CeramicSpeed continues to push the performance of their award-winning, chain-less Driven drivetrain concept forward. The idea from the start was to create a more efficient drivetrain than a conventional chain & cassette, but aerodynamic efficiency was always lurking in the back of their engineer’s mind. Now with a new cowled design and a partnership with Specialized, CeramicSpeed have taken a Driven-equipped S-Works Venge into the wind tunnel to set a benchmark as the “world’s most aerodynamic drivetrain”…

CeramicSpeed Driven world’s most aero drivetrain

It’s not a huge surprise that by taking a spinning chain, cassette & derailleur out of the wind, CeramicSpeed’s drivetrain could be more aero. But they wanted to quantify just how much drag they could save, so CeramicSpeed partnered with Specialized to use their Win Tunnel for some actual testing.

UPDATE! See how it shifts and their new MTB version IN THIS POST!

It’s important to note that the Driven drivetrain concept is still just that – a concept. But it’s a concept that seems to have some real potential, both in terms of drivetrain efficiency and aerodynamics. Thanks to 21 CeramicSpeed bearings attached to the end of a pinion-drive shaft, the drivetrain claims to have an “increased optimal efficiency of 99%” compared to a traditional chain driven drivetrain. But the elimination of some moving parts also seems to have a slight effect on aerodynamics with a 3% gain.

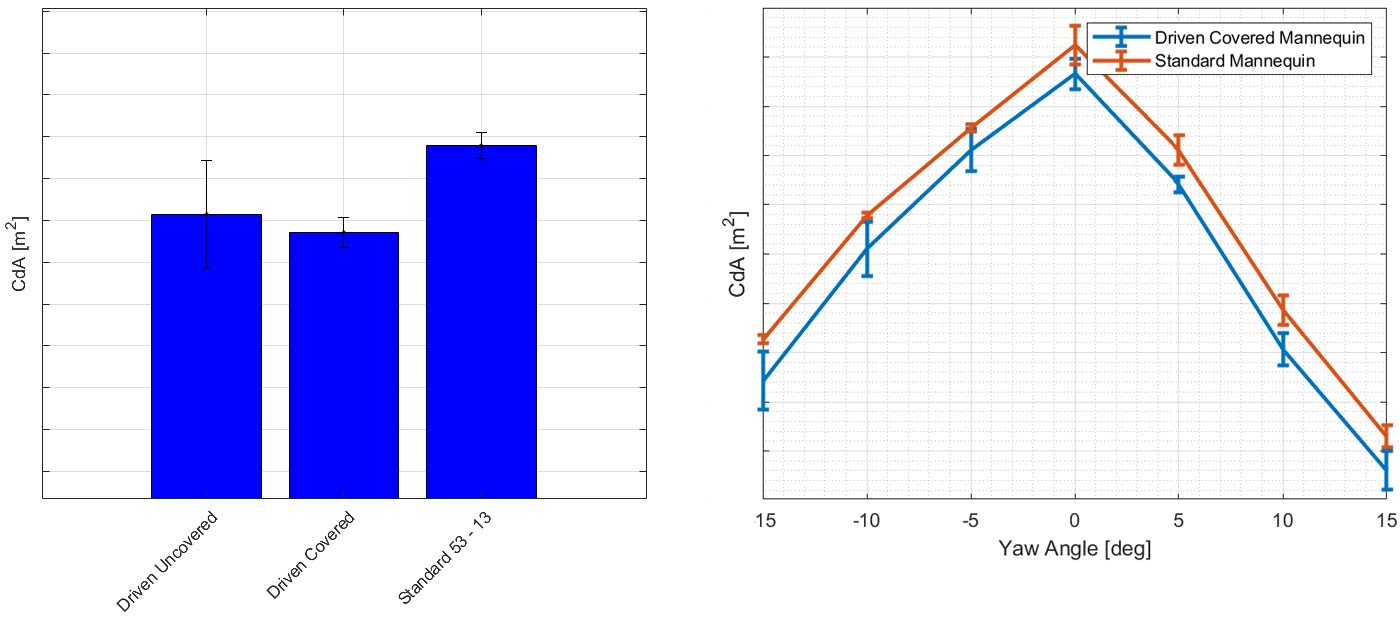

The testing was performed with a current Specialized Venge that was equipped with both a standard drivetrain in 53 x 13 gearing, and the Driven chainless drivetrain. The Driven drivetrain tested faster both with and without the new cover, and the covered Driven drivetrain was more aerodynamic across all yaw angles.

If you’re in search of the fastest road bike period, it seems like there is some promise in the Driven concept. Of course, the drivetrain will also need to be light weight and durable enough to withstand real world abuse. CeramicSpeed claims that they’ve been doing rider load testing at a velodrome where they have reached speeds of 45km/h, and they’re working on a shifting mechanism to go along with it. Is this the future of bicycle drivetrains? Only time will tell…