At only 3mm thick, the Tatze Blade is part of an new concept where the pedal bearing is integrated into the crank. Traditional pedals house the bearings within the pedal, rotating about a spindle that often runs the full width of the platform. The size of the bearings has limited how thin, and by default, light, the pedal platform can be. A few brands have addressed this by moving to a larger bearing right at the crank arm, but few have modified the crankarm itself.

While this design certainly reminds us of the original FlyPaper pedals, Tatze Bike Components looks to have improved upon it with an even thinner pedal, without a protruding shoulder at the crank arm. Their “Integral Standard” houses the pedal bearing within the crank, meaning the platform can be much thinner. We are fortunate enough to have access to some images of the prototype.

Tatze Blade 3mm Pedal

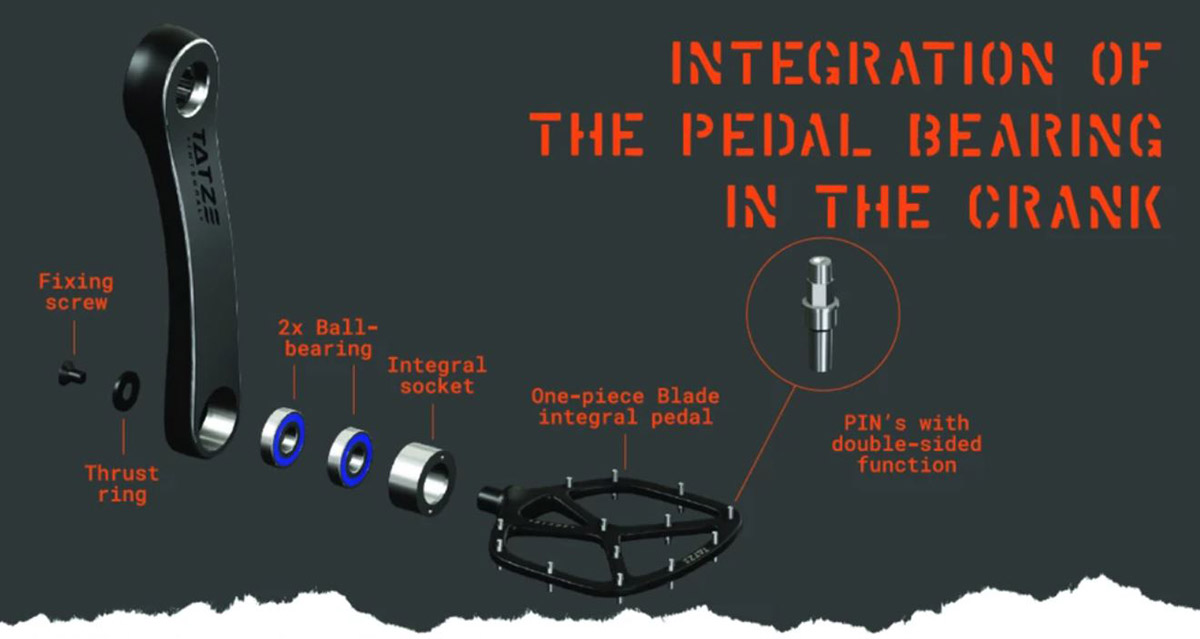

In the Tatze Integral Standard, the components of a pedal – axle, bearing including seal and pedal body – are rearranged, with the crank being included in this system. The bearing is integrated into the construction space of the crank, allowing for a one-piece design that is extremely thin. The need for a specific crankset to run the FlyPapers seemed to lead to their downfall, so it will be interesting to see how Tatze copes with a similar design.

Shown on an e-bike, this could be one of the best uses for the system where increased ground clearance is greatly appreciated. It also allows Tatze to easily manufacture their own crank arms where Momentum Bicycle was relying on modified crank arms from brands like FSA.

At 3mm thick (beating the FlyTraps by 0.7mm), the Tatze Blade undercuts everything that has existed before and sets a new standard. Such a thin platform evidently posed a problem for the mounting of pins. Tatze solved this by developing pins that thread all the way through the platform, protruding from both sides simultaneously. Just one thread is required to support two pins, effectively.

Not only will a 3mm pedal platform offer heaps more ground clearance leading to reduced pedal strikes, it will also lengthen the effective crank length. Whether this will increase pedal efficiency or not will very much depend on the leg length of the rider and their style of riding.

Details on the Tatze Blade are still thin on the ground. What we do know is that this product will be sold as pedal and crank together, as it is one system. It will be interesting to see what crank length(s) they offer, the longevity of this design and how easily serviceable they’ll be.

No claimed weight has yet been specified as Tatze are still in the prototyping phase of the design process. But, they do give a weight breakdown by material; 42CrMo4 150g, Titanium 100g, Aluminium 85g.

Tatze say they are currently in the middle of the development stage for series production and will use the summer for extensive product tests. They plan to present the entire system, i.e. crank plus pedal and probably a new and improved chainring holder at Eurobike 2020.