When you’re a small frame builder making your own frames, it can be easier to quickly adopt to new trends. As such, Lynskey already has a few different gravel bikes in their line up, but they’ve just added one more. Picking up where the PRO GR left off, the new PRO GR Race is just that – a slightly racier version of their top end gravel rig designed for fast, comfortable gravel riding.

Utilizing a shaped 6AL/4V titanium top tube and a 3AL/2V aero downtube, Lynskey claims that the titanium frame closes in on the ideal blend of comfort and frame stiffness.

All of the cable routing is now internal using their tube within a tube routing system which claims to eliminate rattles and offers push-through cable routing. Otherwise, the specs are mostly the same with flat mount disc brakes, a tapered head tube, BSA bottom bracket, 27.2mm seat post, and 12 x 142mm thru axle. One big change though – the frame is able to clear only 700c x 35mm tires, which is quite a bit smaller than the 700c x 45mm clearance on the PRO GR.

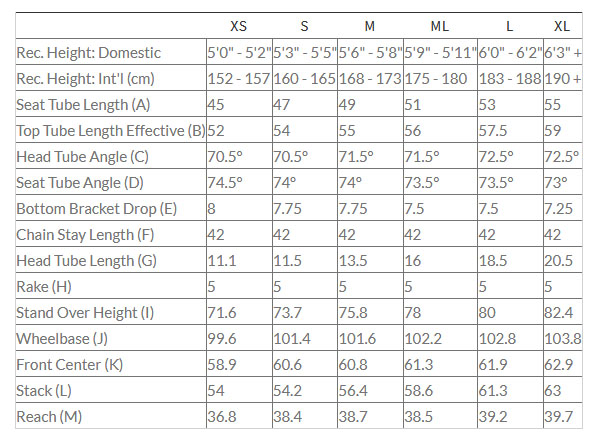

In addition to the change in cable routing and tire clearance, the PRO GR RACE also gains new geometry that is a bit more, well, race-y. Both the head tube and seat tube angles are 0.5° steeper than the PRO GR, and the chainstays shorten by 15mm. There is also a corresponding shortening of the wheelbase and a few other minor changes.

Offered as a complete bike with a Lynskey PRO GR gravel fork with 12 x 100mm thru axle, the base build with a SRAM Force 1x group starts at $4,050. From there you can custom tune your build with different frame finishes, frame graphics, head badges, wheels, drivetrain, and cockpit options. Available now.