Back in 2019, we visited 3T to get a first hand look at how their Torno carbon cranks were being produced. While the emphasis was on the crankset construction, 3T hinted that Italian-made frames would be a possibility some time in the near future. The pandemic may have slowed things down a bit, but 3T has just officially announced their move into Italian-made framesets, and they’ll be offering a Founders Edition to celebrate.

Dry Fiber with Resin Injection

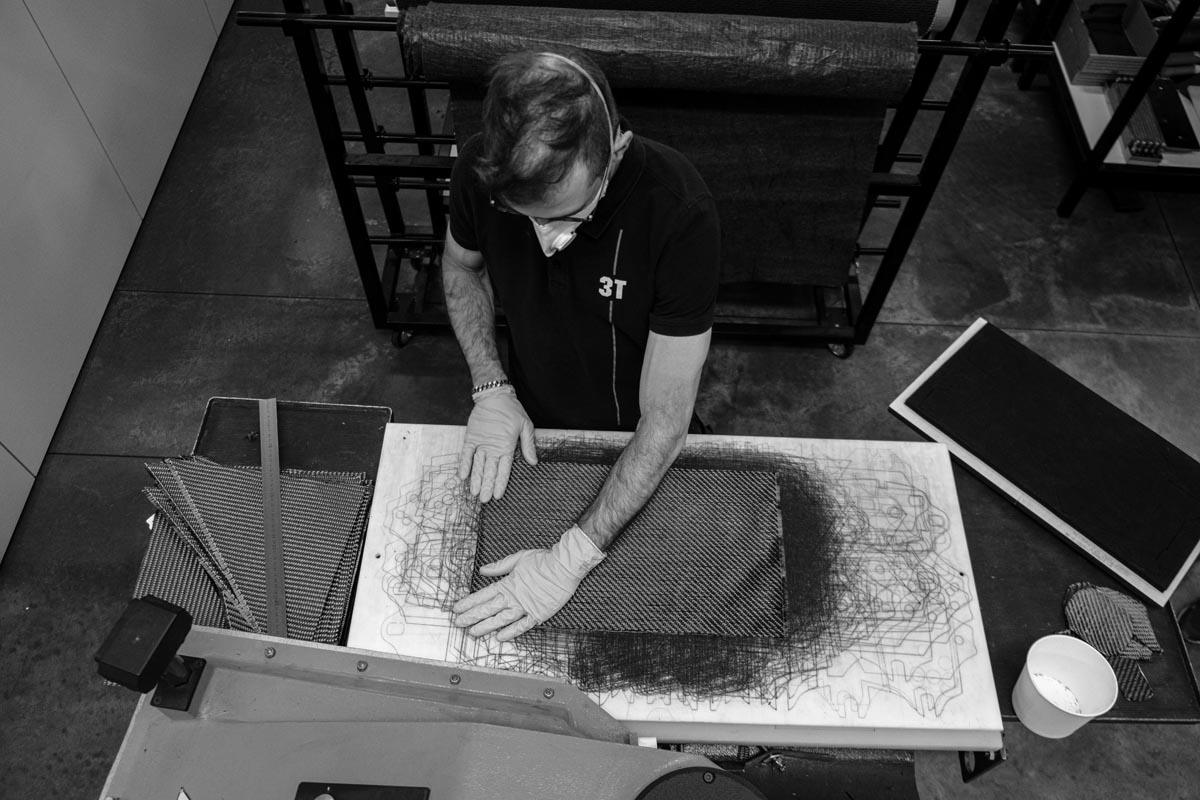

Just how do you go about making your own carbon frames in house? For 3T, it was a step by step learning process which started with the Torno crankset. To keep things simple, the Torno started with more standard carbon fiber sheets, but with so called ‘dry fiber’. That means that unlike preimpregnated carbon fiber, the resin hasn’t been added yet. 3T claims that this allows for the creation of more complex shapes, while also opening up more types of carbon fiber to be used.

Another big advantage is that dry fiber frames can be placed directly into hot molds without the resin starting to immediately cure. This saves time and energy from constantly warming and cooling each mold before use. Then, once the frame is inside the mold, the resin is injected and cured, which with the right technique, results in a better surface finish without the need for huge amounts of hand finishing.

Filament Winding

Additionally, the dry fiber has advantages that 3T was planning to utilize when they made the move to frame production. Deciding that filament winding was the way to go to create carbon layups without limitations for fiber angles, they have gone to great lengths to develop their own custom filament winding machines.

Additionally, the dry fiber has advantages that 3T was planning to utilize when they made the move to frame production. Deciding that filament winding was the way to go to create carbon layups without limitations for fiber angles, they have gone to great lengths to develop their own custom filament winding machines.

By using dry fiber, 3T says that they have access to “every grade and type of carbon fiber” as a dry fiber yarn. That gives them more options when it comes to the exact type of carbon fiber used in the frame production, and helps them configure their ideal layup and ride qualities.

3T points out that the filament winders shown above are prototypes – they’re not showing the final versions. For obvious reasons.

First Frames

In 2019 (right around the time of Cory’s visit), they started the development of their first carbon frame – the Racemax Italia. They figured that if they could create a lighter frame than their current top of the line option with the same stiffness and strength, they could do just about anything. Now, that dream has become reality.

Founder’s Edition

To celebrate the occasion, 3T is offering the first 100 Italian-made frames as a special Founder’s Edition. Well, the first 99 frames – frame #001 is going into their museum.

These very special bikes will be sold as a frameset with fork, seatpost, and some special Founder’s Edition touches:

- Engraved metal limited edition plaque with frame number

- Custom see-through paint options

- 2 finish options under the see-through paint (standard or industrial carbon finish, see below)

- Customer’s name under the clearcoat

- 1X+2X frame or dedicated 1X frame (perfectly smooth seattube without any inserts for an FD mount)

3T promises more details and photos at a later date, but they point out that bikes will be delivered in order, so the earlier you get your order in, the sooner you’ll get the bike. The Founders Edition can be ordered from 3T’s top Experience Centers and from 3T directly for USD $5,999 (+tax) / EUR 5,999 (incl. tax) / GBP 5,499 (incl. tax). The link below has a contact form for 3T for more details, with production slated from now through October.