Berd has only been selling their ultra light spokes for a few years now, but they’re quickly gaining attention. Recently spotted them on this crazy FRM build featuring all things Dyneema, Berd spokes are made from ultra-high molecular weight polyethylene, or UHMWPE. You can find the material in bulletproof vests, but it also works well for a spoke material – if you know how to use it.

Berd is the werd

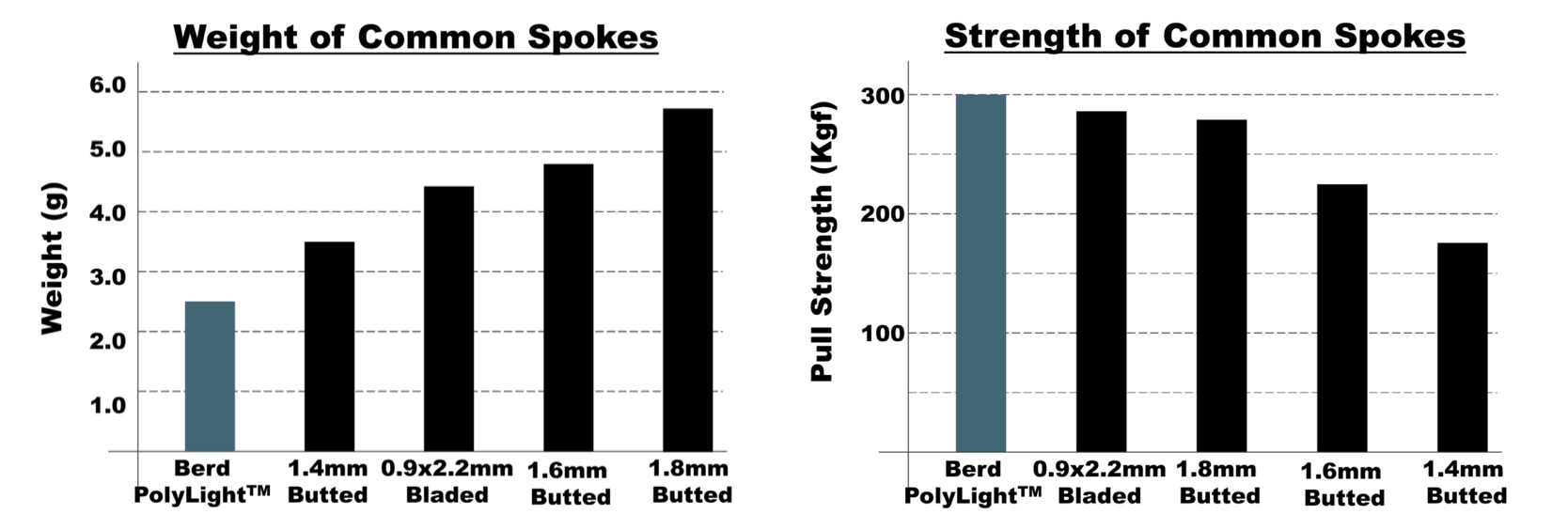

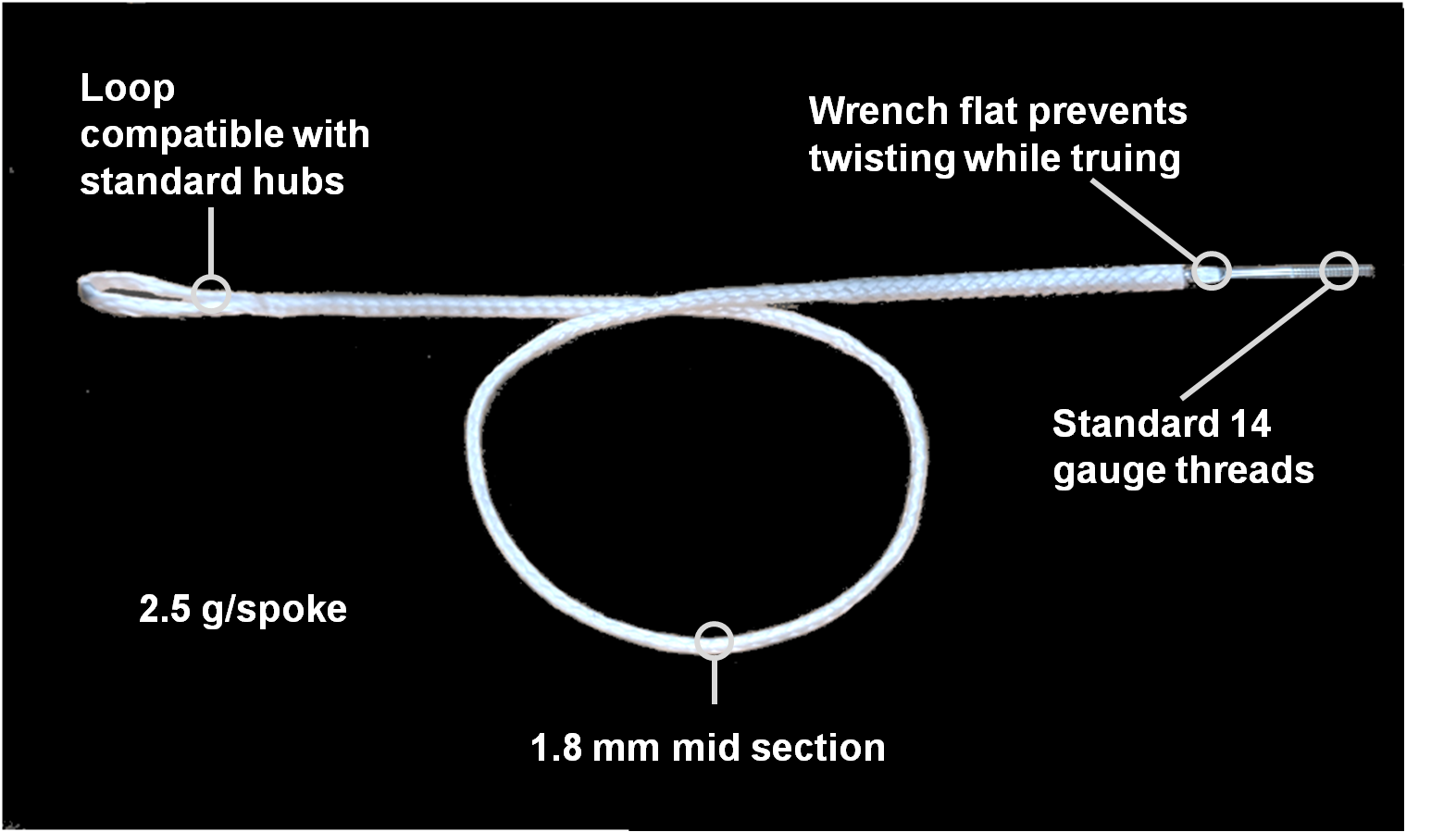

Compared to the usual steel spoke, Berd’s PolyLight spoke offers a number of advantages. For starters, the PolyLight is substantially lighter at just 2.5g per spoke. And since most of that weight is at the stainless steel attachment point on the end, the weight doesn’t change much per spoke length. Even though the PolyLight is much lower in weight, it’s actually higher in strength with 12 times the strength to weight ratio of steel. Atomik claims that in every test they performed, the Berd spokes had a higher breaking limit than anything else with co-founder Wayne Lee stating “The strength to weight ratio is truly impressive.”

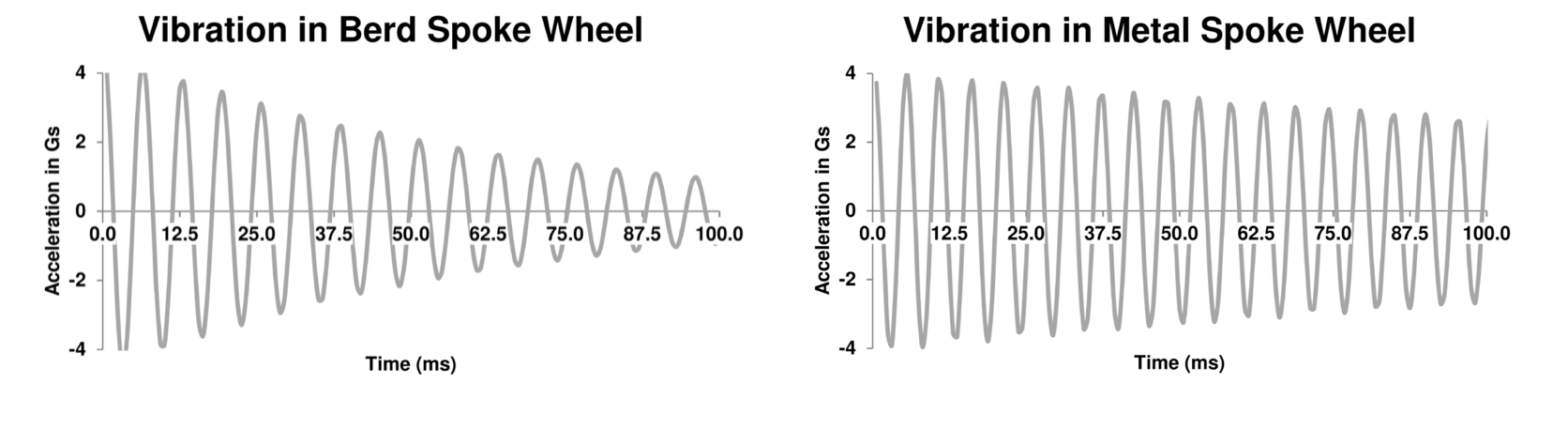

As an added bonus, the PolyLight spokes also seem to excel at vibration damping meaning that the wheels offer a better ride quality.

“We were blown away with the ride quality, especially on a hardtails and fully rigid gravel bikes,” says Lee. “We didn’t think there was a way to drastically improve the already impressive damping of our carbon rims, especially models featuring our HDP Foamcore. And steel spokes have always been such a given, that we didn’t consider the potential for other spoke materials and how they could improve weight, performance and ride quality—until now.”

Spoke construction

So if the material is so amazing, why hasn’t it been used before? Part of that equation is the construction of the spoke itself. Much of the strength and durability comes from the braiding of the UHMWPE material, but Berd wanted to maintain compatibility with most hubs and almost every standard rim. That meant adding a stainless attachment at the end that would would with standard spoke nipples, but that also meant finding away to bond the UHMWPE to the stainless end which is not easy. Berd figured it out though, and the result is a spoke that uses a standard 14g nipple that can be used to build most wheels. Like bladed spokes, the PolyLights have a wrench flat on the steel anchor point to keep the spoke from twisting when building the wheels.

Wheel builds

Berd spokes work with all j-bend hubs, tangential straight pull hubs, and some radial straight pull hubs though the attachment point at the hub varies slightly. Tangential straightpull hubs require no modification to use thanks to an insert that protects the spoke from damage, but j-bend and radial straight pull hubs need a little work. Specifically, you need to chamfer and polish the spoke hole edges to protect the spokes using the tools supplied by Berd. J-bend spoke use a loop that is inserted through the spoke hole, a rod is then inserted into the loop, and the spoke is pulled tight. It looks a little Flinstone-ish, but it works.

The wheels also require a specific build procedure which includes a 24 hour rest procedure between the last two of three tensioning sessions. This is due to the material “relaxing” by up to 50 percent the first time, then up to 25 percent the second time, before reaching their final length for the final tensioning.

Atomik Carbon Ultimate Wheelset

If you want to avoid all the work involved in building an ultra light wheelset with Berd spokes, you can purchase a pre-built set – like the new Atomik Carbon Ultimate wheelset. Atomik has been working closely with Berd to offer pre-built wheels and the ‘Ultimate’ moniker seemed fitting given the wheels’ impressive weights and ride qualities.

Weight

How light? Well, Atomik claims that wheelsets start as low as 1200g which obviously depends on your hub and rim selection. We’ve been playing around with two sets of gravel wheels which came in at 1361g for a 27.5″ set and 1393g for a 700c/29″ set. Note that these are both built with their XC33 rim which is 33mm wide external, and 26mm wide internal, so it’s a properly wide gravel or XC rim, and the wheels are all weighed above with tubeless tape and valves installed.

Berd claims that the addition of their spokes will drop 100-200g per wheelset, so not an insignificant savings.

Since their launch, Berd has been selling their spokes separately, only in white. But for Atomik, the stock color will be stealth black. Atomik also states that they will offer exclusive colors including red, blue, orange, and olive green – more on that soon.

Atomik will be offering their Carbon Ultimate wheels in both Gravel and Mountain builds, and in 650b or 700c/29″. Stock configurations will include Industry Nine hubs with Boost Hydra for MTB or Road Torch for gravel. Impressively, the wheels will sell for $1,699 – which is eyeopening considering the spokes alone typically sell for $600 per wheelset. Custom rim and hub configurations will also be offered through Atomik or your local bike shop.

First Impressions

I’ve had a few rides on the Carbon Ultimates now, and each time I couldn’t help but think the ride was a bit smoother than with other carbon wheels. That bodes well for their performance claims, but for better testing I’m planning to mount them onto a rigid gravel bike with back to back testing with another carbon wheelset. Ultimately though, they already deliver on weight, and as long as the prove to be durable, then they seem like they could be a winner. More soon.