BlackHeart Bike Company is a new builder based in Venice Beach, CA. They’re launching with a single titanium allroad frameset, built for folks who ride 50/50 on/off-road. With short chainstays and ample tire clearance, it’s designed for anything from spirited group rides to light XC.

BlackHeart Bike Company titanium allroad bike

The ‘Allroad’ category doesn’t seem to have any clear definitions, but most can agree that it falls somewhere between road and gravel bikes. Standards can vary, and most don’t use suspension forks, but the goalposts are always shifting (with many Allroad bikes having more tire clearance than gravel and CX bikes from just a few years ago).

Why did BlackHeart come about?

“BlackHeart Bike Company was born out of a feeling of disillusionment with the mainstream cycling industry. We got tired of being told that our bike was never light, fast, or stiff enough. That if we really wanted to ride we needed to spend more money.

We spent two years prototyping a frameset bike that looks beautiful, feel like an extension of your body, and can handle almost any adventure.”

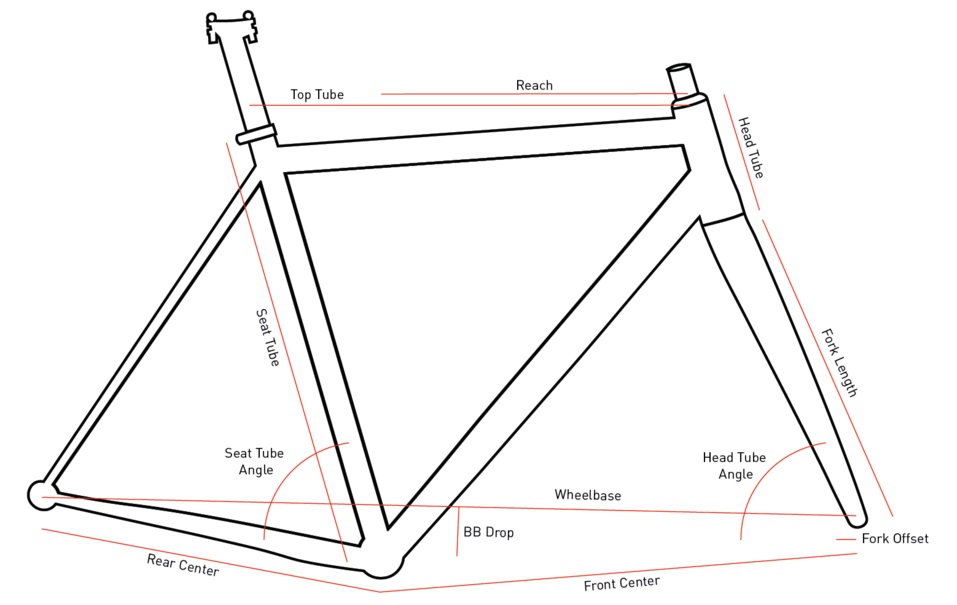

The 3Al-2.5V frame uses double butted tubes and a tapered head tube. The proprietary carbon fork features internal cable routing and straight legs.

A variety of ports allow for internal cable routing.

BlackHeart opts for a PF30 bottom bracket shell, and maximum chainring sizes of 50/35, or a 44-tooth single ring. They also offer free installation of BBinfinite bottom brackets when purchased with a frame.

Flat mount brakes and a replaceable derailleur hanger round out the rear end.

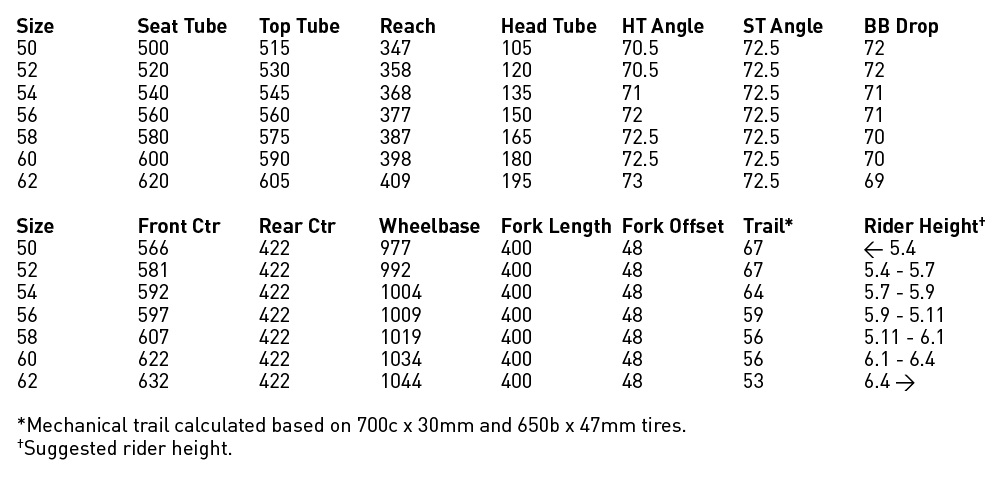

Seven sizes are offered. Despite the relatively short 422mm chainstays, the bike allows up to 700 x 37mm or 650b x 47mm tires.

BlackHeart offers a bare frame for $2,300, or a frame, fork, and seatpost for $2,750. Frames include a lifetime warranty against manufacturer defects for the original owner.