We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Welcome back to the Bikerumor Ask A Stupid Question series. This week, we’re tackling your questions on all-important braking power with the help of experts from TRP Cycling, Magura, Hayes and Galfer. Brake fade and the perils of rapid cooling are up for discussion, with the guys from TRP Cycling sending in some cool videos to show their in-house testing, so make sure you scroll down to see those!

We also asked a bonus question… “Will we ever see double disc front brakes in DH?”. What do you guys think? Stick your thoughts in the comments below.

Answering your questions this week are the following experts:

- Ricard Bages of the R&D department of Galfer

- John Thomas, Chief Brake Engineer at Hayes

- Sean Doche, Marketing Coordinator at TRP Cycling

- Jude Monica, Technical Service Manager at Magura

I’m struggling with braking power. Brakes are not as sharp as they used to be and they suffer badly from fade on moderately long runs. Has the scoring from getting hot over countless cycles now impacted their ability to brake well given the disc surface is “damaged” due to heat?

Galfer: Most of the brake pads are based on an organic compound, even those that contain metallic particles. After an overheating season, friction material rust, losing friction performance. That effect can be perceived easily on cheap pads.

Trust quality brake pads. They can withstand very high temperatures without an irreversible drop in brake performance. It is very difficult to damage a well-tempered disc due to braking heat.

Hayes: Brake fade is not related to the scoring of the disc surface. Fade performance is dependent upon the friction material, the brake caliper, and the rotor. The thermal capacity of the brake caliper and the rotor contribute to the temperature that will be reached in braking.

The friction material itself has a fade performance which essentially is the drop in power during heat cycles; the smaller the drop the better the fade performance. This fade performance can be worse with improper burnish.

Of course, contaminated pads will perform even worse. We would recommend new pads that are properly burnished on a clean rotor. If fade is still a concern you can move up in rotor size to improve the performance. Selecting a brake system with a larger thermal capacity will also improve performance further.

TRP: Cycling: If you are struggling with braking power and brake fade over long descents, it really comes down to the heat management of the system. From what it sounds like, your pads and rotors have reached their temperature limit, termed by us as “the fall off”, and are damaged.

Braking performance is highly dependent on the friction surface between the pads and rotor and if the rotor track has been heated to the point of scoring and discoloration, then it is likely that both the pads and rotor have reached the fall off point and are equally damaged by glazing.

This happens when a pad reaches its maximum temperature threshold and the pad surface begins to melt onto the surface of the rotor thus transferring super-heated material into the striations of the bedded rotor creating a smooth-on-smooth surface which takes away most braking friction. Even if installing a new set of pads, the damage to the rotor will be difficult to remove and it will negatively impact braking performance.

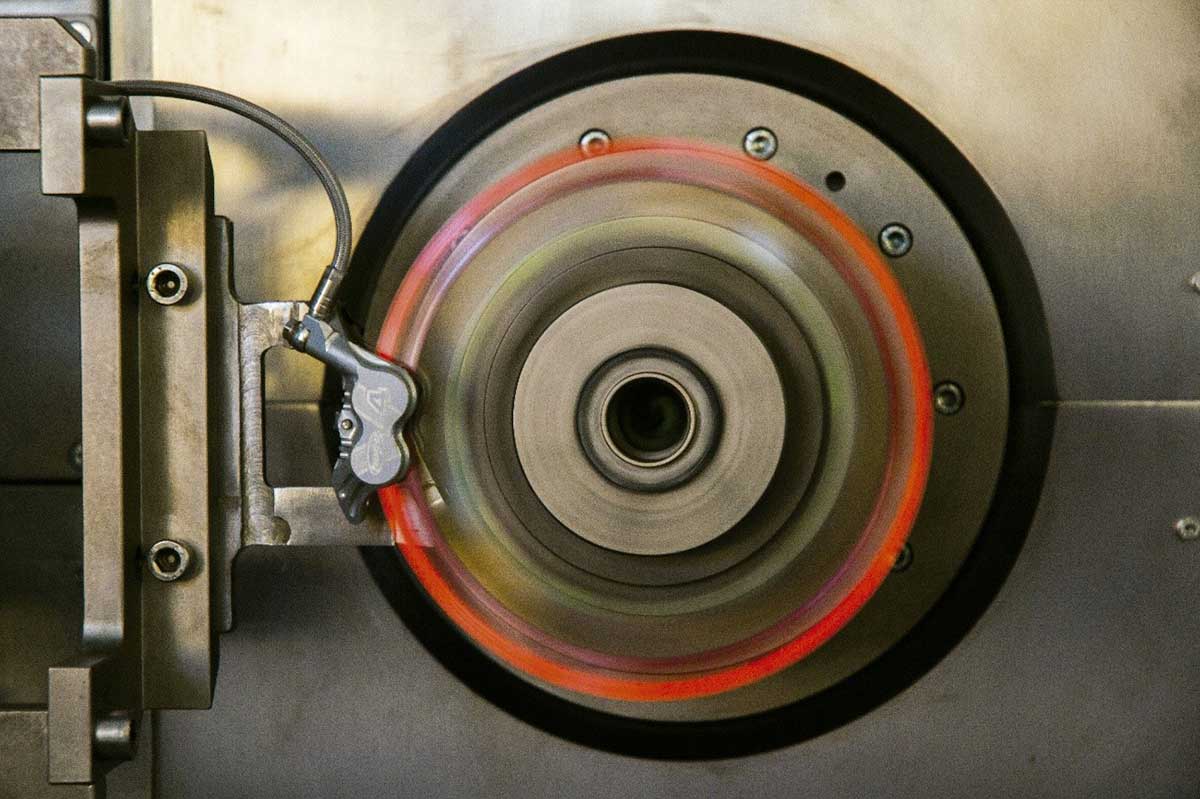

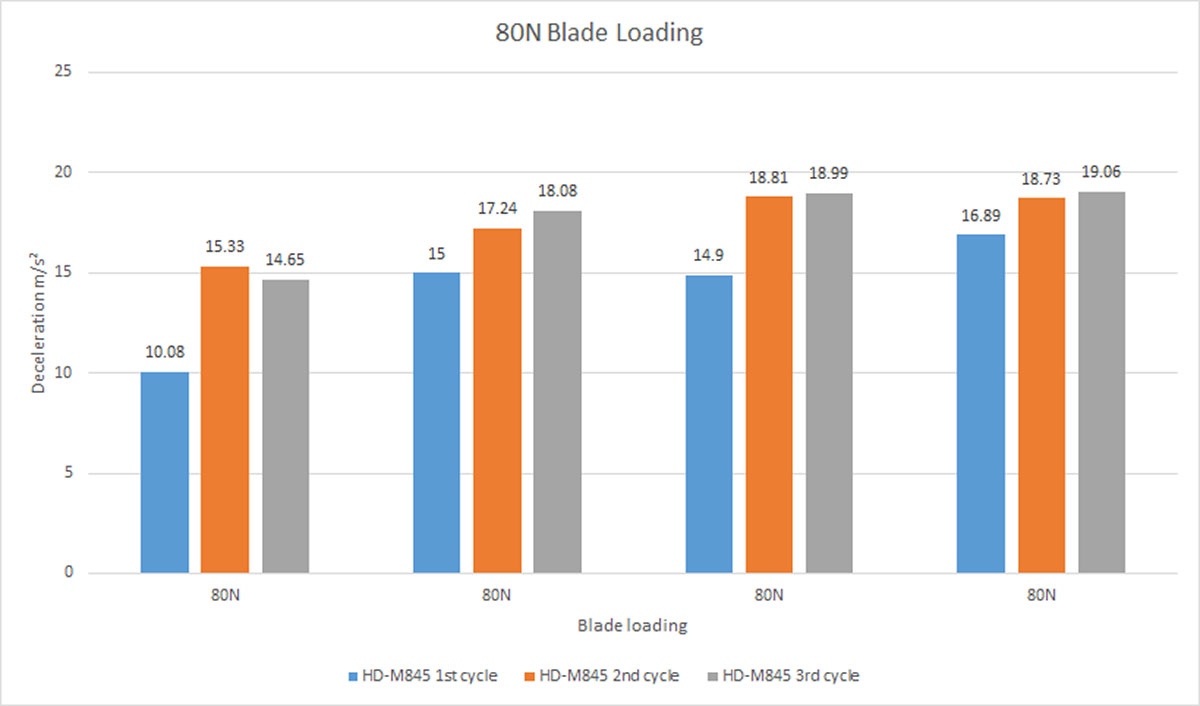

Testing the Gold DH-R EVO caliper for heat stability during deceleration in the dynamo at the Tektro Technology R&D Laboratory. Even at these temperatures, braking performance remained constant and the power actually increased with each pass. See the below for the results.

Magura: We are talking about heat management so, firstly, DOT fluid’s performance will deteriorate with the attraction of moisture but this is only part of the problem (mineral oil does not deteriorate).

Secondly, the rotor becomes thinner with wear and is not as effective at controlling temperatures. Next, if mixed brake pad compounds have shared the same rotor, this can contribute to the problem. If the brake pads/rotor were bedded-in and heat cycled improperly originally, this can be part of the issue.

Otherwise, no. They should always be able to return to top performance. That may include a bleed, new rotor and fresh pads.

Is it a coincidence that I see a decrease in the performance of my brakes after squirting the rotors with water to cool them down after a long descent?

Galfer: We do not recommend that riders quickly cool the disc using water. When you stop braking, the disc cools down so fast with just the air.

But, the decrease in performance could be caused by a chemical reaction over the pad material that is caused by the addition of water. Continuous mud and dirt are not a problem because the water in the mud also helps to cool the pad material. But, when the pad is dry and very hot, it is easier to damage some compounds.

Hayes: The friction material in a brake will perform differently in dry vs wet conditions. However, the wet performance is temporary, and the friction material will recover once dry. If the brakes were only splashed then the water will vaporize quickly and dry performance will return, but if it is raining then the wet performance will continue.

It is not necessary to cool the brakes with water, they will cool on their own. If you do squirt the rotors with water you must be careful not to wash any contaminates into the brakes! This would cause a permanent decrease in performance.

TRP Cycling: It is definitely not a coincidence that you see a decrease in performance after dousing the rotors with water because, interestingly enough, it will aggravate the problem even further. When you do this, it is not letting the pad or rotor cool in a proper manner, thus effecting the composition of both surfaces.

Think of a glass filled with boiling water. If you empty the boiling water and pour in cold water, it will cause premature contraction and shatter the glass. This is essentially what is happening when you douse a brake with water after its heated from a long descent. The pad contracts in an uneven manner causing material separation or a type of glazing.

The material bedded into the rotor will unbind as the metal and deposited pad material cool at different rates, and you can stress the metals in the rotor and cause warping, cracking, or in extreme cases, it can even a change the temper of the material. AKA, don’t douse your rotors or calipers with water to cool them down after a long run as your rotors are designed to cool at normal air temperatures.

Rapidly cooling the caliper, rotor, and pads by dousing with water after testing heat stability during deceleration in the dynamo at the Tektro Technology R&D Laboratory.

Bottom line, this is a heat management issue that you are facing and that is the number one reason why TRP started using thicker rotors, higher volume calipers, and a mineral oil with a higher boiling point since 2017.

These solutions give TRP EVO brakes a much higher temperature threshold allowing their performance to remain more consistent under intense usage and making them safer for a heavier DH, Enduro, or E-MTB over a long descent and that is proven from the results above.

Magura: Yes. that is a problem because you are “hardening” the pads’ organic materials (think quenching a metal from forging as heat treating, similar) as opposed to riding in the rain as the rotors wouldn’t experience such a sharp drastic temperature change at once. Basically, you are altering the designed friction coefficient.

Will we ever see double disc front brakes in DH?

Galfer: This is a solution that comes from the motorcycle industry. It is a very effective way to achieve a high braking power with good thermal management. From the point of view of friction elements, it is a fantastic solution. But, we also think that bicycle systems should be as simple as possible.

A main difference between bicycles and motorcycles is not just the caliper size, it is also the piston caliper spring back. On motorcycles it is not a problem that pads touch the disc while they are not braking. On a bicycle, we need considerable piston retraction to avoid noises.

The initial free lever stroke is related to that retraction because the master cylinder must push oil into the caliper pistons before the pads touch the disk. It means that, for a single caliper to run off the same same lever, the free stroke distance would need to double. A specific master cylinder would be also needed for a double disc system.

Off-road motorcycles are not using double discs despite them being heavier than e-bikes, and the braking capacity is optimal. In our opinion, disc thickness on DH bikes should be increased to get more stiffness in big sizes and better thermal capacity.

The Ø223 discs could become standard for all DH forks. That would avoid the use of adapters. In this way, the pad width should be increased to reduce the contact pressure for more friction and reduced temperatures.

Hayes: We are always developing brake technologies and some ideas have not made it into production for various reasons. I can’t comment if we are specifically developing double disc front brakes but consider that it must have enough of a performance advantage to justify the cost, weight, and setup penalty.

TRP Cycling: We (racers) tried dual front discs back in the 90s when the power was lower and there were fewer disc options. It proved more trouble than it was worth and better equipment soon followed as the current 4-Pot offerings are more than enough to slow things down on today’s bikes. If you need more stopping power after all of the above, you might consider bumping up a disc size to increase the leverage over the wheels.

Magura: Quite possibly, as there are advantages for suspension action. The bushings experience a lot of torsional rotation and binding (stiction) and loss of suppleness during braking. More weight and speed equal more forces needed to slow a bike down so then we will see the need for more and more. Possibly starting with eBikes or cargo loads.

Editor’s Note: We also sent this question out to Campagnolo, who are developed a double disc front brake for a special edition special edition Colnago V3RS DV. They are yet to provide comment, however.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!