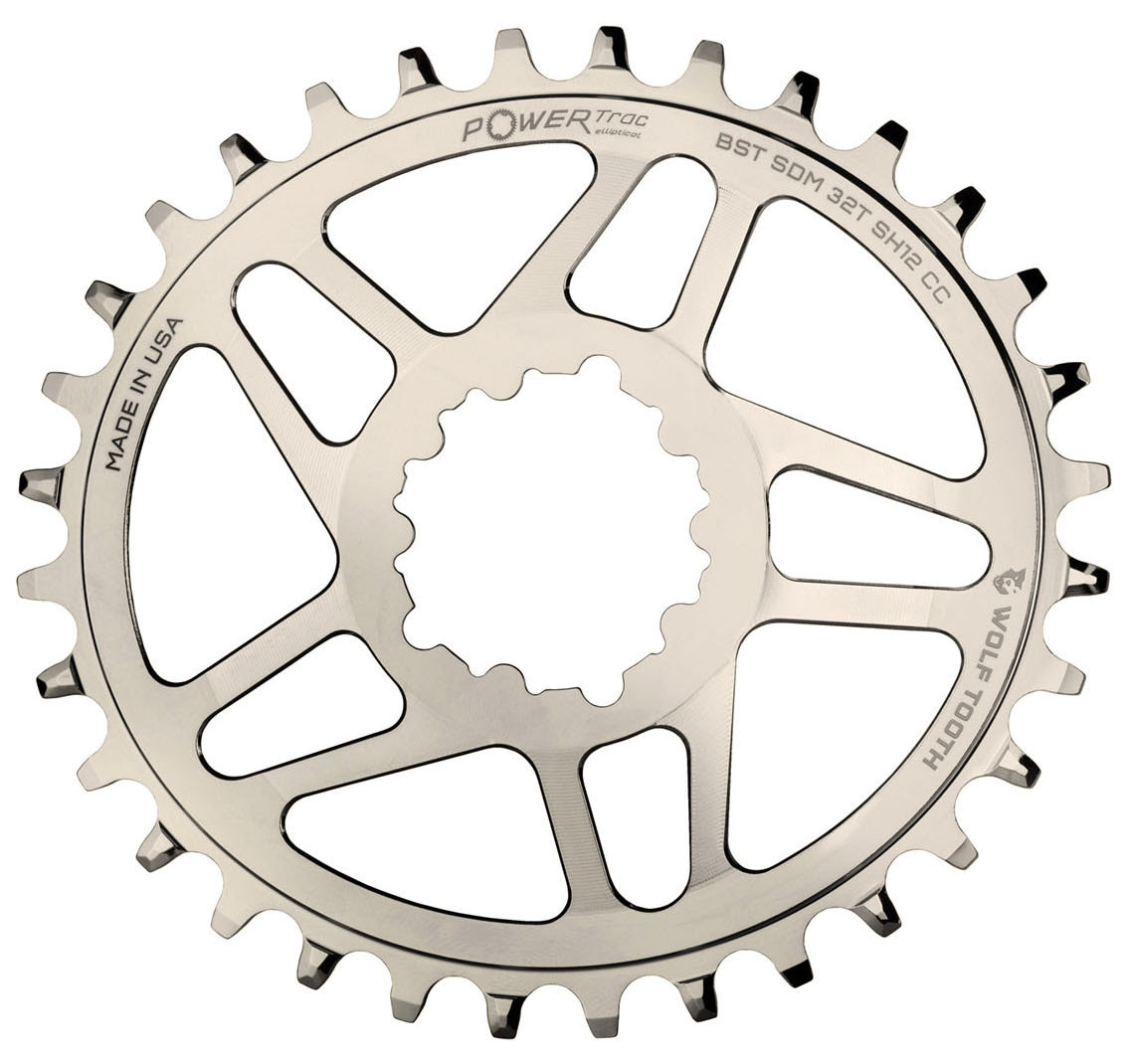

What’s the ultimate set of cranks without the ultimate chainring? To answer that question, Wolf Tooth Components has teamed up with Cane Creek to create the perfect pairing for their eeWings titanium cranks. Starting with their updated SH12 Drop-Stop tooth profile, Wolf Tooth Components has added a nickel plating that is designed to look stunning when paired with a set of eeWings.

Offered in both round and their PowerTrac Elliptical profiles, the chainrings use the 3-bolt SRAM Direct Mount standard to be compatible with the eeWings. In order to be compatible with the new Shimano XTR, XT, and SLX 12 speed Hyperglide+ drivetrains, WTC developed a new tooth pattern optimized for their use.

The chainrings are still made in the USA out of 7075-T6 aluminum, but they undergo a nickel plating process to give them their unique look. Both models come only in Boost offsets with the PowerTrac ring available in 32t, and the round in 32 & 34t. Each model sells for $79.95 and claimed weights range from 70-75g. Available now.