You can say that road tubeless is one of the most hotly debated concepts in cycling these days. And the hookless bead even more controversial. ENVE makes rims both with and without bead hooks, so they wanted to explain…

Why hookless beads are the future!

The latest in the ENVE Journal’s ‘Behind The Product‘ series tries to set the record straight on hookless beads, especially for road and gravel. Most performance mountain bikers settled on tubeless many years ago, and the tubeless-ready mountain bike tire & rim markets have stabilized in the year’s since with near-universal fits, and more-and-more hookless adoption.

With less of a legacy to overcome than pure road, All-road and Gravel are quickly adopting tubeless. And many of those wheels are already hookless. But like Road Tubeless, still in its teething stage, there is fear and ambiguity over the safety & security of hookless rims, especially at higher pressures.

A big stumbling block is the number of cobbled together road tubeless solutions, significant variance in tolerances from one rim or tire to the next, and anecdotal failures muddying the water.

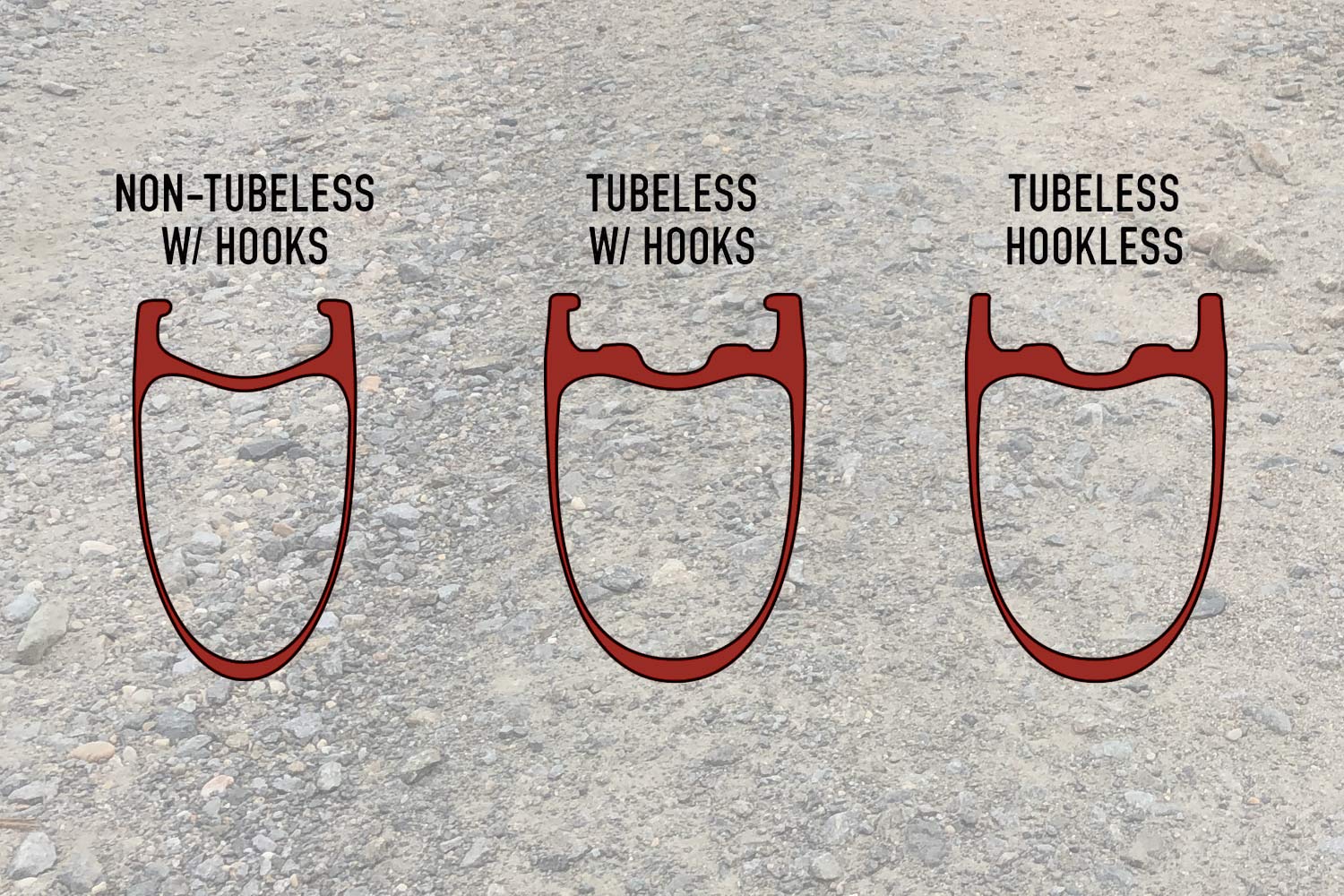

So, ENVE decided to go deep on what a hookless bead is, how it works, and what type of rider it is for. It isn’t an issue unique to their rims, and helps clear up why the entire cycling industry is moving (at times, slowly) in the direction of hookless beads for almost all tubeless rims.

TL;DR – How do hookless beads work?

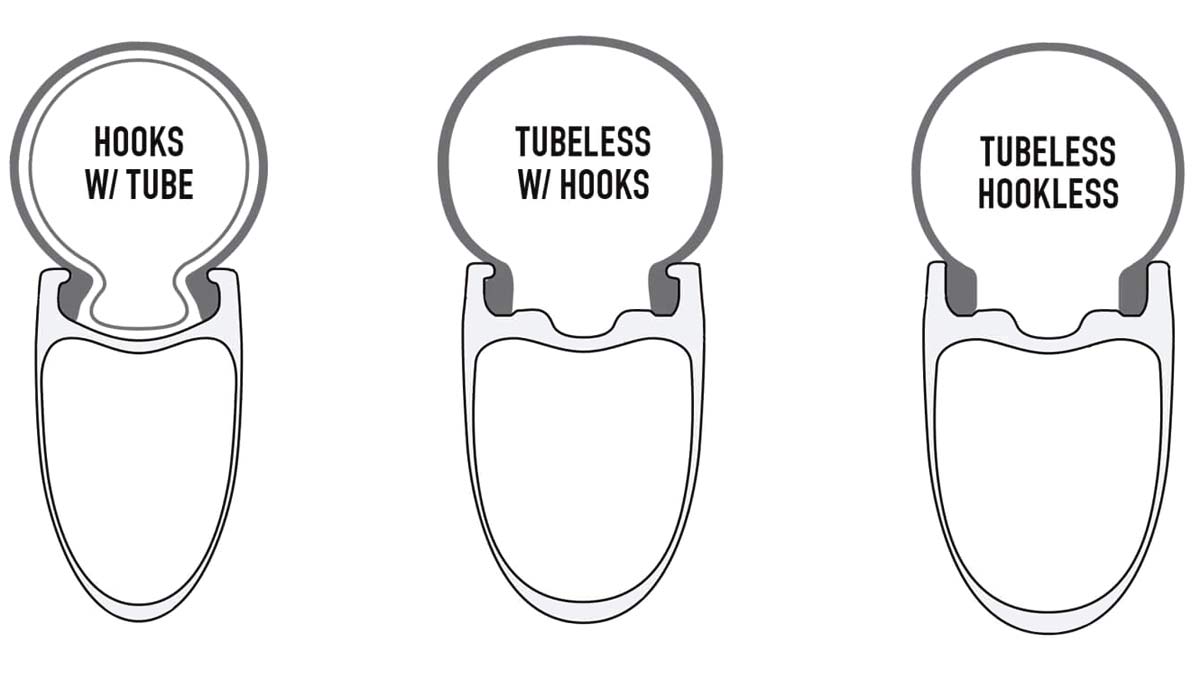

Here’s the nutshell version: First, just know that motorcycle and automotive tires have been using hookless beads forever. Those work because the tires can use ultra-strong wire beads that won’t stretch. They get away with that because a few extra grams don’t matter on motorized vehicles.

For bicycles, where every gram counts, the key is having the tire’s bead be designed within a certain diameter tolerance (standards are coming soon, but there’s a general consensus among most of the good manufacturers) and not stretching out of that tolerance over time.

Rims’ bead seats must also be within that tolerance. This creates a rim-tire system where both parts match each others’ shapes perfectly and don’t change during use. So, they’re able to provide a strong, airtight seal that also keeps everything in place even during hard cornering.

If these conditions are met, which they increasingly are as both rim and tire brands improve their manufacturing techniques and standards come online, then your hookless tubeless setup is as safe as any hooked setup.

Want the whole rabbit hole? Read the full blog post on ENVE’s website.