Pinarello made a special 3D printed titanium aerobar for their sponsored triathlete, Cameron Wurf. The uber-biker rode them to a 5th place finish at last weekend’s Ironman World Championship in Kailua-Kona, Hawaii. The bars will be available in custom sizing for any custom willing to wait the two-month lead time.

Pinarello custom 3D printed MOST aerobar for Ironman triathlete Cameron Wurf

Pinarello is making more and more developments for triathletes, and they’ve turned their focus to custom aerobars. Their latest project is a 3D printed titanium aerobar for Cameron Wurf, one of the top long-distance triathletes (something that was already done in 2015 for Bradley Wiggins’ hour record attempt). Cameron rode the bar to a 5th place finish at last weekend’s Ironman World Championship, with a bike split of 4:14:45 for the 112 mile course.

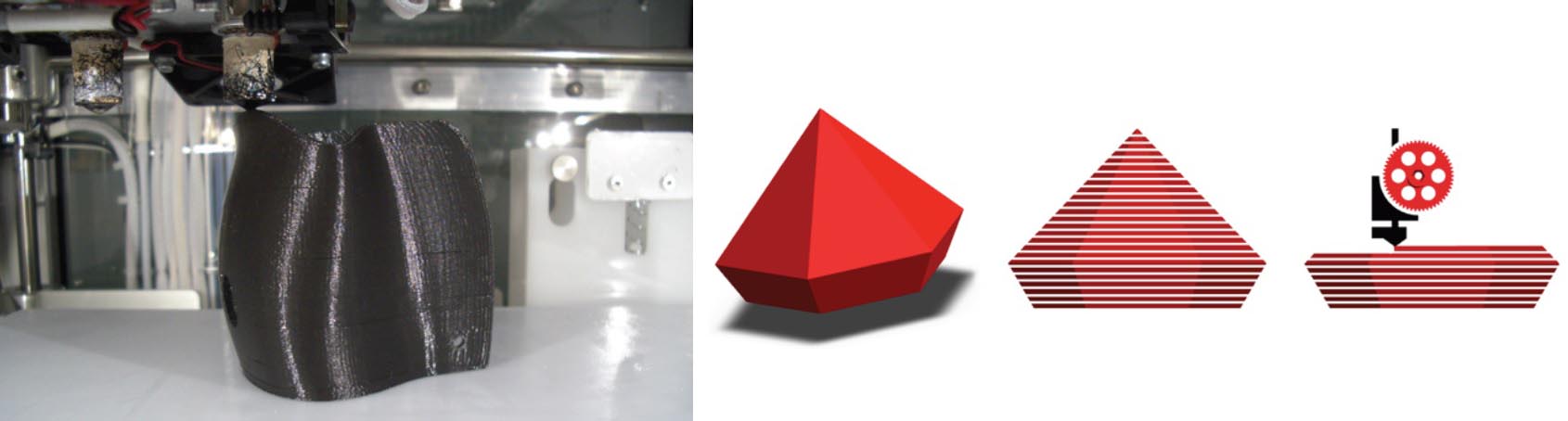

The bar was designed using CAD and 3D modeling, and manufactured with what Pinarello is calling Titanium Powder Bed Fusion Technology. The shape of the bar was determined with CFD analysis, and is said to be more efficiently made with 3D printing than CNC machining or carbon molding. Additionally, 3D printing allowed the removal of bolts from the system, reducing overall weight to 780g without paint.

The bars are for sale (with price TBD), and require a two-month lead time for manufacturing. Weight will vary based on the custom size of the bar.