One of the more recognizable names in motorsport, Pirelli also has quite the history when it comes to bicycle tires. In fact, the company’s first tires were pneumatic bicycle tires – at a time in 1895 when such a thing was revolutionary. As technology evolved, Pirelli followed up with motorcycle and then car tires, and growing to become the industry giant they are today with 18 production plants, 30,000 employees in 160 countries, a global R&D center in Milan plus 10 others around the world, and roughly 5.3bn euro in revenue in 2017.

When it comes to bicycle tires though, after the 1980’s, Pirelli focused their attention on other wheeled vehicles. So when the company launched the PZero Velo in 2017, they weren’t entering the bike market, they were reentering it. But when it comes to mountain bike tires, for Pirelli, this is all completely new ground. However, it’s also not that much of a departure for a company that specializes in creating new rubber compounds and has a motocross background with more than 70 world MX titles to their credit. That motocross connection is actually where the Scorpion line gets its name. Now adopted for the world of mountain bikes, the Scorpion MTB range has just been unveiled with four models developed to simplify the tire selection process.

In terms of selecting a tire as a consumer, Pirelli noted that it can be a daunting task due to the huge selection in terms of tires and sizes to choose from. Between the disciplines like XC, Trail, AM, Enduro, FR, & DH, and the number of casing, tread pattern, and volume choices within those categories, it’s easy to see how picking a set of tires might lead to analysis paralysis. Pirelli then specifically does not want to talk about disciplines, instead focusing on “Racing XC, Riding for Fun, and DH Racing” as categories and creating a naming structure that is easy to understand, choose, and use.

The result is the relatively simple H, M, S, & R tire designations, which are color coordinated. The ‘H’ is for hard pack terrain, ‘M’ for mixed terrain, ‘S’ for soft terrain, and ‘R’ as a designated rear tire. All of the tires are tubeless ready, and they all feature a specific version of Pirelli’s SmartGRIP Compound.

This is where the tire construction takes an interesting twist.

We’ve grown accustomed to tire manufacturers extolling on the virtues of multi-compound construction. Usually with a harder compound at the base of the tread pattern for support, followed by slightly softer compounds in the middle of the tread, and the softest compounds at the edge of the tread for increased grip. Pirelli claims that due to their expertise in compound development, that is no longer needed. Instead, the Scorpion tires use a single compound through the tread which has been customized for each model and size. Supposedly, this prevents different rubber compounds from reacting differently to the climate or temperature, and also guarantees consistent grip even as the tire wears – since you’re no longer able to wear through the softer rubber on top, exposing the harder rubber underneath.

Pirelli goes further to say that SmartGRIP was designed specifically to address the needs of a compound that is resistant to tears while maintaining wet grip. Each compound has been customized in both static properties (hardness and breaking strength) and dynamic properties ( damping and dynamic stiffness), for each tire size and model which Pirelli calls an industry first.

That goes hand in hand with a size specific development process that resulted in different tread design for each tire size and model. Depending on the tire’s size, Pirelli tuned the knob spacing, size, tread height, knob shape, and siping to maximize the tread performance based on the intended use and tire footprint. The same could be said for the tire construction in terms of the carcass itself. Rather than offering every tire in every casing, Pirelli says that every tire gets a specific casing with smaller tires getting a lighter, more supple 120 TPI casing and larger tires (for the most part) gain a more durable 60 TPI casing. Certain tires like the 2.4″ LITE casing tires still get the 120 TPI casing (with an additional 120 TPI reinforcement), but all of the 29 x 2.2″ tires go with the 120 TPI casing and aren’t offered in 60 TPI. This will generally continue as Pirelli fills out the product line which will eventually grow to include 29 x 2.2-2.6″ and 27.5 x 2.4-2.6″ tires.

The biggest takeaway here is that Pirelli claims each tire size had its own development process. They didn’t simply design the ‘H’ tire, and then grow it or shrink it to fill out the line. Each tire size and model had its own “tailored development” process that led to the final product you see here. And once they were ready for testing, Pirelli put their army of product testers to work with a litany of tests across the globe in every condition and as many different terrains as they could find.

Scorpion MTB H

Getting into the tire specifics, the Scorpion MTB H is a low profile tread for hardpack terrain in both wet and dry conditions. The larger the tire, the more aggressive the cornering lugs are, but overall it has a tightly spaced center section for low rolling resistance and a number of small knobs for grip on hard and rocky terrain.

Scorpion MTB M

The Scorpion MTB M on the other hand is for Mixed conditions, again in both dry or wet. Built with slightly larger knobs with more space between then, the tire also features rubber bridges between the knobs to cross-link and reduce the movement of individual knobs and prevent tearing.

Scorpion MTB S

Scorpion MTB S is all about soft conditions and features the largest, most widely spaced tread blocks for wet or dry riding. Again, rubber bridges link the center knobs, to the transition knobs, to the cornering knobs. If you really want to geek out about tire design, Pirelli pointed out that the S model has the lowest Land/Sea Ratio at just 15%. That has to do with creating the right tread pattern for the terrain. So where a completely slick tire has a land/sea ratio of 100%, tires meant for wet sloppy conditions have much lower ratios. Comparatively, the H sits at 27%, the M at 21%, and the R at 24%. The S also has the highest puncture resistance with a max punctual pressure of 0.17 kg/mm².

Scorpion MTB R

While you can run any of the aforementioned tires as a rear tire, the Scorpion MTB R is specifically developed as a rear tire for increased traction and durability out back. Pirelli recommends this for everything but soft conditions, so it would make a great rear tire with an H or M up front.

Weights and sizes

For all of the 29er tires included in the initial launch, Pirelli recommends 25mm inner width rims for the 2.2 sizing, and 30mm inner widths for 2.4″ and above. In terms of the actual weights, note that all of the tires weighed above are preproduction samples. For the most part, all of them weighed more than their claimed weights with the exception of the Scorpion MTB S, which checked in a few grams less. It will be interesting to see how the production weights stack up considering that 800g for a 29 x 2.4″ tire is pretty awesome, though the 903g weight of the Scorpion MTB H measured seems a bit more realistic.

Availability and Pricing

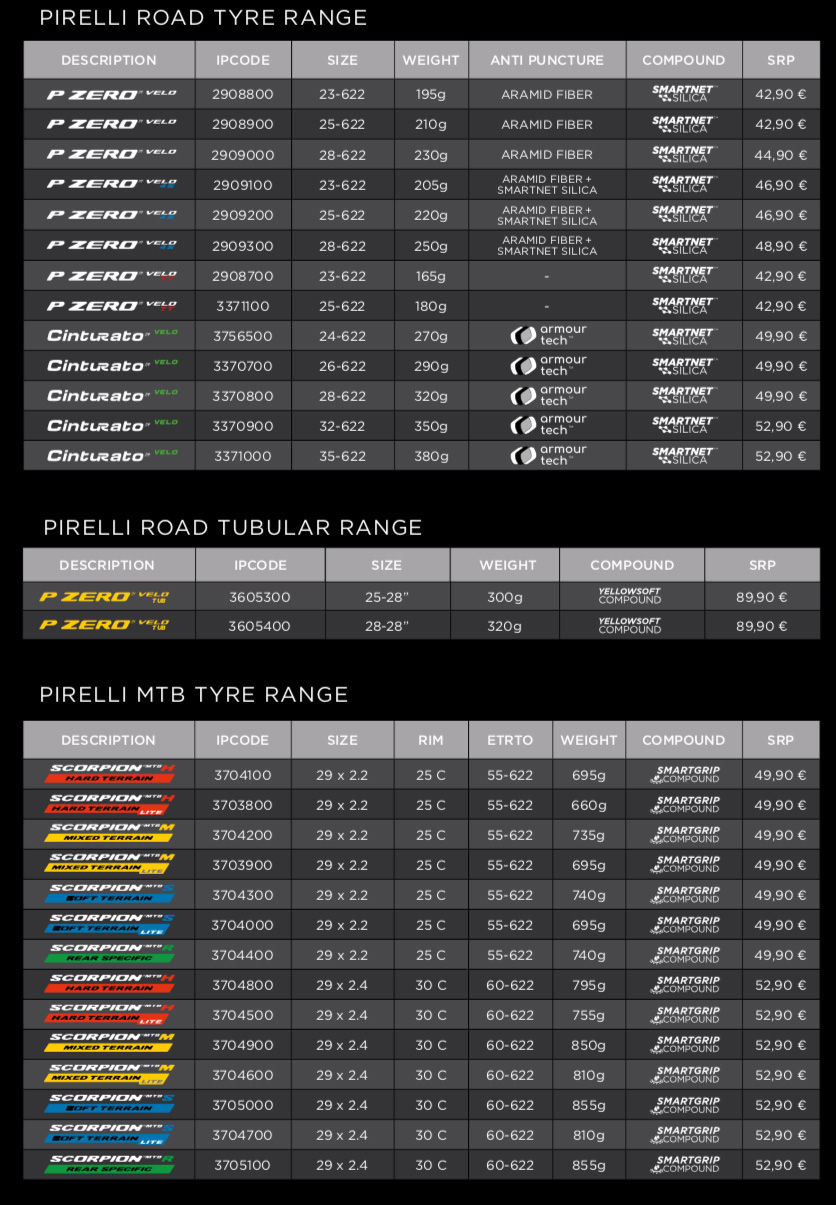

In terms of pricing, Pirelli’s Scorpion tires are priced by the size, not by the model. They state that this is because they are priced by the amount of rubber that is used, not the construction. With that said, 29 x 2.2s will start at €49,90, and 2.4’s jump to €52,90. The first 29″ tires will start to roll out in March, followed by 27.5″ and 2.6″ widths in July, and the remainder of the tires filling in by September. If you’re looking for more enduro focused tires, we’re told 2020 might be the year.

Stay tuned for our thoughts on the first ride, next!