It is safe to say that Utah-based Mercury Cycling have one of the most rad-looking enduro wheelsets currently available on the market. The wild-looking silver-striped X1 Enduro Wheelset features a patent-pending Fiber-X composite material, which Mercury claim to be twice the tensile strength of hi-modulus carbon fiber, while also being capable of damping major impacts. With a price tag of $1,899, this enduro wheelset should provide an excellent ride feel and be bomb proof, right? For the 2019 race season, I got my Trek Slash enduro race bike rolling on a set of these 29er hoops, with the all-new Mercury Axis freehub with XD Driver. Before diving into the highs and lows of the review, let’s take a look at the Tech. There is a lot of it!

Mercury X1 Enduro with Fiber-X Tech

Not to beat about the proverbial bush, let’s get straight to that flashy silver-stripe. That’s the Fiber-X carbon composite which we still don’t really know anything about. Mercury say this composite adds an impact absorption characteristic to the wheel, with 2x the strength and 4x the damping properties of High Modulus Carbon. Just like a bullet proof vest absorbs the impact of a bullet, the Fiber-X composite adds strength to the rim and absorbs the energy from any impact or trail noise. On testing, Mercury say their wheels fared as well as the new Santa Cruz Reserve wheels, and were durable enough to withstand a double impact of 120 joules at the same location. Pretty impressive when you consider that the industry standard is just 80 joules in one hit.

In addition to the Fiber-X vibration damping material, the X1 Enduro rims are themselves formed with a rubberized resin. This engineering, borrowed from the airline industry, has been employed for durability purposes, protecting the rims during harsh impacts.

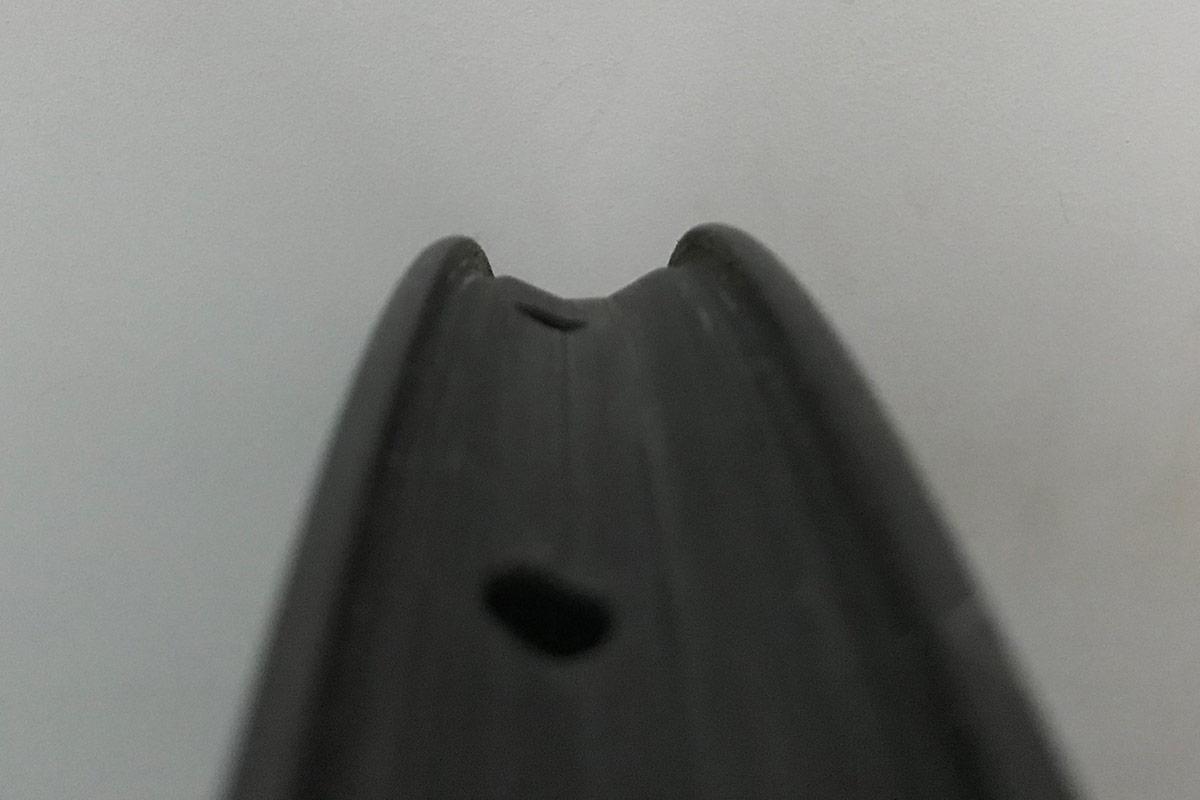

An asymmetrical rim profile is a tried and tested design to improve wheel stiffness as it allows for equal spoke lengths, and therefore tensions, on the drive and non-drive sides. Not being fans of the aesthetics of asymmetrical rims, Mercury have taken a slightly different route to attain the desired wheel stiffness. Notice how the rim has a straight top and straight sides. These 30mm internal width (38mm external) hookless carbon rims are symmetrically trapezoidal in profile, which is said to efficiently transfer energy from impacts taken at the rim edge, down to the Fiber-X composite spoke area. While the rims themselves are symmetrical, it is the spoke hole drilling that is offset allowing for spoke tensions to be almost equal on the DS and NDS. It also allows for the spokes to sit at a wider bracing angle for added lateral stiffness without the addition of weight.

Twenty-eight double-butted Sapim Race spokes leave the Mercury Axis hub and insert into brass Sapim Alloy nipples at a triple-butted reinforced nipple bed – the carbon fiber has stepped reinforcement here for added strength where the spokes pull on the rim.

Mercury Axis Hubs

The 29″ X1 Enduro rims are laced up to Mercury’s Axis BOOST 15x110mm front wheel hub, and 12x148mm freehub.

The Axis is Mercury’s proprietary freehub, for which they have made available both XD Driver and HG freehub bodies. It is a sealed bearing assembly with 6 triple-stepped pawls providing a short and fast 3.5 degree engagement with three pawls engaged at any one time. Each pawl sits on its own leaf spring with the triple-step helping to dissipate torque over a wider area, reducing the load at any one point and increasing durability. The pawls themselves are quite wide, measured at 5mm, dissipating force over a wide area, which should help the whole system to function under high torque.

The hub creation process starts with cold forged aluminum block of 6000 series aluminium alloy, chosen for its strength and ductility characteristics. It is CNC milled using a CNC machine that operates over five axes, hence the name Axis. This allowed Mercury to machine in “hard to get” spots. The axle is 17mm in diameter, 2mm thick and is made of 7xxx series aluminium alloy.

Mercury X1 Enduro: Testing

On their arrival, the true of the X1 Enduro Wheelset was checked, and we were not left wanting. Check out the short video below to see the wheels rolling in a Park Tool Truing stand, and to hear the Axis freehub doing its thing. The front wheel weighed in at 810g, while the rear with XD Driver weighed in at 950g, bringing the total wheelset weight to 1,760g. This is just within the claimed weight of 1,725g (+/- 2%) and a good 125g lighter than similarly priced carbon wheels from Crank Brothers, the Synthesis E11.

As you can see, the wheels arrived tubeless-ready, with the rims very well taped. I fitted MSC Gripper 2.3″ tires to the hookless rims, tubeless. These rims are fairly deep at 24mm; not a problem when you’ve a workshop-grade air compressor on-hand, a bit more of a mission when you’ve only got an Airshot available on race morning. You’ll need valve extenders.

So, how do they ride?

Supremely well, actually. There’s an elephant in the room, but we got a 4-month incident free period out of these wheels, so bear with. The 3.5 degree hub engagement is plenty fast enough. So quick that I now don’t even consciously think about that as a factor when riding. The quick engagement is particularly helpful for technical climbing, giving you propulsion exactly as and when you need it to get up and over rocky features.

During the 5 month test period, July to November, the X1s were my sole wheelset. During that time I raced five UK enduros, including the Naughty Northumbrian, with a wild scree-slope stage, and a Scottish Enduro Series round at Fort William, with its 10-minute long granite rock Top Chief track. I also hit the Fort William World Cup track on these wheels – not the massive senders, but the infamous wood section rock garden, and the 4-5 ft drops on the top section. The wheelset held up flawlessly on all of the above, and also on a trip to Scotland’s rockiest trail centre, Laggan.

The Mercury X1s track remarkably well through turns, and the lightweight rims make changing direction effortless. There was nothing about the ride feel of the wheels that would lead me to call them too stiff, but they certainly weren’t too compliant either. Checking the true of the wheels towards the end of the test period found that they ran as true as the day they were fitted at BSpoke Cycles, and as round. Having never touched a spoke throughout the whole test period, the tensions were still as new.

At around the 4-month point, the freehub and hub shell bearings were rough, and the freehub was sticking on the back pedal. On inspection, the freehub grease actually looked remarkably clean given the sloppy conditions it had been subjected to, credit to the 2 seals at either end of the hub.

On closer inspection, it became clear that the freehub sticking was caused by a wandering hub flange (pictured) which had migrated inboard towards the hub shell and was pressing too hard against the main hub seal. Freehub bearing replacement was made harder than necessary by the presence of a machined circlip recess on the inner surface of the freehub body – the old bearing kept slipping into the recess when being pulled out. As for pushing the new bearings back in; the plastic cover that stops the hub flanges from moving about too much was easily cracked as the new bearing was pushed back in. This didn’t affect the functioning of the freehub at all, however.

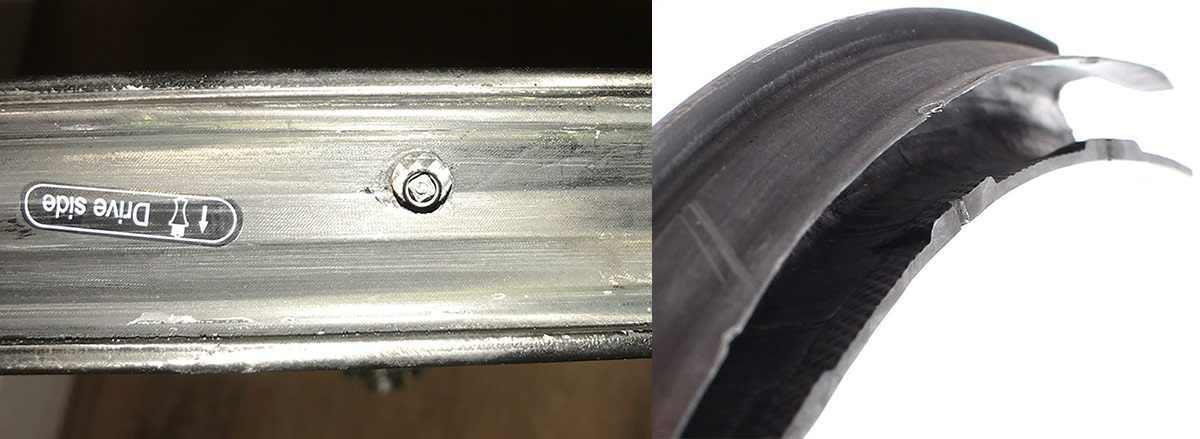

The Broken Rim

The rim failed where I least expected it to; on my local DH trails at Innerleithen, where the tracks are 99% loam. The rear wheel landed awkwardly on a rock from a short bunny hop, at speed I grant you. A classic shotgun noise and the dreaded hiss ensued. I was running an MSC Gripper 2.3″ Super Shield tyre tubeless, with no rim protection at around 20 psi. You may think that low but I weigh only 60 kgs soaking wet. We got in touch with Mercury to chat about the rim crack; they said they offer customers a $150 crash replacement policy, shipped.

Pricing & Availability

The Mercury X1 Fiber-X Enduro Wheelset will set you back $1,899, but Mercury offer a 15% discount to those who subscribe to the mailing list. 27.5″ or 29″ rims are laced up to the Mercury Axis freehub, with either an XD or HG Driver. Mercury also support all current axle sizes. A 2-year warranty policy against manufacturer’s defects is extended to the original owner only.