We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question!

You asked, Rotor delivered. As expected, the questions for Rotor ranged widely from their 13 speed groups to the specifics about oval chainrings, and more. Check out their answers below and check out rotoramerica.com for more!

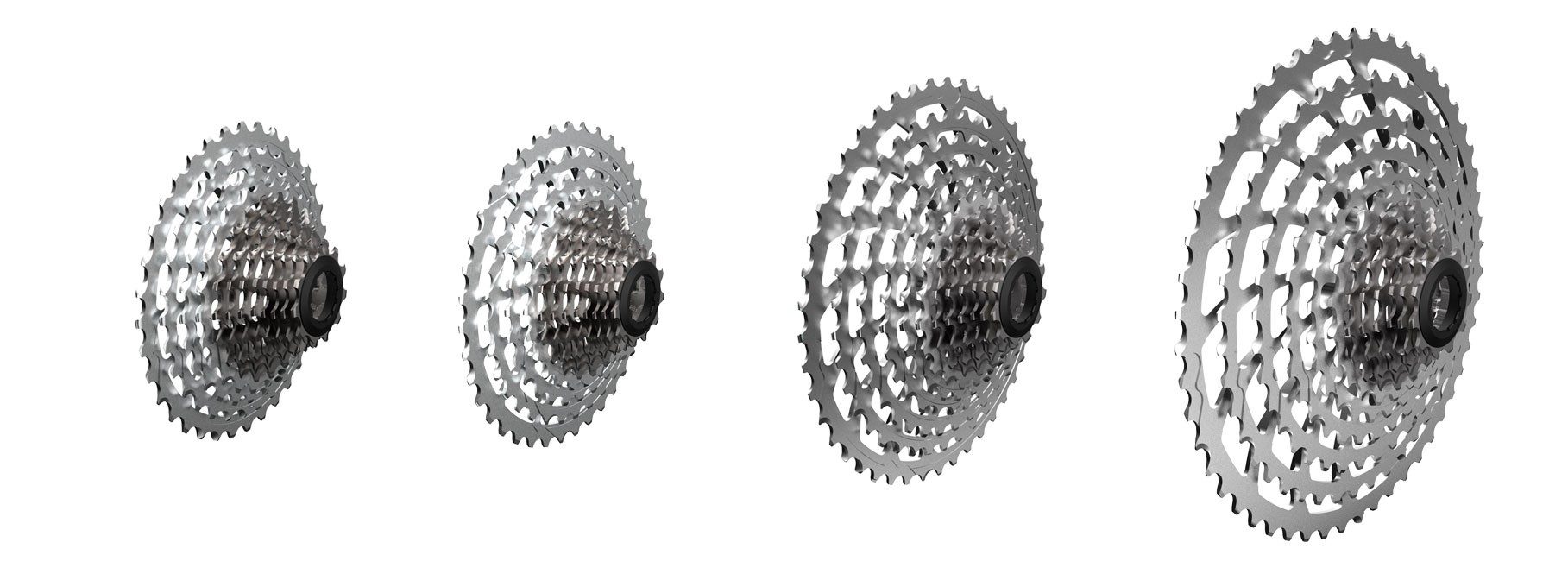

13 Speed 1x Groups

Are there any plans for a 13 speed, 10-42 cassette? – Owen

Rotor: Hi Owen, no plans at the moment. We worked with several of our pro teams and professional riders to look at power/cadence relations to develop our gear steps and found the 10-39 or 10-46 to be our optimal ranges to start with.

I have DT Swiss 240 hubs. Is there a freehub driver available so I can upgrade to new 13 speed Rotor MTB group? What hubs are currently compatible with your 13 speed cassettes? – Evan

Rotor: Hi Evan, while there is no way to update your freehub body to work with the 13s cassette, you can run a 12s version of the group with any HG freehub body (using the same derailleur and shifter, just limit the derailleur to 12 speed), including those DTs. The cassettes use 12s spacing on a standard HG-type freehub body and a 10t cog sitting outboard of the freehub body for the 13th speed.

10, 11, 12, now 13 speed – where do we go from here? Can we really just keep adding more gears to a 1x drivetrain, or will something have to give for the future? Does Rotor have anything in the works along these lines?

Rotor: It’s always hard to say where the future goes from here, but we would offer that the industry is always moving towards more gears with smaller steps between them, to reduce the effects of fatigue when riding. One of the great advantages of the 1×13 groupo is the decreased tooth count between many of the gear options, and of course the unavoidable small steps between gears. (As opposed to how a 2x system makes for big jumps in the cassette, since we’re always looking to avoid using the deeply-fallible front derailleur.) Rotor is always developing innovations to increase cyclists’ efficiency and offer a better ride experience.

Have you had any failures of the hydraulic lines for your drivetrain groups yet? – Sarah

Rotor: HI Sarah, so far we have seen excellent durability of the hydraulic shift lines. While it certainly is possible to damage or even completely sever a line, it’s about as likely as slicing into a hydraulic brake hose. One of the more interesting features of our 1×13 derailleurs lies in the ability to position the derailleur throughout the cassette by hand, in the event of a complete sever. With the shift indexing located in the derailleur, you are able to manually move the derailleur up or release it down the cassette even without a shifter or line attached. So even in the case of a catastrophic line cut, you will be able to move the derailleur by hand to select gearing while getting back home.

I’ve personally run the MTB group for a while now as with the line routed under the BB right alongside my rear brake hose. Plenty of BB hits and rocky riding and the shifting has remained undamaged.

Rotor makes lovely components in Spain. What’s up with sourcing carbon cranks from Asia? – Cheese

Rotor: At the end of the day, our goal is to create the best quality product for our customers. Our Spanish production facility is set up to create a premium market product from start to finish- in aluminum. We source our carbon layup out of an expert facility in Taiwan, while the aluminum crank parts, final crank production, and finish work are done in our Spanish factory.

Power Meters

When running an oval ring, are there any effects on power meter readings? Sometimes I see peak power numbers on my MTB that make me think I need to send files to pro tour teams, but then I look at my FTP and I’m brought back to reality. – Travis

Rotor: Hi Travis, Oval rings can affect certain power meters readings, primarily depending on the rate of data sampling. ROTOR uses the highest rate of data-read in the industry at 200 points per second, in order to provide riders with the most accurate data possible on round or oval rings. We also use all of that information to make a real-time spin scan on the INpower phone app & software, which can run as a diagnostic on oval ring positioning.

As for pro-team peak power data, it is certainly possible especially on the mountain bike, to see larger spikes in power data. Due to the often-punchy nature, think grunting over a tough uphill rock, you may see a momentary spike in your power data. Take a look at your 10s and 1-5m power data, depending on how those look you may still have your application ready to go!

I have a bike with a PF86 and I am wondering if there is a way to use the twinpower (2INpower) meter on the bike? – Efrain

Rotor: Hi Efrain, This is an easy setup, we offer our 4130 bottom brackets to let you run any of our 30mm road cranks in a PF86/BB86 frame (Think Giant and Canyon) as well as any of our 30mm MTB cranks in BB92 shells.

SRAM AXS Compatible Rotor Chainrings?

Will Rotor be adding an oval SRAM AXS compatible double chainring set? – Chris

Will Rotor have road DM double ringsets that work for SRAM AXS (road)? That means 13 tooth difference between the inner and outer ring AND teeth shaped to work with the SRAM 12sp FlatTop chain. – Mark

12 Speed Chainrings for SRAM Red AXS – when is it coming? – Tobias

Rotor: We will have 48/35 AXS chain compatible rings available in late January.

What is the cog spacing on the Rotor 12 speed cassettes, such as the 11-39? Are they compatible with a SRAM 12 speed drivetrain using an eagle derailleur and Red AXS shifters? – Ron

Rotor: Our cassette spacing is compatible with other 12s derailleurs on the market, so yes you would be able to run the Eagle derailleur and chain with our 11-36, 11-39, and 11-46t cassettes. Wider ranges may be possible but you will want to ensure your derailleur is able to handle the tooth count spreads and larger cog sizing before trying it out. Our 1×13 derailleur will accommodate our 10-52 and 11-52t cassettes.

What’s with Oval Chainrings?

The old Rotor Box crank system allowed the two cranks to move at different speeds, right? What was the concept behind that, and did that somehow translate into the idea for oval chainrings? – Peter

Rotor: Hi Peter, The Box system was really quite a cool concept if not a bit over engineered for the end goal. The idea behind both oval rings and the box system is an increased efficiency for your pedal stroke by minimizing the time and effort spent in your dead zone, the top and bottom of your pedal stroke. The Box system did so by using a set of cams to kick your trail leg over the top of the dead zone and ensure your cranks could never both be vertical at the same time.

Q-rings accomplish a similar goal of lessening the time and effort in the dead spot by decreasing the overall lever arm by clocking the smallest radius of the oval with your time at 12 and 6. Placing the largest radius of the ring at your peak power output, we seek to maximize the amount of work done when you have the most potential.

This link is a great resource to Q-rings of both advantages and setup guides.

Why are there so many different chainring profiles – oval, squoval, elliptical, etc. Does the shape really have that big of a difference on the performance? – Rich

Should everyone be riding non-round chainrings? – Rich

Do all non-round chainrings attempt to accomplish the same thing? – Rich

Rotor: Hi Rich, To broadly answer your question, yes most non-round rings all look to accomplish the same goal, decrease the amount of work done in the dead spot and increase work done in the power phase. There are differences in bio-mechanical interpretation that leads to the various shapes that you see from the manufactures of non-round rings.

We offer our rings with the adjustable chainring position (OCP) function and power meters to help riders properly clock the Q-rings to work best for the rider.

Editor’s note: For more on the science behind oval rings, check out Rotor’s white paper here.

Got a question of your own? Click here to use the AASQ form and submit your own question!