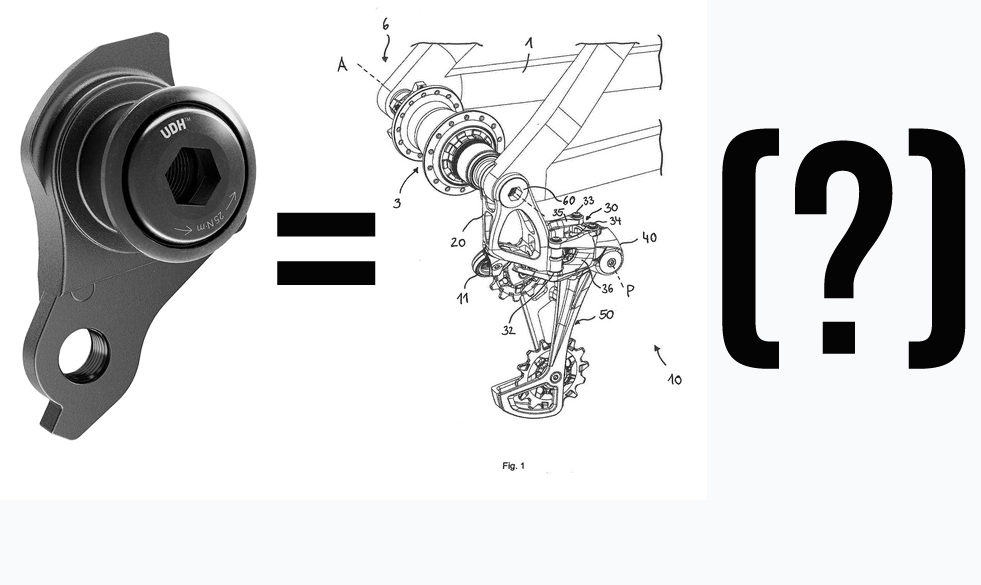

Sometimes it takes an outside eye to put two and two together. Recently, SRAM introduced a universal derailleur hanger concept at Eurobike that has a lot of potential benefits. A single hanger across brands would mean replacements would be far easier to find, and the hanger design itself has a lot of cool features that improve on the standard design. But as a reader just pointed out, it may also have implications for the design of the derailleur itself.

Back in 2018, we covered a patent from SRAM that involves a coaxial installation for a rear derailleur. To put it simply, the design mounts directly around the axle without a derailleur hanger. The patent discusses the differences in tolerances between existing hanger designs and also notes the increased forces on the derailleur hanger from longer derailleurs needed for today’s huge cassettes. The direct mount derailleur would theoretically improve these tolerances and offer a stiffer, more precise shifting platform which could be necessary for future drivetrains (more speeds?).

But a big stumbling block to the design would be the difference in current frame designs. In order for direct mount derailleurs like those in the patent drawings to work, you would need some kind of universal standard… like that provided by designing frames around a universal derailleur hanger (or as a friend pointed out, what was already offered through a design like Shimano Saint where the derailleur bolted to the end of the axle).

While this is all purely speculation, it looks like SRAM’s universal derailleur hanger concept would result in a frame design that you could simply remove the universal hanger, and instead mount a direct mount derailleur. That way, the frame would be compatible with standard derailleurs that currently exist (with all of the improvements of the new hanger design), and they would also be compatible with this new derailleur design. Everyone wins, right?

We’ll see…