German 3D printer specialists BigRep have used their newest flexible Pro Flex polymer filaments to create The Airless Tire, a 3D printed honeycomb tire that snaps onto a regular bicycle rim offering a comfortable ride, limitless tread possibilities, and no more flats. And it isn’t just limited to bicycle tires, the same tire has been put to task in a prototype e-motorcycle, and more heavy applications…

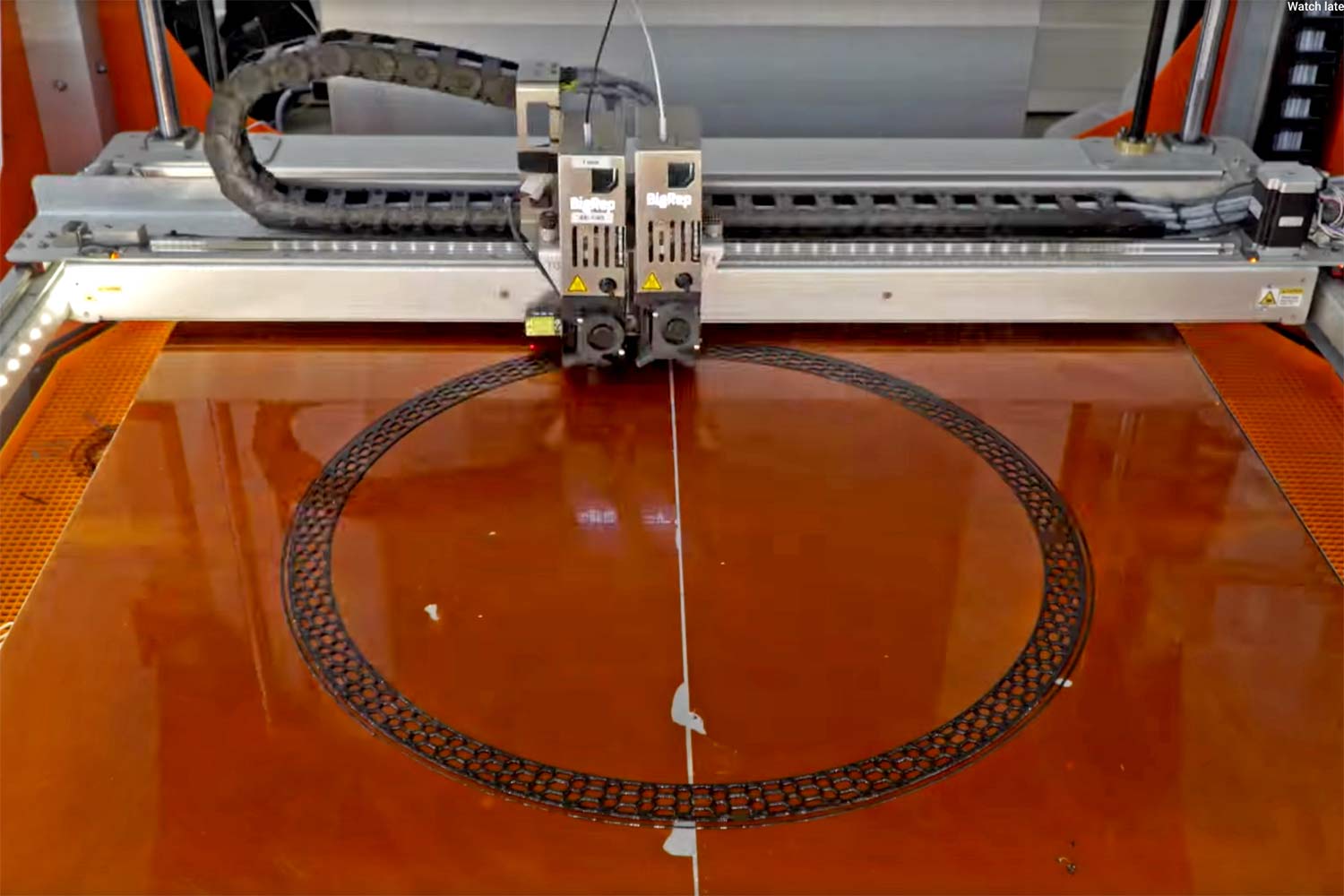

BigRep 3D printing with Pro Flex TPU filament

While the idea of a single city bike that can no longer get a flat tire is a cool idea, this material itself is probably the most interesting news out of the story. In the last few years 3D printing has evolved out of rapid prototyping, opening up real manufacturing potential.

Now some of the biggest innovation is in new materials to work with, and companies like BigRep that sell the 3D printers themselves and the filaments are showing ways to actually use the new materials for real product manufacturing.

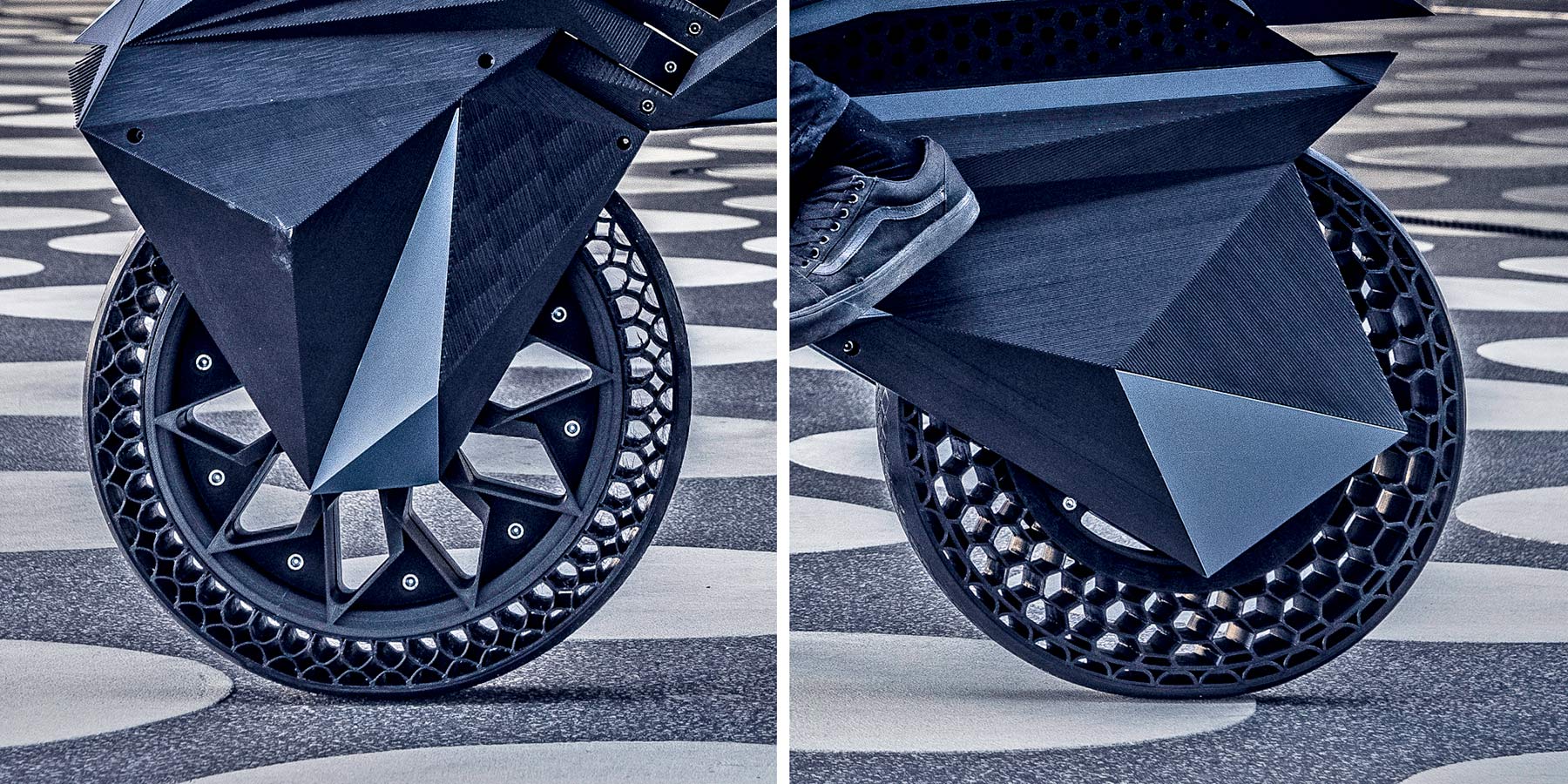

The Airless Tire, NowLab’s prototype bike tire

The Airless Tire was created by Marco Mattia Cristofori, a designer in the Berlin-based 3D printer company’s NowLab, developing new applications for additive manufacturing.

The tire material itself is Pro Flex, a durable thermoplastic polyurethane (TPU) based filament that retains the flexibility of TPU.

Printing elastomers in a 3D printer has been a difficult obstacle for additive manufacturing, so it’s quite unique to be able create objects now that retain durability, flexibility & damping. That of course is why you can build up an airless tire, layer-by-layer, unlike the more conventional solutions already in the market that require complicated molding & post-processing techniques.

The end result is an airless tire that flexes like a rubber tire thanks to a layered honeycomb design, which can get whatever tread design you need simply printed onto its casing. And it requires no additional processing after being printed.

Just pick it up off the 3D printer bed after the 16 hours it took to create, and stretch it into place over the standard bicycle rim.

Of course, these are all only prototypes for now (albeit, functional ones.) BigRep sells the 3D printers & filament to manufacturers to create products as they see fit.

A more developed Airless Tire product would have to address in more detail the interface with the rim (although, having used tubular clinchers from Tufo in the past, I can imagine how that could possibly be solved). But further development also opens up the possibility for a more natural curved tire profile, and additional tread pattern options. And with additive 3D printing, more complex internal design could offer varying levels of comfort & support as you lean the tire over towards its sidewall…

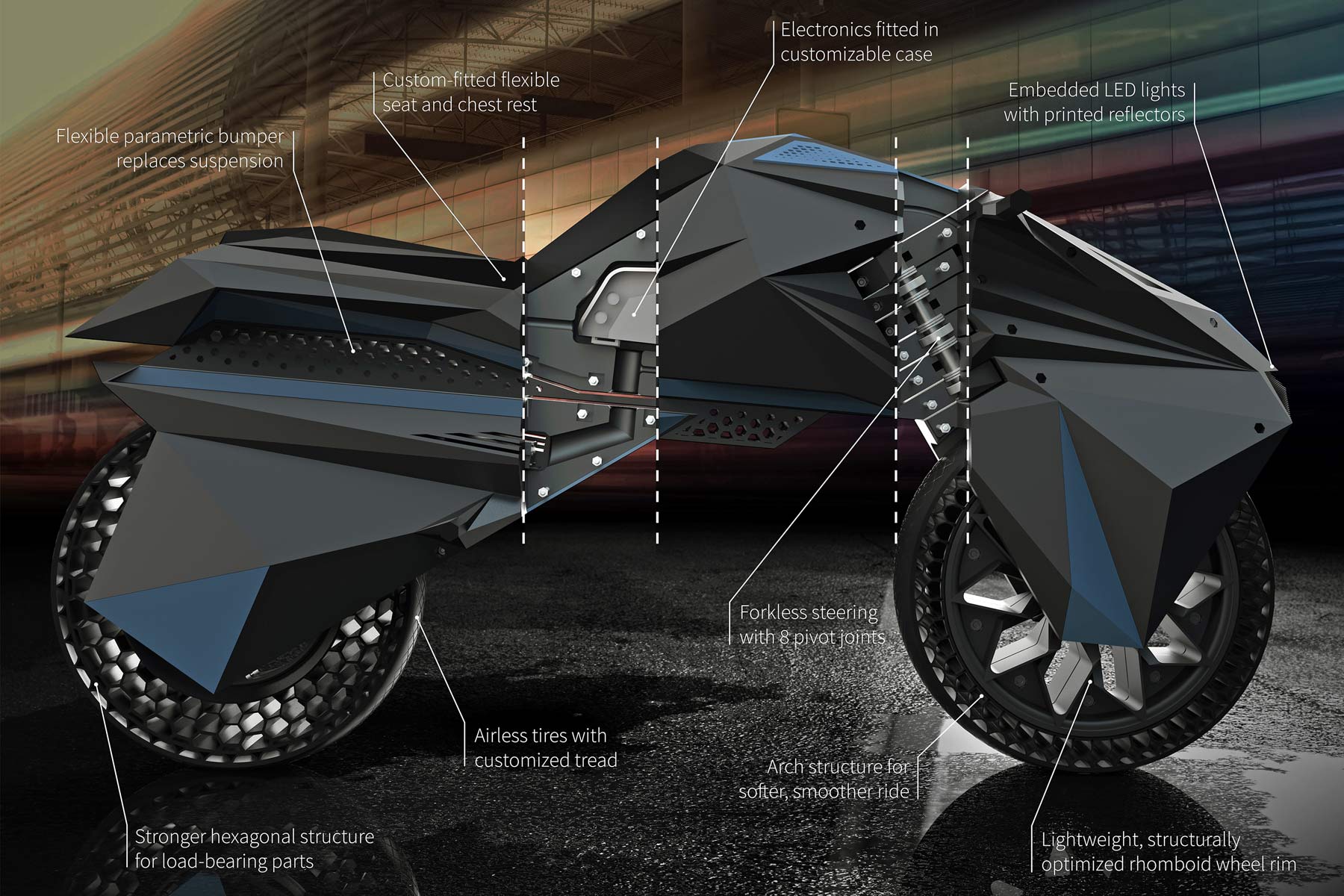

Nera, NowLab’s prototype e-mobility electric motorcycle

It certainly doesn’t stop at bike tires. Cristofori also recently completed a functional prototype of a fully 3D printed Nera e-motorcycle for getting around the city.

The resulting Nera is an adjustable fit e-moto printed over a three-week period on BigRep’s printers mixing four different material.

Of course it gets similar airless tire tech, but here uses an arch-based design in the front tire for more comfort, and the hexagonal structure in the rear for additional strength & support.