As we’ve seen the rapid prototyping concept grow technologically into an actual method to manufacture components, a lot of design limitations that have previously governed bike design start to disappear. Bike shapes can become more fluid or flexible, and things like custom geometry full-suspension bikes can become reality. One such promising bike is the new R160 from the young Robot Bike Co.

The 160mm travel trail bike starts with a set of 11 individually made-to-order 3D printed titanium lugs that get heat-treated, precision machined out, and joined up to 8 carbon fiber tubes to build a unique bike for each customer. With Dave Weagle onboard as a founding company partner, the R160 gets shaped around a progressive DW6 suspension design to give it the confidence to fly over steep and technical trails, while still pedal well enough to get back up the hills and enjoy all-day adventures. Drop past the break for a close look at the new bike…

Formed back in 2013 as a partnership between a handful of engineers, designers, and frame builders plus suspension guru Dave Weagle, Robot sought out to build lightweight custom geometry full-suspension mountain bikes that would truly be tailored to the individual rider. With really technical backgrounds in titanium and carbon, 3D printing or rather ‘additive manufacturing tech’, frame building, and suspension design, the Robot team had the technical know-how to build something truly unique.

The resulting R160 is Robot’s first and currently only bike. But they don’t really seem worried by that. With a new DW6 suspension design and sure to fit custom sizing, Robot is confident that the bike can serve everything from all-day epic trail riding to proper aggressive enduro racing. The heart of that is suspension designed with a progressive leverage ratio that aims to deliver a supple start of the travel to maximize grip, ramped up support in the middle for a more linear feel and stable pedaling on everything from small to medium hits, and a seemingly bottomless end of the travel for confidence when things start to get out of hand.

The bike uses 27.5″ wheels with a 12×142 (not Boost) rear end and sticks with a standard 73mm threaded bottom bracket for trusted reliability. That is where threading of the ti lugs ends, though. The rest of the bike, and most importantly suspension pivots, forgoes threading the frame, but instead using captive threaded hardware. That way you’ll never have to worry about stripping the threads out and ruining a frame. Any problems, and you just replace some hardware.

Key to the feel and function of the bike is the custom fit and geometry. All the effort that Robot put into developing the tech could be worthless if the bike didn’t fit well, and that’s why they believe so much in the custom fit. The unique lugged construction and parametric design tool they’ve developed lets Robot and their engineering partners quickly generate the lugs from individual rider fit.

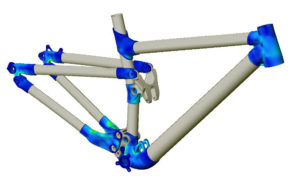

The root of the frame’s construction is of course the titanium additive manufactured lugs. By pulling tech from aerospace manufacturing, Robot gets the flexibility to shape the 6-4 ti specifically to handle the more complex loading at the tubing junctions and suspension pivots. The Selective Laser Melting process also gives them the precision to create a double lap joint that better locks onto the carbon tubes without the need for extra wasteful resin, and actually ensures better resin coverage through it precise shape.

Once Robot has each rider’s measurements they work on tailoring the geometry to you. The have a basic set of guidelines that they work from, but are happy to work with any rider who wants to further tune the ride for their own mix of a blend of speed, fun, stability, and agility.

The standard bike starts off with a recommended head angle of 65.5°, seat angle of 73.5°, 430mm chainstays, and 10mm of bottom bracket drop. The R160 uses a tapered steerer headset, gets ISCG tabs, and uses a 31.6mm seatpost, with stealth dropper compatibility. The frame uses a 216 x 63mm shock and M8 x 22mm shock hardware. Pricing is set at £4400 for the custom fit frame, with options for builds limited only by your imagination and budget.