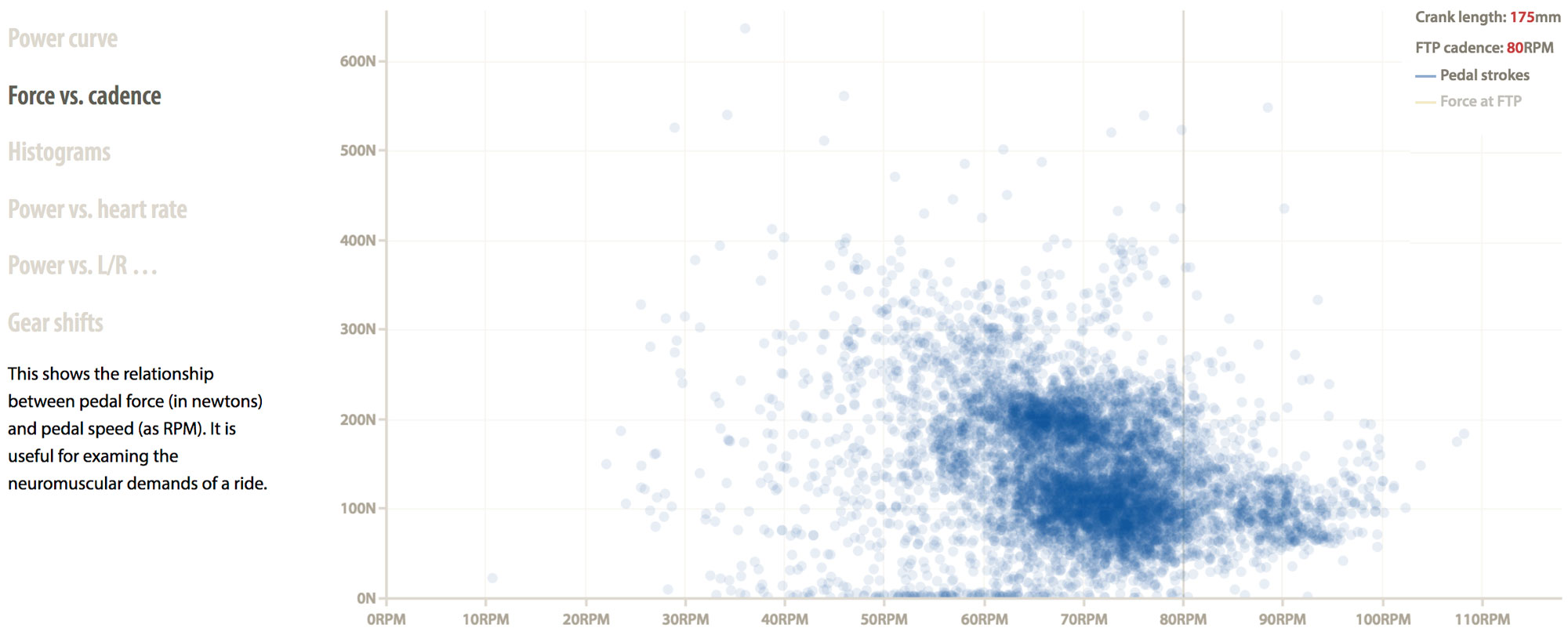

Hmm…. it looks like I favor my left leg at lower power output levels, but I end up pretty evenly balanced by the time I get up to around 220W. Also it seems that I put more force into the pedals at lower cadence (no surprise), but that the majority of the time I spend cranking out Watts (or rather Newtons here) occurs around two levels – higher output between 62-70rpm, or half that output between 65-80rpm.

Also it seems that I put more force into the pedals at lower cadence (no surprise), but that the majority of the time I spend cranking out Watts (or rather Newtons here) occurs around two levels – higher output between 62-70rpm, or half that output between 65-80rpm.

Now I just need to learn how to interpret all this data I am collecting.

That’s genuinely one of the biggest obstacles to benefiting from a power meter. Are you really going to get into all of that data? Is it worth it for the type of riding and racing you do? A power meter like this 2INpower crankset generates huge piles of data. Those four graphs are just a single 3 hour ride!

Rotor 2INpower crankset & Q Rings – Long-term Impressions

So let’s not sweat the numbers too much. It kinda hurts my brain. How did the 2INpower power meter actually hold up to regular riding, training & abuse? Well, suffice it to say, I’ve had really not problems with the power meter in just under a years time. I didn’t baby it either. Yes, it is sitting in a ice-covered lake above. Technically I was cleaning the mud off.

So let’s not sweat the numbers too much. It kinda hurts my brain. How did the 2INpower power meter actually hold up to regular riding, training & abuse? Well, suffice it to say, I’ve had really not problems with the power meter in just under a years time. I didn’t baby it either. Yes, it is sitting in a ice-covered lake above. Technically I was cleaning the mud off.

But there was plenty more mud to go around. While I ride an equal amount on mixed-surface roads and mountain bikes for around 6-8000km a year, anytime the weather is bad and I want to ride, it was this poor Steven’s cross bike that got tasked with riding. During that the Rotor powermeter was subjected to temperatures that ranged from around -10° to +30°C (14-86° F). Never did I see any evidence of the temperature affecting my power outputs, even heading out on those coldest rides where my Garmin (and the bike) went from 23°C / 73°F inside out to sub freezing temps.

But there was plenty more mud to go around. While I ride an equal amount on mixed-surface roads and mountain bikes for around 6-8000km a year, anytime the weather is bad and I want to ride, it was this poor Steven’s cross bike that got tasked with riding. During that the Rotor powermeter was subjected to temperatures that ranged from around -10° to +30°C (14-86° F). Never did I see any evidence of the temperature affecting my power outputs, even heading out on those coldest rides where my Garmin (and the bike) went from 23°C / 73°F inside out to sub freezing temps.

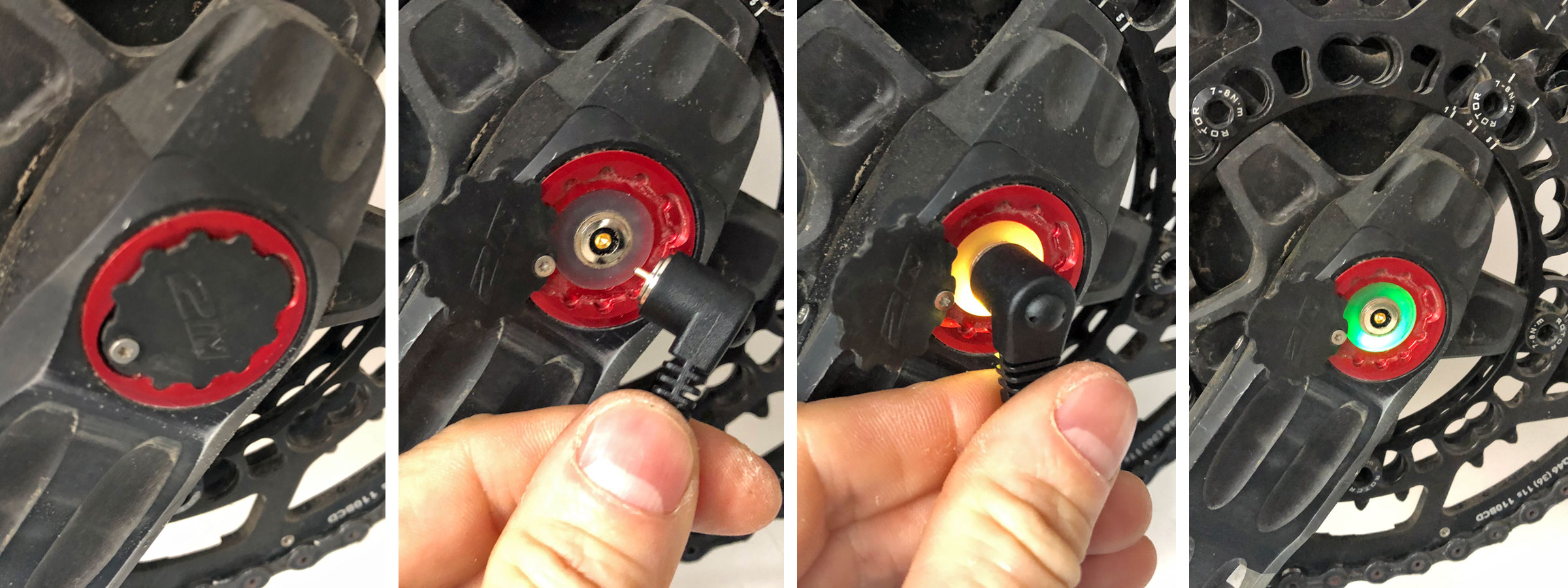

All of the electronics in the 2INpower power meter are housed either behind that small access panel on the top of the driveside crank arm, or inside the bottom bracket spindle behind the red charging port & its cover. The antennae & communication electronics are located in the extension of the crank arm to the left of the charing port.

All of it seems to be as well sealed as Rotor promises with IPX7 rated waterproofing. Even though it has spent almost a year on a cyclocross bike, I have kept the 2INpower cranks away from the pressure washer. I did use a pressure washer a couple of times to knock mud off the bike, but I always was careful to keep the stream away from the power meter. With that said, I did go to town on the cranks with a regular garden hose many times. And never once did I have any issue with water contamination.

All of it seems to be as well sealed as Rotor promises with IPX7 rated waterproofing. Even though it has spent almost a year on a cyclocross bike, I have kept the 2INpower cranks away from the pressure washer. I did use a pressure washer a couple of times to knock mud off the bike, but I always was careful to keep the stream away from the power meter. With that said, I did go to town on the cranks with a regular garden hose many times. And never once did I have any issue with water contamination.

Back to those Q Rings… they disappeared under me by the second or third ride and I never thought about them again. Every other bike I have ridden in the last year has had round rings, but I never noticed when I would jump back onto the Rotor Q Rings. I think the eccentricity of the Q Rings is just low enough that I didn’t really notice, while I apparently still got the smoothing benefits they claim. The only real noticeable difference I maybe encountered was riding some terrain with a 36T small ring where I would have normally used a 34T ring, without perceived additional effort. Not noticing them isn’t necessarily a ringing endorsement, but my takeaway is probably more on the line of ‘why not?’

Rotor originally quoted battery life for the 2INpower cranks at 300 operating hours, having since reduced that claim to 250 hours of real world use. I generally ride between 4-10 hours a week, which essentially would mean that I would only have to charge the cranks twice a year. I did go about four months before I first plugged the power meter in after its initial full charge, more just out of a feeling that I probably should charge it. In effect, the battery lasts long enough that most people can forget about it for months at a time. Then pull back the simple rubber cover and pop the magnetic plug on and charge it overnight by USB (yellow while charging, green when charged). The magnetic interface means even the charging port is fully sealed against water entry, so the rubber cover is just to keep mud & debris away.

Final thoughts training & racing cross with Rotor 2INpower crankset

So what are my final thought on training and racing cyclocross with Rotor’s 2INpower power meter crankset and oval Q Ring chainrings?

Well, the power meter itself has taken every bit of weather abuse I could throw at it, and handled it with no negative impacts. The power data has seemed consistent from start to finish, year-round, and offered more data than I know what to do with (or maybe just more data than I have time to properly analyze.)

Am I faster after a year riding the 2INpower cranks? Maybe a bit, but to be fair my commitment to structure training is to blame, certainly not a power meter that performed flawlessly. My cyclocross race power data seemed a bit more varied with more power spikes than what I saw on regular rides during the same period. But my Power Curves were pretty consistent. I would chalk a lot of that race data variation up to the huge variation of the different courses I raced – some flat, some steep, some slow & technical, others fast, and some where I was grossly outgunned by the competition.

I see more benefit analyzing the data during my training rides, both and off-road, which seemed to be more repeatable. But in any case, I can only say that the Rotor 2INpower crank did everything is claimed it would – logging my real left & right power data in all conditions, without any need for re-calibration after the first month riding it. At this point it is just up to me to use the data to work on bettering myself.

As for the Q Rings, a more detailed look into Rotor’s Torque 360 software comparing the oval rings with round ones might give me more concrete data. But for the time being I’m happy with the Q Rings performance and wear. And when they do wear out, I would likely replace them with the same thing.