As a reward for their first go at an aftermarket hub, ENVE came home from Eurobike with a Design and Innovation Award. But as they often say, while they were good, ENVE thought those hubs could be even better. Which brings us to the newest version, the Carbon Road Hub 2. Using the first iteration as a starting point, the new hubs offer better performance as a whole, from the bearings to the freehub to the flanges.

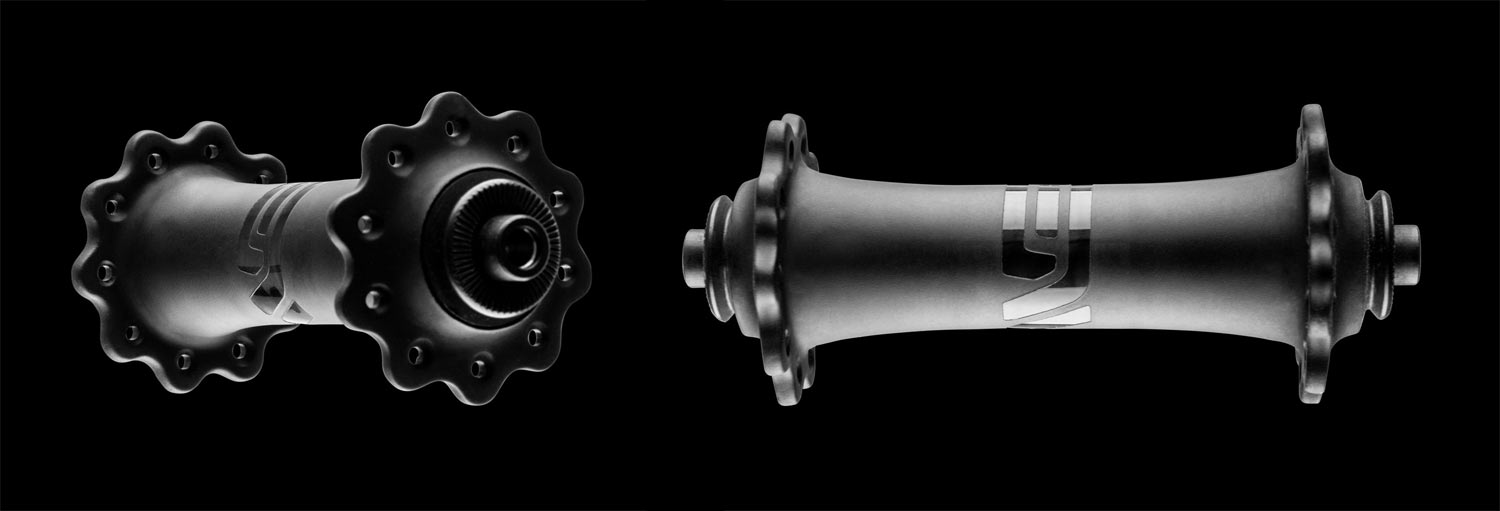

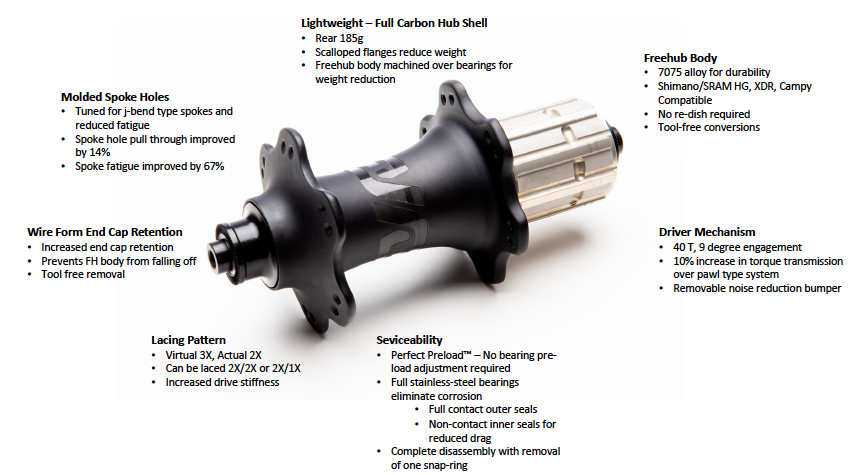

The US-made full carbon hub shell with molded spoke holes was a big part of what won ENVE the Design Award, so it’s no big surprise to see those features carry through. But the shell has been further optimized for even better performance. By reworking the flange geometry and design, the second generation hubs offer a stiffer rear wheel, better spoke pull through values, and three times the hub flange and spoke fatigue life than the originals.

Why change a good thing?

The original design used DT Swiss 180 internals, so it modeled its flange width and size after those hubs. They did this so that performance would be predictable, since the forces acting on the internals would be the same as what’s been proven for years on the 180s.

The new hubs, however, take advantage of parent company Mavic’s manufacturing capabilities, which opened the door to a completely proprietary, purpose built solution. Inside is an exclusive-to-ENVE bearing, axle and freehub body arrangement using Mavic’s top-of-the-line ID 360 ratchet ring 40-tooth, 9º engagement mech. ENVE’s Jake Pantone tells us the ratchet mechanism is the only parts these hubs share with Mavic’s hubs, the rest is their design, made in Europe by Mavic’s facility.

With new internals, they were free to maximize the outer performance however they wanted, then build the internals to match. So, compared to the original rear hub’s 45mm flange diameter, these push it to 55mm, and they get slightly wider spacing. The result is better spoke triangulation, which results in a wheel that’s both laterally and torsionally stiffer.

Pantone says the reduced torsional flex not only and improved torque and power transfer, but also reduces brake rub. He said that, because their brake tracks are finished for higher friction, that any rubbing can be audibly annoying, so fixing this wasn’t just a performance thing, but a user experience thing.

The process let them rethink the assembly of the hubs, too. The bearings are kept in adjustment over the long term thanks to their Perfect Preload system. By using a tuned wave washer between the bearings and a snap ring on the axle, the system maintains ideal preload on the bearings but never requires adjustment from the user.

And those bearings have been improved, too, but maybe not how you would expect. Rather than the ceramic bearings of the original, ENVE has switched to high quality stainless steel sealed cartridge bearings. They say the reasoning is that while the ceramic bearings offer great performance initially, they don’t offer the long term durability of their stainless counterparts.

Overall, the hubs are somehow even lighter at 70g for the front and 185g for the rear, and are available only for rim brake road bikes. Hubs are available separately with the 20h front selling for $400, and the 24h rear priced at $600 with your choice of freehub type (Shimano, SRAM XD or Campagnolo)…which is on par with what ceramic bearing-equipped DT 180s retail for. They’ll also be available as a complete wheel build with ENVE rims for $3,000…which is a $500 drop from the original price with their first gen carbon hubs.

What about disc brakes?

They’re working on it. Pantone told us it’s more challenging than you’d think to design something that offers a compelling benefit over what’s currently out there. With the standard rim brake hubs, they knew what they could to to improve them. These carbon hub shells are made in-house at their Ogden, Utah, headquarters and factory, then assembled with the internals from Europe. So there’s a lot of R&D costs followed by tooling costs, which means, for them, there needs to be a real reason to make it. But it’s on their roadmap, which would mean thru axle designs, too.

Learn more at ENVE.com