What does the future of helmet design and manufacturing look like? We might already be seeing it through the work of London’s HEXR. From the raw materials, to the construction, the fit, and the safety claims, HEXR offers a futuristic take on the traditional bicycle helmet.

So what is the HEXR made out of? Beans. More specifically, the castor bean which is then used to create castor oil which is processed into Polyamide-11. The material promises a more environmentally conscious helmet construction, as well as claiming to be ethically sourced through the Pragati initiative. The material is also said to offer 8x better thermal conductivity than foam which HEXR claims will help pull heat away from your head to be vented out through the channel under the shell.

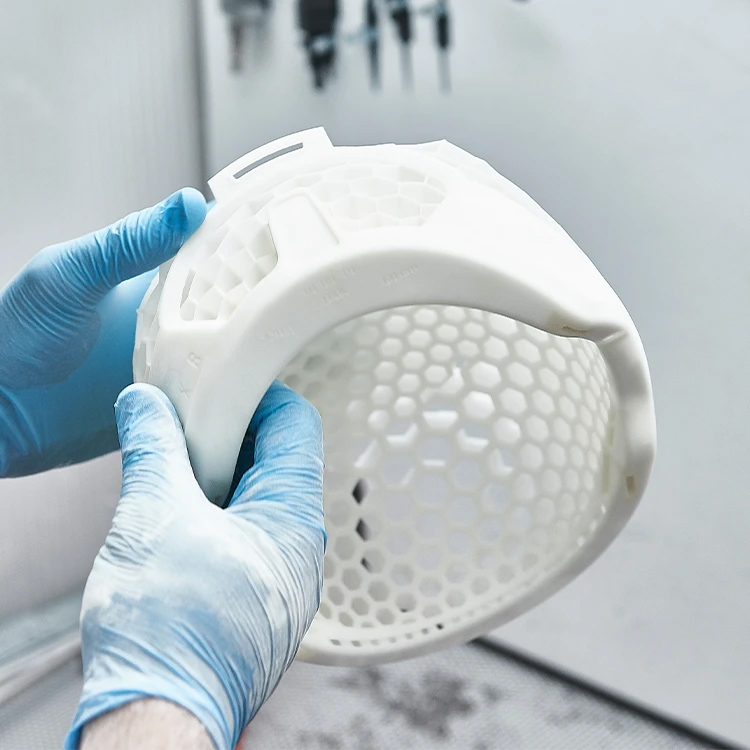

That castor bean oil is then transformed into powdered form and 3D printed using the laser sintering process by 3T Additive Manufacturing Ltd in Newbury.

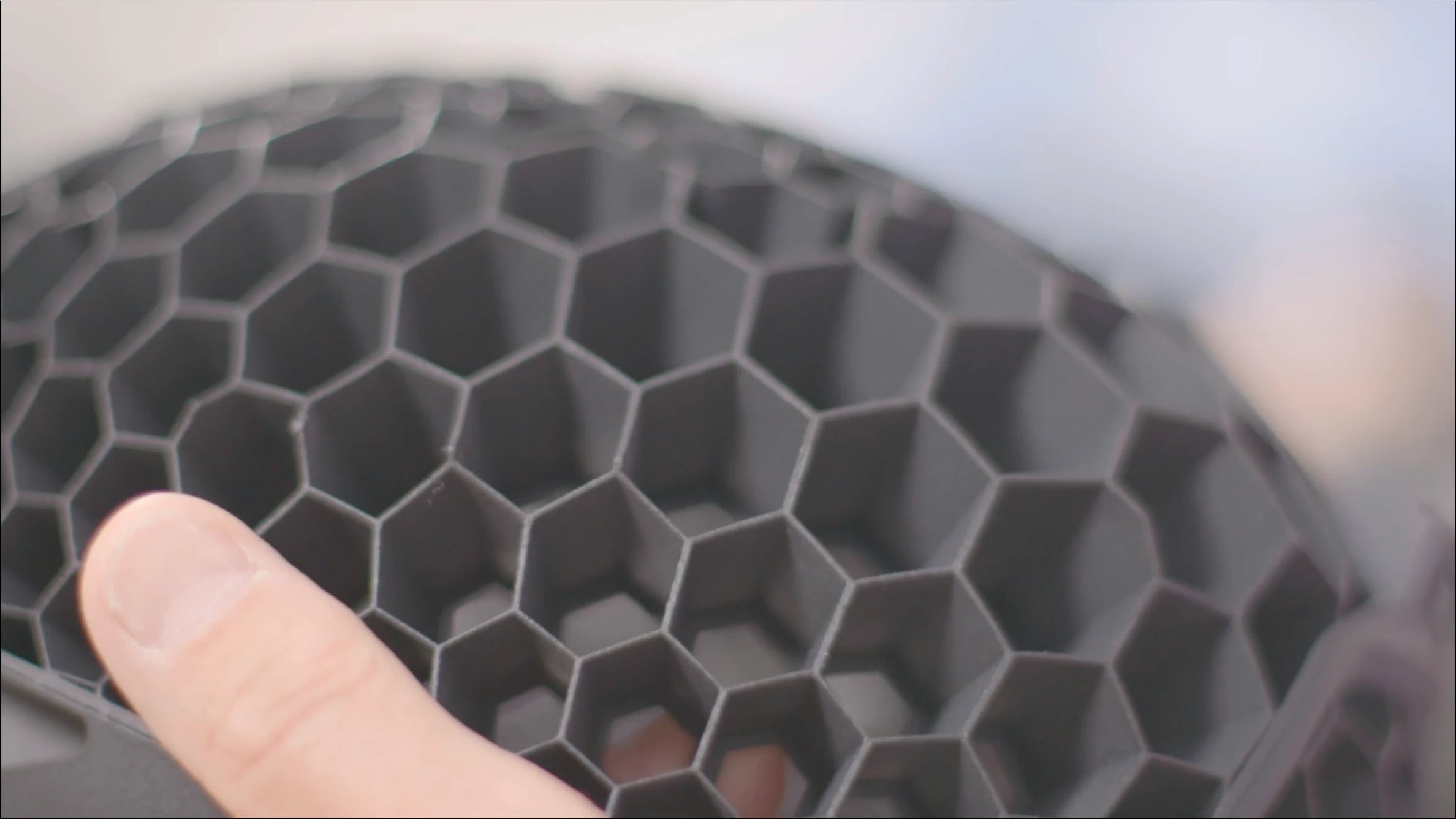

When it came to designing the helmet’s ability to absorb impacts, HEXR’s founders decided that the best way forward was 3D printing or additive manufacturing, stating “we need to design for the head’s unique curvature. The only way to make a curved honeycomb structure without distorting the mechanical properties is by 3D printing.”

Once finished printing, the helmet’s core is then dyed black to protect the material from UV rays, and paired with an external shell. That shell expands on the safety aspect of the helmet by adding a rotational component in addition to the energy absorbing honeycomb. In the event of a crash, the front plug will detach and the outer shell will rotate while the inner structure crumples to absorb impact.

HEXR claims that their helmet was independently verified at the University of Strasbourg by Professor Remy Willinger, and offered an average “30% improvement in rotational velocity, acceleration, and linear acceleration.” This testing was supposedly performed against 40 other helmets, 15 of which had MIPS, and one was equipped with Wavecel.

In addition to the unique construction and safety aspects of the helmet, 3D printing allows another interesting angle – custom fit helmets. But how do you go about fitting people for a custom helmet around the globe?

In addition to the unique construction and safety aspects of the helmet, 3D printing allows another interesting angle – custom fit helmets. But how do you go about fitting people for a custom helmet around the globe?

With a smart phone of course.

The most recent piece of the HEXR puzzle is their smartphone app-based fitting program. Once you’ve purchased a helmet, HEXR will send you the fitting cap which is used in conjunction with the app. Put on the cap, hand the phone to a friend, and have them scan your head. Once all the segments turn green, you’re done. The file gets sent to HEXR, and you get sent a custom fit, 3D printed helmet.

Apparently, there are 6 sizes of the outer shell, and your helmet will be custom printed to fit within the shell that offers the best fit – so there are some limitations to the design. The final fit will offer additional room for your hair and for adjustment with the removable dial fit system, but the overall shape will be custom fit to you. HEXR states that winter caps can still be worn underneath, but you’ll likely have to remove the padding from the helmet for them to fit.

Of course, all this tech doesn’t come cheap. Currently, the HEXR is priced at £299 (~$405). That’s a lot of beans. But not only is that a custom fit helmet, HEXR will allow you to personalize it for free with text engraving of your choice. Shells are available in white or black, and HEXR offers a 50% crash replacement policy for the first year. For more details, check out HEXR’s FAQ section linked below.