Like many (most?) businesses out there, those in the bike industry are facing great uncertainty in the face of the COVID-19 crisis. With entire countries on lock down where cycling for sport is now illegal, and more U.S. states seeing shelter-in-place orders, many have had to hit pause on their daily operations. That doesn’t mean that every company has had to send their employees home, however. We’re starting to see more and more companies pivoting to manufacturing a completely different family of products. From face masks and face shields to ventilator parts, the cycling industry is stepping up in big ways to help out however they can.

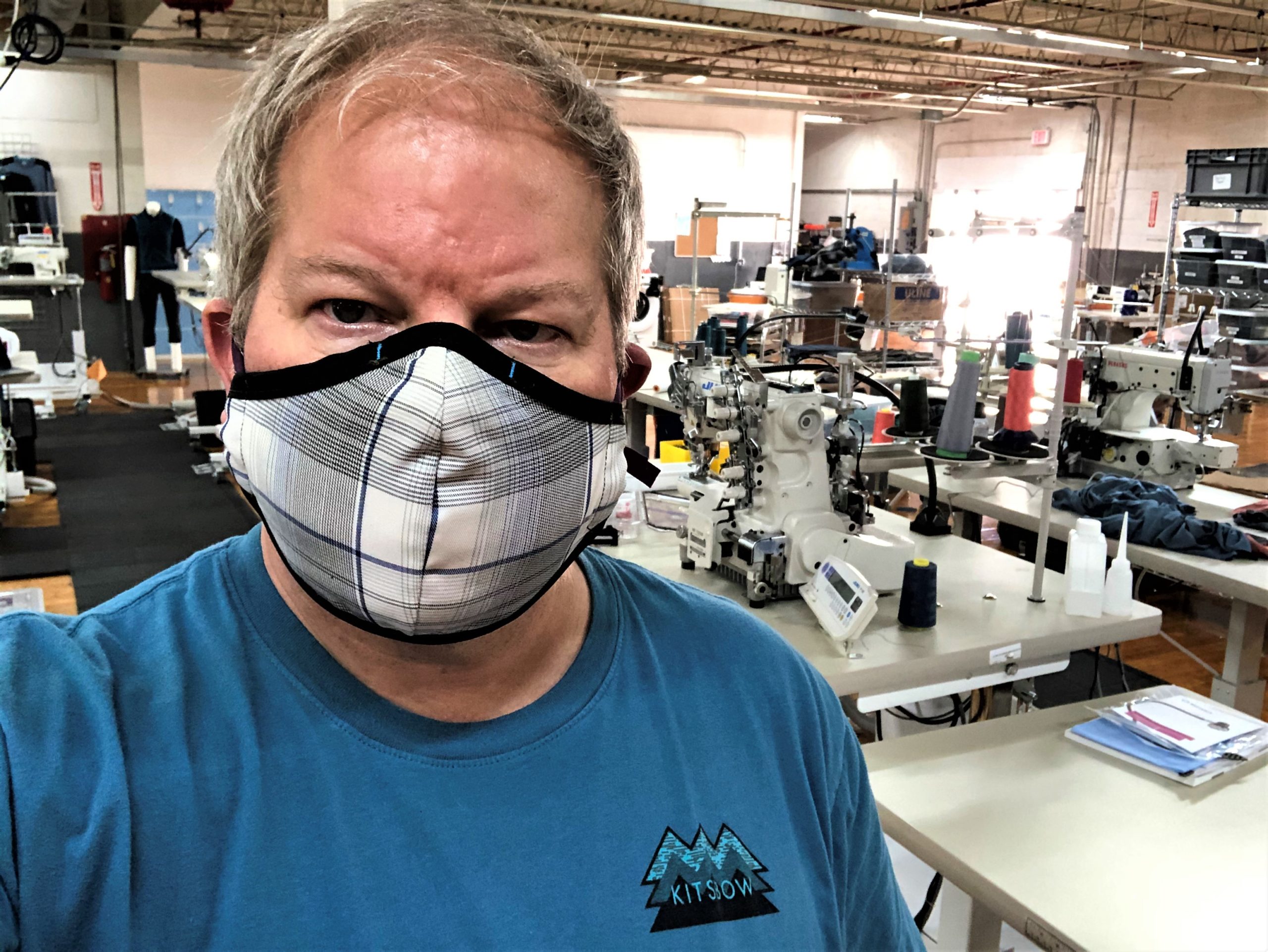

Kitsbow

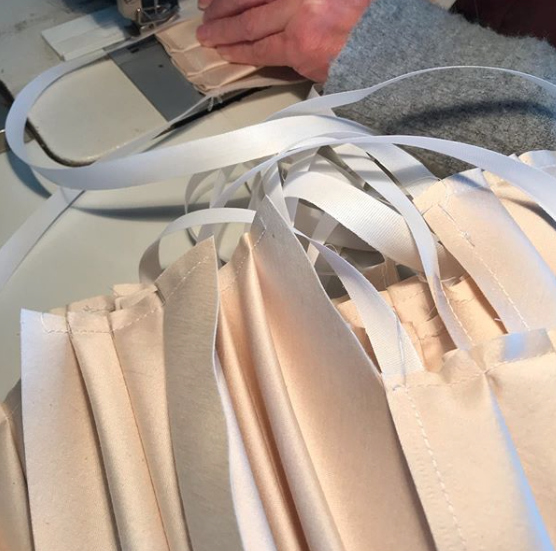

Masks seem to be one of the most needed products at the moment, and it seems that clothing makers are uniquely suited to switching gears for production. Kitsbow is also making face shields based on a Makerspace design. Note that Kitsbow has completely shifted their production to these new items and while you’ll still be able to order any of their bicycle related pieces, the shipping will be delayed as the company focuses on this new challenge.

Press Release: Kitsbow, a premium bike apparel brand based in Old Fort, North Carolina, decided to pivot its apparel production to make face shields for first responders as well as reusable face masks.

Kitsbow founder, Zander Nosler, is a Stanford University graduate and remains well-connected with the Stanford Design School alumni, which shared a design of a face shield from the University of Wisconsin-Madison Makerspace. An initial design was created by Kitsbow last Thursday, and after collecting feedback and design tweaks from local first responders, Kitsbow kicked mask production into high gear, with its first shipment going out today.

The first shields are going to Asheville-based Buncombe County Emergency Management and Burke County Emergency Management and the first masks are going to a medical clinic in Salem, Oregon that is cleaning disposable masks in order to reuse them.

Kitsbow is currently selling the masks at-cost to local first responders and medical staff, but plans to distribute internationally as they make more. Using raw materials on-hand, Kitsbow will continue making the masks and shields as long as they are needed. This also allows Kitsbow to keep its employees paid and working, unlike so many businesses throughout the country.

Kitsbow’s primary focus remains the health of its staff, families, and community.

Orucase

Similarly to Kitsbow, Orucase has been making their own reusable masks for the general public out of materials they already have on hand. These will be sold for $20, and the proceeds from each sale will go to provide 20 masks for the medical community which will be made from surgical-grade materials which are currently being acquired.

The consumer masks are made from washable and breathable cotton with a three layer non-woven activated carbon filter element. Each mask includes 14 filter element replacements which are recommended to be replaced daily.

Santini

As reported by the UCI, Santini is shifting from Rainbow jersey production to reusable face mask production.

From UCI/Santini: The Lombardy province of Bergamo is the Italian epicenter of the dramatic spread of the COVID-19 pandemic, with thousands of cases and hundreds of deaths. But for many years the Orobic population has been known for its tenacity and stubbornness, and its ability to react with great intensity and solidarity. A number of local organisations have put themselves on the front line of helping the community. Among them, the well known Santini, based in Lallio.

The historic brand of cycling and triathlon technical clothing – which has worked in partnership with the UCI for more than 30 years and produces the UCI World Champions’ rainbow jerseys – is ready to convert a large part of its production chain to the practicalities of addressing one of the most urgent issues in today’s emergency: the shortage of protective face masks.

Within just a few days Santini prepared a high quality prototype that is currently being examined by the Politecnico di Milano (Milan Polytechnic) to ensure it obtains all the necessary certifications ahead of starting production in large quantities as soon as possible.

We discussed the initiative with Paola Santini, the company’s Marketing Director, sister of the CEO Monica and daughter of the founder Pietro. “The idea was born on Monday 16th March,” she told us, “when the new standard for protective devices came out, with the chance to create a sort of self-certification on the masks based on a series of criteria established in a recent decree. The aim was to give the opportunity to other manufacturers to create a product that can no longer be found. I looked at my sister and we said to each other: ‘Let’s see if we can do something’. We live in the eye of the storm, we feel this emergency on our skin.”

Santini worked closely with Sitip, another Bergamo-based company: “They are one of our longest-standing suppliers. We selected the right fabric together and we consulted with doctors and local ATS (Agenzia di Tutela della Salute – Health Protection Agency) to design the best shape and structure. In a race against time, we sent our best prototype to Milan Polytechnic and meanwhile we have continued working on other solutions. We conducted various internal checks, but we wanted to obtain more rigorous and scientific tests including the microbiological test, something that we could not perform by ourselves”.

Reflecting the dramatic situation in Italy, Paola Santini explained: “The rumour about our project spread and we received hundreds of calls not only from the press, but also from hospitals, charities and the Protezione Civile (Civil Protection). The situation is desperate, in the province they need masks even without certification. For example, the Intensive Care Unit of Sondrio are still waiting for stocks of masks that have been held up somewhere, since all customs are closed, so they organised a network with local authorities and cotton companies for urgent supplies of new ones.”

What is the difference between the most common face masks and the model Santini is working on? “Our prototype is reusable, sterilisable and washable up to 90-95 degrees with the integrity of the fabric being guaranteed for use up to ten times. It is made of dense and very compact polyester fabric, with a treatment called “Acqua Zero” (Zero Water) which makes the mask completely waterproof.

“To give more value and effectiveness we used a double layer of the fabric. In addition, we have worked to create a close fit to the user’s face, so we included a nose support and elastic bands that reach the back of the head and not only the ears. “This solution gives several benefits: it fits perfectly on the most pertinent part of the face and it guarantees greater comfort even after hours and hours of uninterrupted use, for example for those who are still working during the emergency”.

Santini estimate they would be able to produce 10,000 masks per day and have already received requests for more than 100,000, although the demand appears likely to increase exponentially. They will give initial priority to Bergamo, that is the most urgent task, then to the province and then the rest of the region and the country. Above all, Santini are ready to do this for free: “We don’t earn a penny. We decided to put a price that only covers the cost of the technical fabric – high quality and Italian – and production. One of the reasons why there are no more masks in Italy is because nobody does them, they are not profitable”.

Santini have opened up a new pathway of solidarity, based on clear ideals: “We just want to help; producing masks is not our original job and it wasn’t easy to set up the project. But here in Bergamo we are hard workers and we all have a friend or a relative affected by the virus. We don’t know how and when the emergency will end and what will happen next. But with these kinds of initiatives we believe we can give hope and inspiration to other organisations to follow us. Just in Bergamo there are already two other companies ready to convert”.

Brassi Industry/Kalas Sportswear

From our Czech office comes news of similar efforts by both Brassi Industry and Kalas Sportswear. Brassi Industry is making and selling a reusable face mask made from Evolon material for €2, while supplying them for free to local institutions and individuals in need. While Kalas Sportswear has currently manufactured 9,452 face masks which have been supplied to firefighters, paramedics, doctors, and other organizations in need.

Chrome

Chrome is taking a slightly different approach and asking you to help out. They’re providing the patterns, instructions, and distribution assistance to get masks to those that need them – like health care workers who have resorted to using bandanas since masks simply aren’t available.

PORTLAND, OR – March 24, 2020 – As reported by the NYT, CNN, and others, there’s a nationwide shortage of protective masks for healthcare professionals. With the news of doctors willing to use bandanas as protection, and an influx of requests from doctors at private practices asking for help, Chrome Industries is using its own resources and mobilizing makers to rally and sew masks for the front line of healthcare.

Chrome is actively promoting the mask making effort, providing home-based makers with the design, pattern, and instructions to make masks at home. Anyone interested in supporting the project can email support@chromeindustries.com to get the information.

“The lack of masks, gowns, and eye protection is limiting the ability of medical workers to fight the COVID-19 — and putting their lives at risk. There is a basic need on the front lines, and our community has an opportunity to help,” said Steve McCallion, President of Chrome Industries, “We all can help make a difference.”

FMB

Tubular tire maker FMB seems to be making masks out of… tubular tire casings? According to the caption on their instagram post, “the 2 layers of natural latex will be an obstacle for COVID-19.”

Scicon

Italian bike bag & eyewear maker Scicon is shifting their textile production capacity over to making much sought-after face masks, and their entire sunglasses production over to manufacturing one model of clear-lens protective eyewear. First developed to provide FFP1 protection for local organizations in need, Scicon is still waiting for medical use certifications from the Italian government (which is in process) before they can be provided institutionally.

In the meantime, in an effort to help keep their employees working (and paid) at a time when their regional economy is being devastated, Scicon is permitted to offer the ‘FFP1-level’ masks & their glasses for commercial sale as “filtering screens” to private individuals around the world who are trying to source their own personal protection.

Mussolente, Italy, – 25 March 2020 – SCICON Sports, global leader in the production of cycling bags, has pivoted its production of bags and protective eyewear in light of the current pandemic to manufacture a selection of personal protection items that aim to support the improvement of public health.

Following the example of many other companies in the textile sector, SCICON Sports is joining the effort and has converted its entire production line to create protective respirator face masks and protective eyewear in response to the increasingly pressing request of companies, private entities and law enforcement agencies for protective equipment.

In addition to offering sports bags and protective eyewear, SCICON Sports also manufactures custom cycling clothing in-house under the Ftech brand (www.ftech.it) which has led to a wealth of experience and know-how in the field of apparel manufacture for over 10 years.

Located in Veneto, one of both Italy and the world’s most affected areas by COVID-19, SCICON Sports presents the first model of a protective respirator face mask following extensive prototype testing and the selection of various fabrics in collaboration with leading Italian fabric suppliers.

The new mask complies with FFP1 standards, even if it is not currently approved as such, as timelines simply do not allow rapid testing. An application with the Italian National Institute of Health has been made. As of now, SCICON Sports’ protective respirator face masks are considered as “filtering screens”, designed and manufactured on the basis of Article 16 Paragraph 2 of an Decree issued by the Italian Government on March 17, that authorises the production and distribution of filtering masks without CE mark and excludes them from prepossession of commercial standards.

In addition to the newly developed protective respirator face masks, SCICON Sports also offers highly protective AeroTech eyewear equipped with clear lenses, the same model that is sported by 3 World Tour cycling teams.

Claudio Fantin, Marketing Strategist of the ASG Group, which SCICON and FTECH are part of, said: “We decided to try our best to help with our team at great effort. We have been developing high-performance products for athletes for 40 years now and we are convinced that many others can protect themselves. Technical cycling fabrics are ideal for masks and sports eyewear are very effective screens for protecting the eyes from saliva. We admit that we are at war and we must unite to win the fight against COVID-19. We urge all apparel manufacturers to follow our model and we are ready to provide as much insight as we can to help, from drawings, data sheets and information on materials, to tips and suggestions for anyone that wants to follow suit.”

SCICON Sports has not confirmed its daily production capacity, as the supply of raw materials and potential closure of productions of suppliers remains uncertain and relies on the enforcement of the latest decree issued by the Italian Government to further reduce the impact of the pandemic. For more information visit www.sciconsports.com.

More Masks!

We know of at least one more face mask making operation that we’re getting the details on, but we’re guessing there are more that we have missed. Know anyone doing something similar? Let us know in the comments!

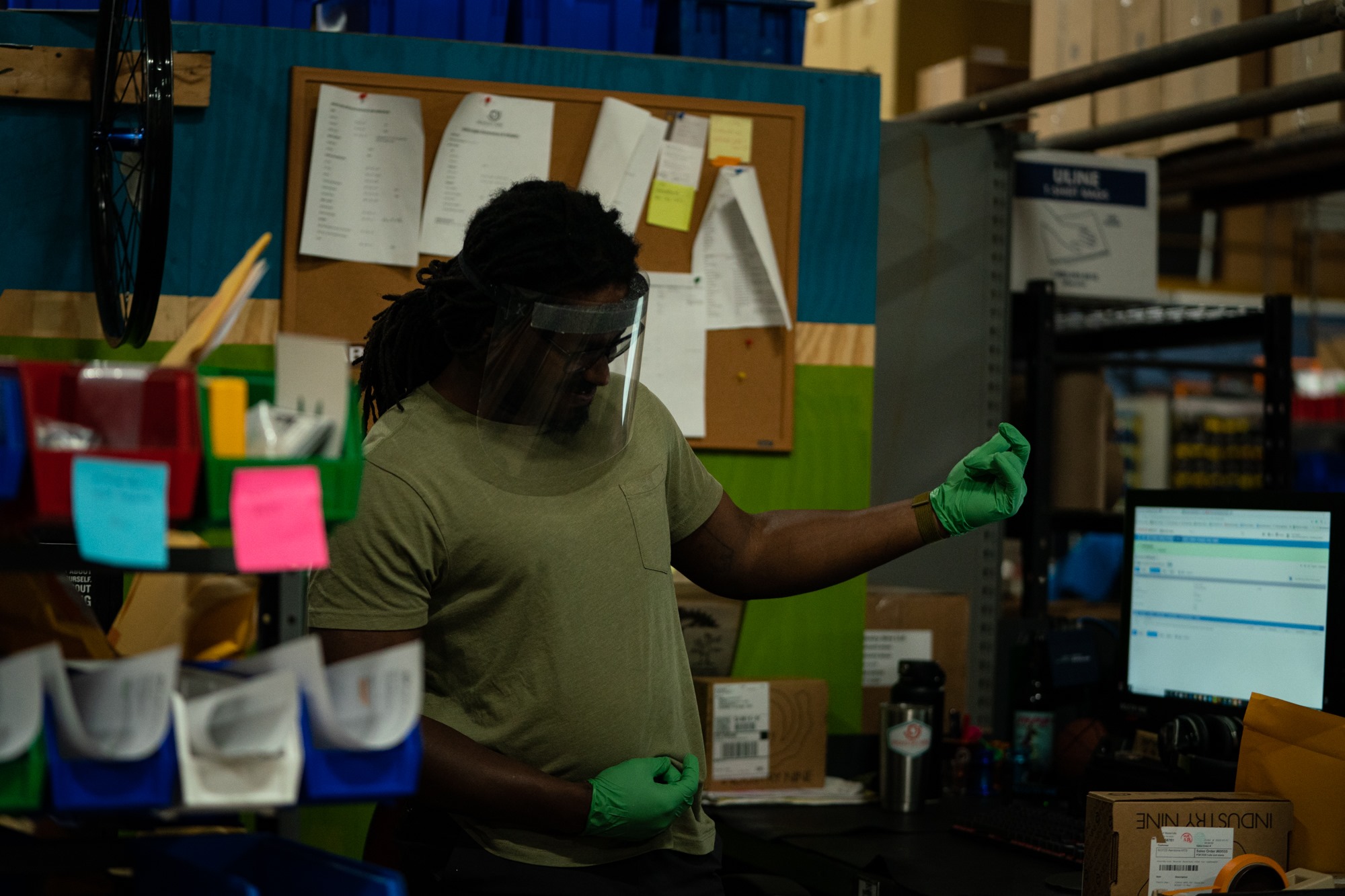

Industry Nine partners with Kitsbow, Watershed Drybags, and Oowee Products to crank out 1,000,000 protective shields this month

UPDATE: When we first posted this story, Industry Nine was looking for a way that they could use their manufacturing strengths to make a sizable difference. What they ended up finding was a way to partner with Kitsbow and two other North Carolina Based companies, Oowee Products and Watershed Drybags, to massively increase production of the reusable face shields that Kitsbow is now producing. Thanks to their proficiencies in large scale manufacturing and raw materials sourcing, I9 has been able to ramp up production of the shields to 10,000 per day, and they expect to have increased that to 1,000,000 shields this month.

Even with all of this, they’re still looking for ways to help out with ventilator part production as well, so if you have any contacts or leads, send them to theeffort@industrynine.net

Know of Other Companies Doing Awesome Things?

If you know of other companies that are helping to fight COVID-19 in a meaningful way, drop a note in the comments – we know that they’re out there, these are likely just the tip of the iceberg. Thanks to everyone for doing whatever they can in these extraordinary times!