Last Bikes claim to have made the World’s lightest enduro mountain bike frame ever. The Last Tarvo’s carbon frame weighs just 2.08kg, almost a kilogram lighter than their already light aluminium frames. The Tarvo is a 160mm rear wheel travel carbon frame 29er, built around a recommended 170mm travel fork. Despite its svelte weight, the Tarvo makes no compromises on frame robustness, tested to ASTM standard and bike-park approved.

We have all the tech and details right here. First, a shreddit.

Last Tarvo

Last Bikes make no bones about it; when they began designing the Tarvo, their aim was to make the lightest enduro mountain bike frame ever. It was no accident. The Tarvo’s overall concept is functional lightweight. That is to say, they wanted to make a bike that was both fast and easy to control. The Tarvo isn’t simply an aluminium test frame made out of carbon. It is designed from the ground up using advantages of the material that “you can really feel”.

- Intended Use: Enduro

- Wheel size options: 29″ F&R, or 29″ Front 27.5″ Rear

- Frame Material: Monocoque Carbon

- Frame Weight (claimed): 2.08kg

- Rear wheel travel: 160mm

- Size Options: 165, 175, 185, 195 (rider height in cm)

- Bike Park Approved (5-year warranty)

- Retail (frame only): 3,599 €

The Tarvo is a full carbon construction with aluminium rocker. The rear end pivots about full complement stainless steel bearings from Enduro bearings in the dimension 28x15x7 at all highly stressed bearing points. The screw connections of the main pivot and rocker arm pivot are size M14 with titanium threaded inserts.

To give the seat stay an unobstructed flex and a clean design, the disc brake is attached to the inside of the chain stay. A PM180 mount uses inserted barrel nuts which can be easily replaced if the threads are damaged.

The frame features integrated storage space for a pump, spares, tools, etc. The lid features bottle bosses.

Cable routing is fully internal, guided through Bowden cables laminated directly into the down tube. This keeps things quiet and aids cable installation. A cable management system is integrated in the rear end.

Last Tarvo Geometry

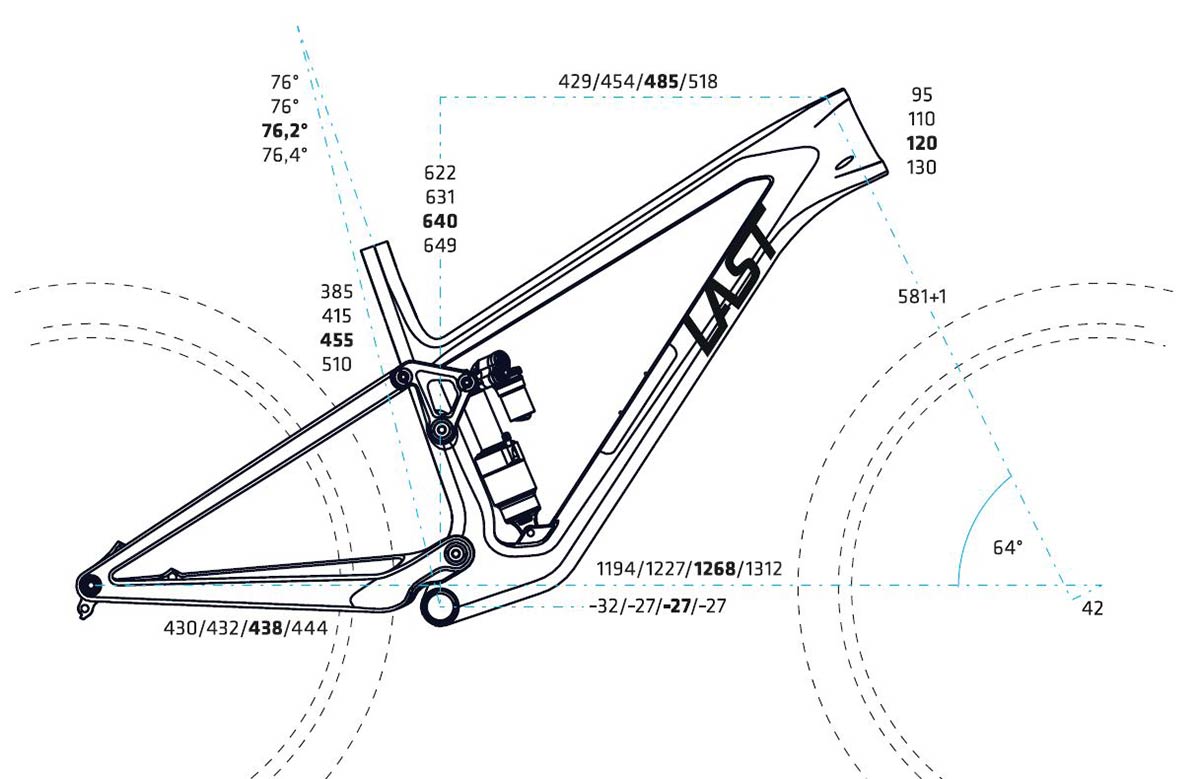

The Tarvo is available in four frame sizes; 165, 175, 185 and 195 – handily named after the recommended rider height in cm. The frames have a generous reach with figures spanning a range of 429mm to 518mm. A recommended 170mm fork sits at a head angle of 64° with a recommended 42mm or 44mm offset.

Chain stay length, seat tube angle, even BB drop vary across the size range. The 165 chainstay measures 430mm, increasing to 444mm in 195. The effective seat tube angle sits at 76° in 165 and 175. It steepens up ever so slightly in 185 and 195 to 76.2° and 76.4°, respectively.

All Last Tarvo frames have a BB drop of 27mm, save for the 165 which sits at 32mm drop. This is because the 165 will be spec’d with shorter 170mm cranks, given that is intended for shorter riders. The larger frame sizes get 175mm cranks so will need the additional ground clearance.

Tarvo Suspension Kinematics

The Last Tarvo suspension platform uses a flex pivot and a rocker arm. It is actually the first 160mm travel bike to utilize a flex pivot.

Wait. What even is a flex pivot? It simply means Last have done away with the seat stay pivot at the rear end. Instead, the suspension platform relies on the flex of the seat stays to go through its travel. Flex pivots aren’t new, but they are more commonly seen on shorter travel mountain bikes such as the Swarf Contour.

Last Bikes have been fairly generous with information, sharing with us the anti-rise, anti-squat and leverage curve graphs.

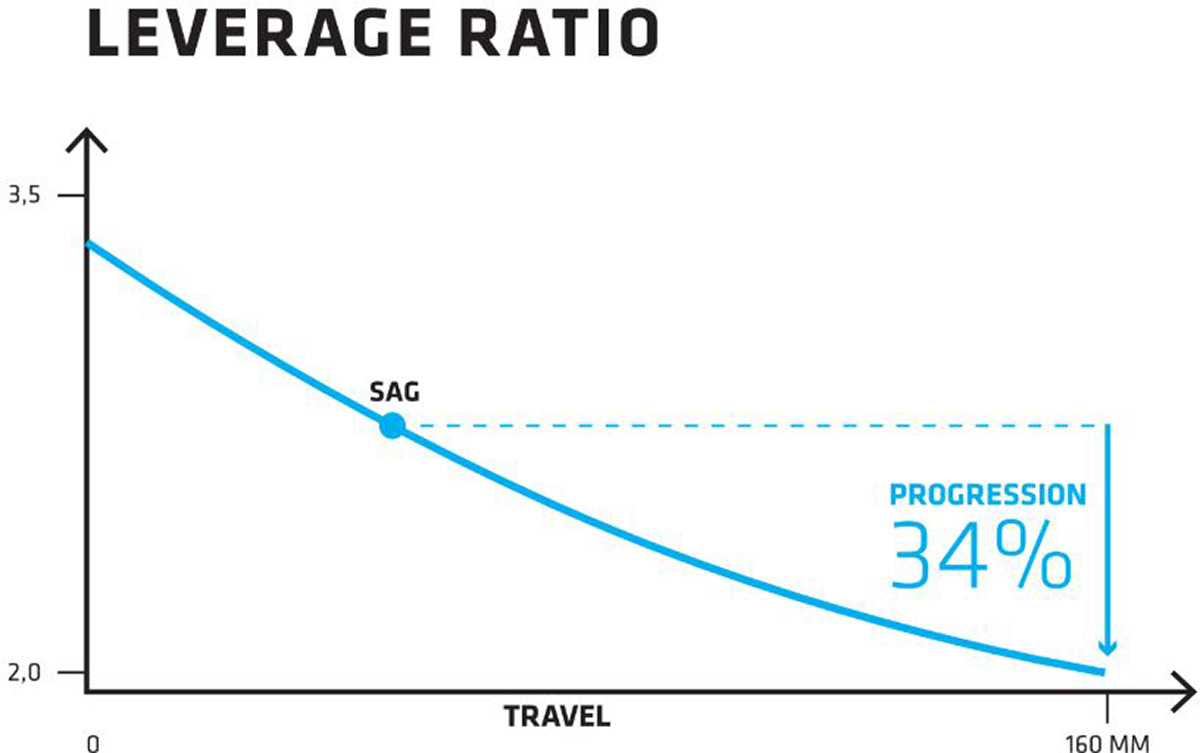

The Tarvo’s 160mm suspension travel has an overall progression of 55%. More important is the progression from the sag point to the end of the travel, which sits at 34%. Last Bikes say the progressive kinematics allow the use of both air and coil shocks.

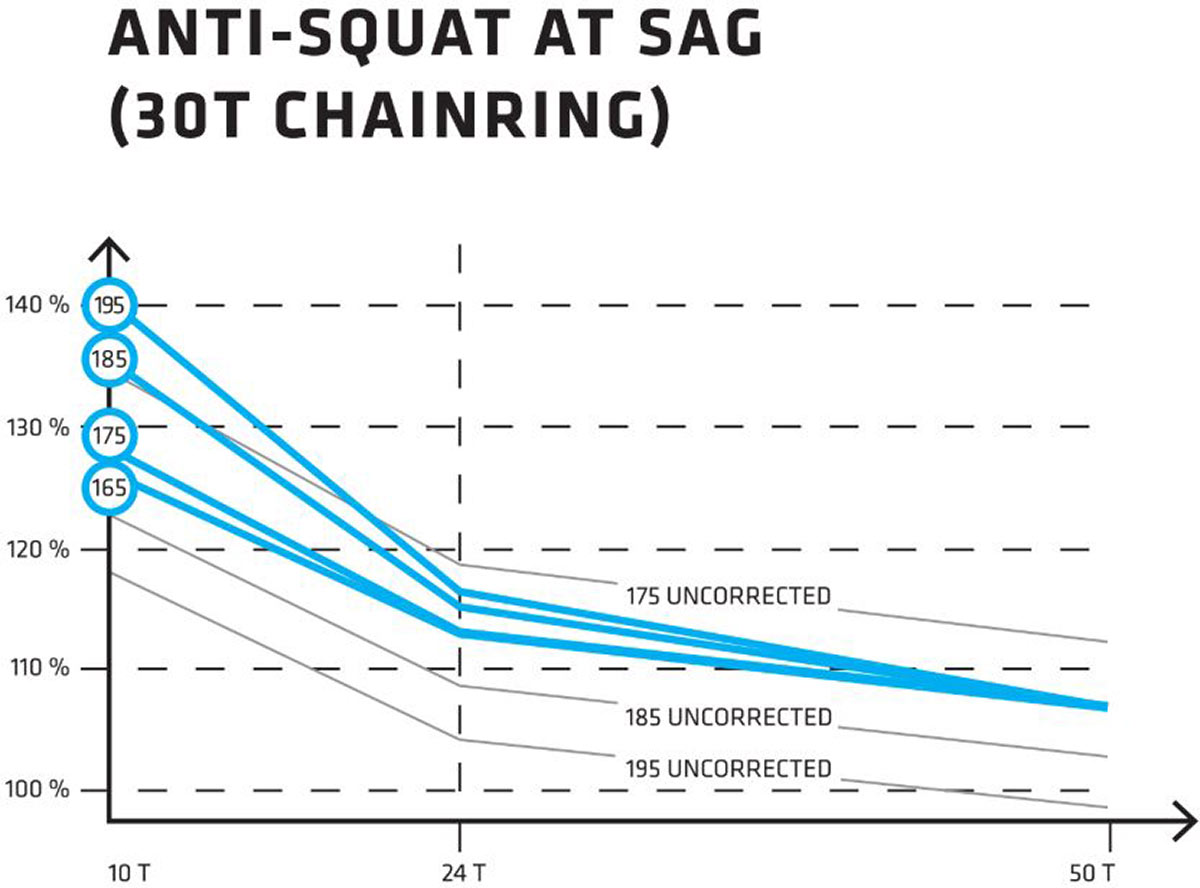

A bike’s pedalling efficiency is heavily influenced by its anti-squat characteristics. Last Bikes wanted each frame size to have optimal anti-squat values. To do this, they adjusted the position of the pivot points for each frame size and the expected height of the centre of gravity.

The blue plots show the anti-squat values for the four frame sizes depending on the rear cog (x-axis). For comparison, Last have also shown the values for a non-optimized or uncorrected system. It is easy to see that the blue lines are closer to each other, especially for low climbing gears.

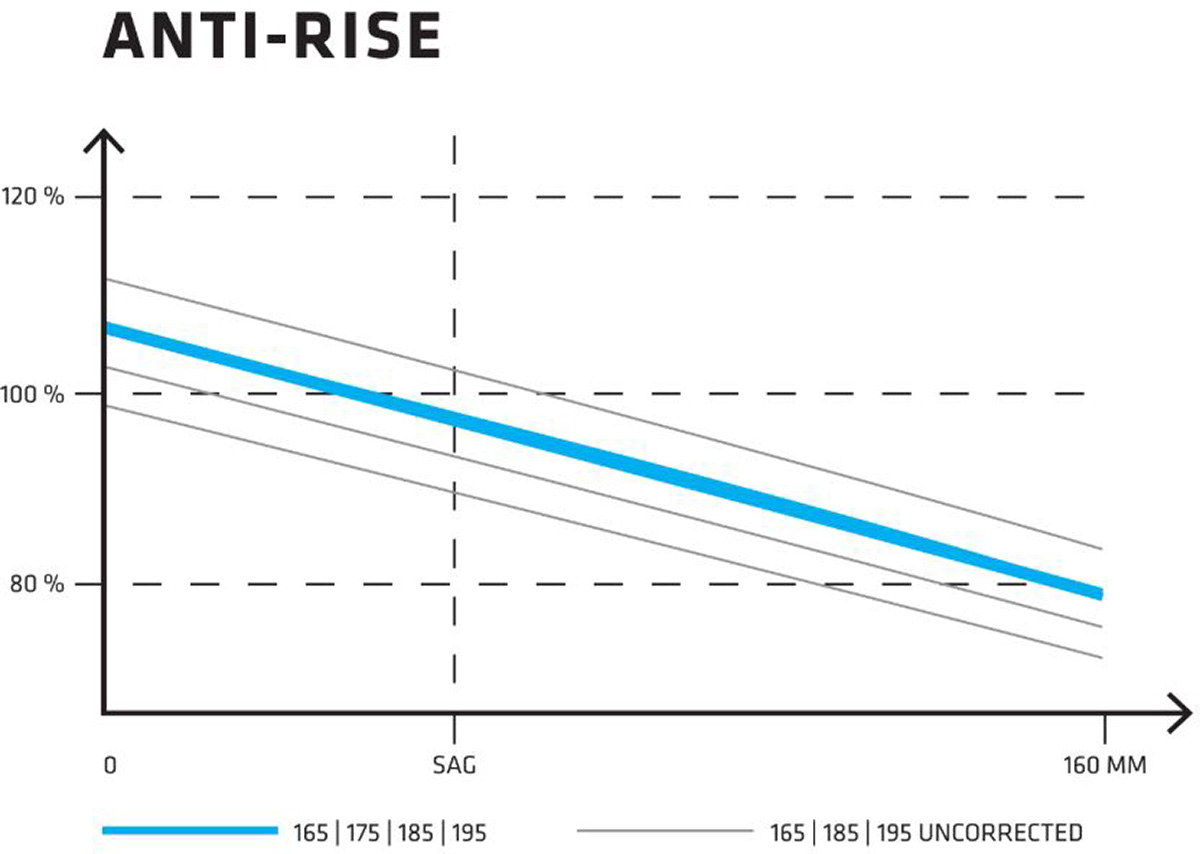

The anti rise value determines how the suspension behaves during braking. A value around 100% is considered the optimum, since application of the brake has no disturbing influence on the suspension system at this figure. The Tarvo’s size specific optimization results in four almost identical blue curves that appear as one thick blue curve in the diagram.

Carbon Tarvo Tech

The Tarvo is manufactured in a high-quality autoclave process as a monocoque without glue joints. The result is said to be a highly functional frame that is extremely light, yet low maintenance and extremely sturdy.

The Tarvo underwent demanding load tests at EFBE Prüftechnik. The result of these was the approval of the bike for use according to the highest category (5) of ASTM F2043-13, making the Tarvo a tested and safe lightweight construction according to the latest standards.

That means the Tarvo is considered safe for use in Bike Parks. The guys at Last are so confident in their design that they offer a 5 year warranty on the frame that applies to both original and subsequent owners. So what process created such a lightweight yet strong frame?

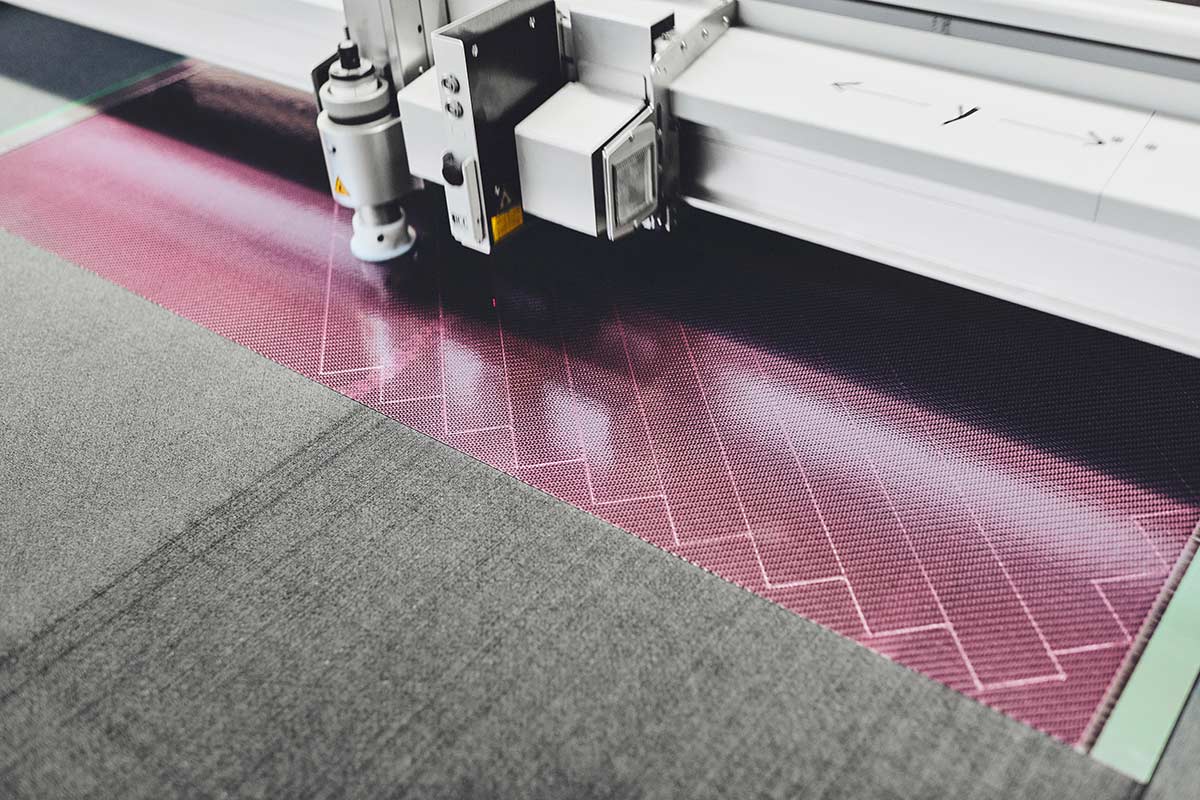

Last Bikes used Prepregs for the Tarvo layup. These are carbon fibre mats pre-impregnated with resin. The fibres of different stiffness are produced in Japan then processed into prepregs in Italy. The layup uses 90 degree and unidirectional layers. The guys at Last say sanding isn’t necessary after the process due to the high manufacturing quality. In fact, the visible layer of UD material is effective for load bearing.

The front and rear of the frame are each produced as a whole in one mould. The Last engineers say that due to the monocoque design, it features a consistent laminate structure without any weak points. Heavy joints where material is doubled up are completely eliminated.

An autoclave bakes the layered material under compression while a vacuum is created in the laminate to remove residual air.

Pricing & Availability

The Last Tarvo is available to order now with delivery expected in June. The 165 and 195 options are due in August. A RAW frameset without shock retails at 3,599 €. Get it with a Fox Float X2 shock, DHX2, RS Super Deluxe Ultimate Air or Super Deluxe Coil for 4,158 €, 4,288 €, 4038 € and 4,048 €, respectively.

The storage compartment is an optional extra at 199 €, as is the blue matte metallic finish for 399 €. Custom paint it any other color for 799 €.