We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. This one is about upside down suspension forks, also known as inverted forks. Hit the link at the bottom of the post to submit your own question!

Upside down forks, or inverted suspension forks are the norm in motor sport. We see them used in Moto GP, Motocross, on touring bikes, and pretty much every type of motorcycle in between. Why then, is this design so rarely seen in mountain biking?

If the upside down fork design works so well for motorcycles, what is stopping the major mountain bike suspension brands adopting the same design? We have seen a few of the major brands release inverted forks over the years. RockShox came out with the RS-1 in 2014, an upside down XC fork that is no longer in production. Why did the design never take off?

We sent this question along to many major suspension manufacturers, none of whom returned comment on the matter. No surprise really that the only brands willing to provide comment were those who currently offer upside down forks; Intend and Wren Sports. Here are their thoughts.

AASQ Inverted Forks

Upside down forks are very popular in motocross and on motorbikes across the industry, even in Moto GP. Why then, does the mountain bike industry use upright forks?

Intend: The reason in my eyes is the current public perception of upside down forks, which goes back to the first Marzocchi Shiver fork from back in the day. This fork was the first USD fork brought to a wide range of costumers.

The upside down design was new – right side up forks weren’t possible in the early days because of V-brakes. Human kind is always skeptical of new things, this is part of our nature.

With an inverted fork, if you put the front wheel between your legs and turn the handlebar with full power, you will always see movement. Because of this observation, riders are quick to judge that the fork is not rideable. But, the truth is, you will never get a load this high through the system while actually riding.

The observations from this simple off-the-bike test, combined with the general public perception that USD fork are bad, is the main reason the design has been unsuccessful historically.

The Manitou Dorado, the RockShox RS-1 and the latest entrant, the Magura Boltron – all of them were made with the knowledge that inverted forks have advantages over the right side up forks. Companies would not have tried it otherwise.

Wren Sports: That is a good question. My guess is that it was and is cheaper to build the upright style fork. It continues because many of the companies are heavily invested in tooling to make this type of fork. As an aside, we feel the inverted style fork is the “right side up” fork.

How does riding an upside down fork compare to riding an upright fork?

Intend: Upside down forks benefit from better lubrication of the bushings. They can provide a lot of stiffness back and forth and they have less friction at the bushings. This is because the bushings are moving down and this minimizes the leverage on the bushings when fully compressed.

So, the ride feel is more stable with reduced vibration because the wheelbase is not changing that much. The friction of the system is lower especially during heavy hits and you do not need to turn your bike upside down to lubricate the system.

Wren Sports: You will feel greater stiffness and stability when riding an inverted fork. This is especially true for hard chargers and for fat tire bikes where greater forces on the fork come into play. There are a couple of reasons for this:

- The inverted design moves the longer, stronger tubes to the top connected to the crown making for a very strong and stiff chassis. Upright forks position the stanchions at the top, which are the shorter, lighter tubes. The top of the fork is key to absorbing the forces entering from the axle. A stronger chassis is a big advantage.

- The inverted design moves the shorter, lighter tubes to the bottom, reducing the moving weight of the fork. This allows our fork to move faster and easier to changing trail conditions. This keeps the tire planted. Also, having the shorter tubes on the bottom reduces the leverage factor. Typically, a fork can flex where the two tubes join.

Our shorter stanchions reduce the forces acting on this junction point and allows the stronger, stiffer chassis to easily absorb them. The longer, lower tubes on an upright fork can amplify these forces asking the weaker chassis to absorb them. Just put an inverted style fork next to an upright fork and you can immediately see these advantages.

Do inverted forks have a shorter service interval than regular upright forks? Seems to me the seals would be more exposed as they are closer to the trail.

Intend: No. My experience is that the overall service intervals are equal. The main problem is the loss of oil from the inside to the outside and the amount of dirt coming in to the system.

Using the same seals, I had dark oil with uspide down and right side up forks after several month of hard riding. The seals of the inverted fork are lower, but you also have no dirt coming from the tire to your upper legs. So, in total there is no difference.

Wren Sports: We recommend a complete clean and lubes every 100 hours of typical riding. More often if you ride in dirty, muddy, wet conditions. We use a maintenance-free all-weather sealed damper cartridge, so no damper maintenance is necessary.

The wipers would seem to be more exposed because they sit lower on the fork. However, our wipers face down allowing for improved cleaning of the stanchions with each stroke with the help of gravity. The wipers/seals on upright forks face up allowing dirt and moisture to collect and sit there. Eventually, each compression stroke can then suck dirt and moisture into the fork.

Would inverted fork technology work better for long travel enduro/DH bikes than short-travel XC bikes?

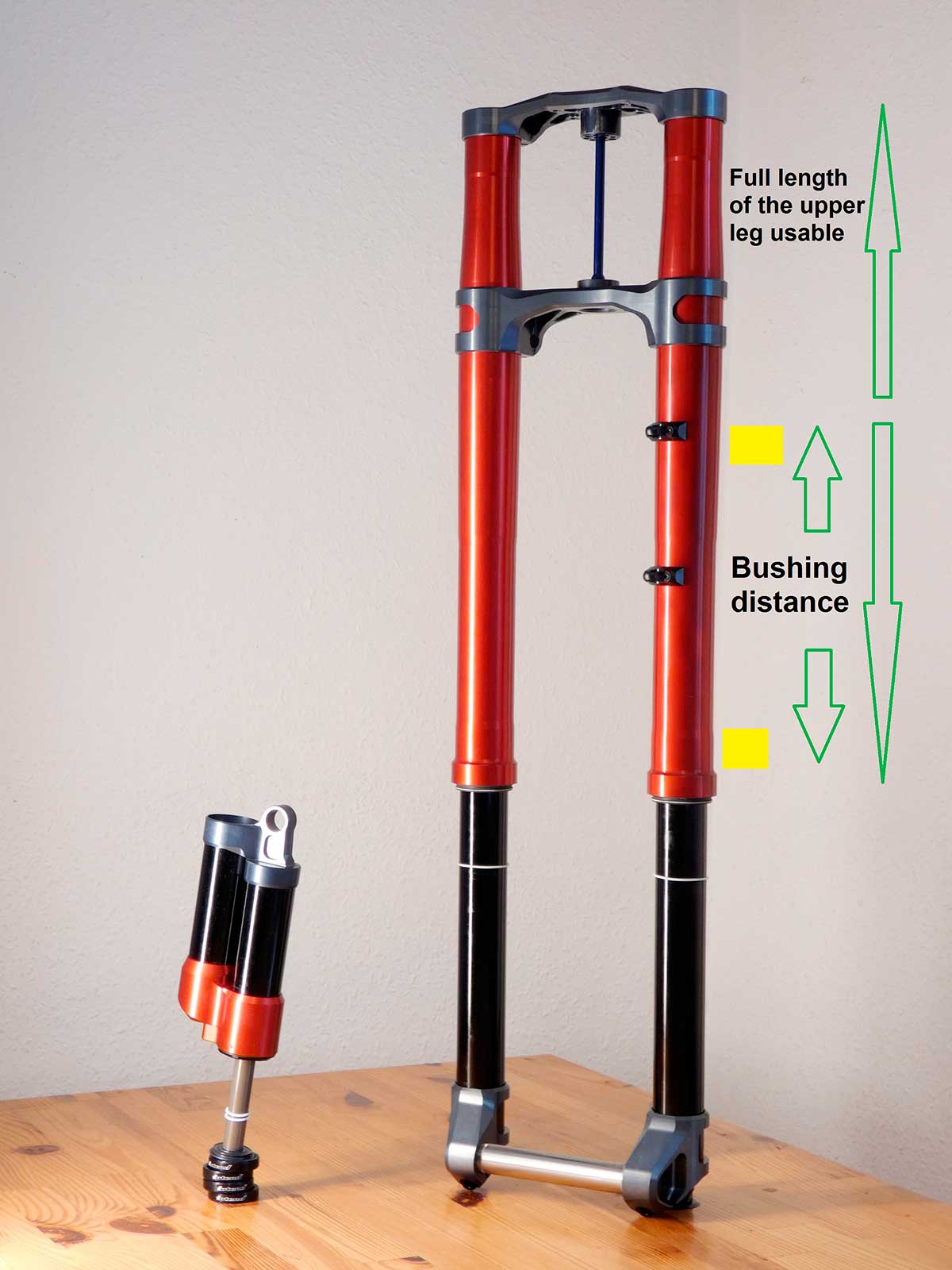

Intend: Upside down fork technology especially has benefits for dual-crown forks, because you can extend the distance of the bushings up into the full length of an upper tube.

With a normal lower casting you are limited with 200 mm travel and the length of the casting (can’t be made that long). So, bushing distance with inverted dual-crown forks is approximately twice as much, leading to a reduction in friction of up to 50%.

Wren Sports: We feel the added strength and stability of an inverted style fork is an advantage for all types of riding. The disadvantage of inverted style forks historically has been torsional movement. Wren use a key system to prevent this movement from affecting the performance of the fork.

How does the damping work on an upside down fork?

Intend: The damping function has no difference to other forks.

Wren Sports: The damping function basically works the same across all suspension forks. The design of the damper differs between manufacturers. The damper controls the movement of the fork by controlling rebound speed. Without damping, you would essentially be riding a pogo stick.

Thank you to Cornelius Kapfinger of Intend Bike Components and Russ Johnson of Wren Sports for contributing to this week’s Ask A Stupid Question!

Got a question of your own? Click here to use the AASQ form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!